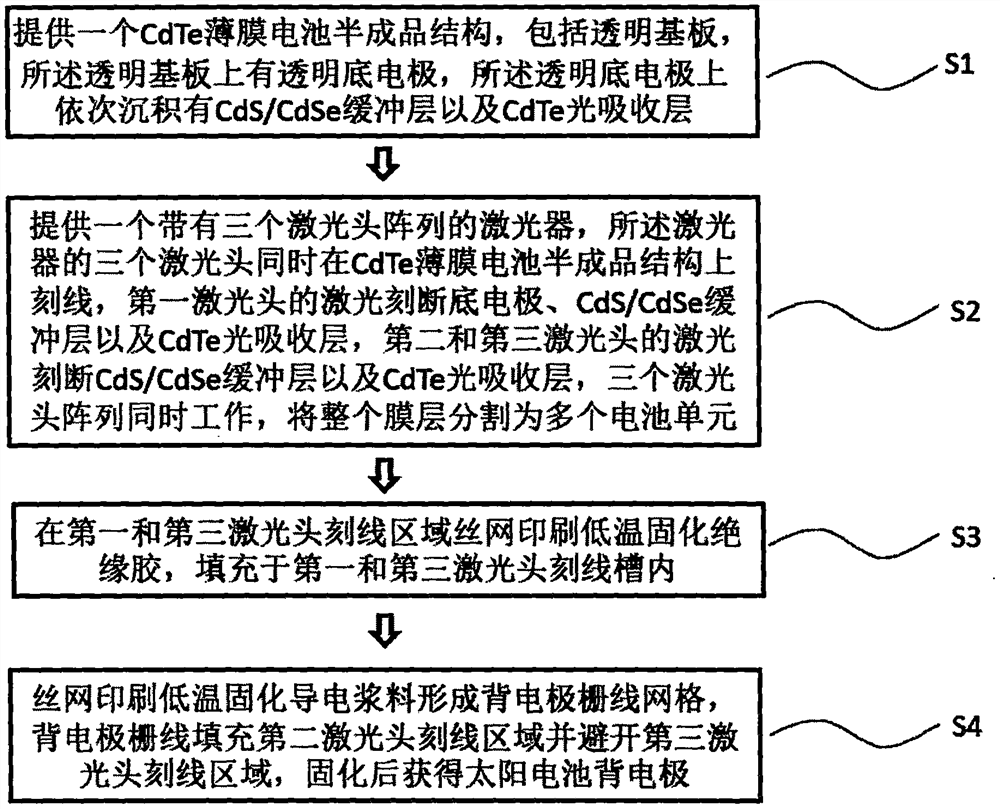

Method for manufacturing back electrode of CdTe solar cell

A technology for a solar cell and a manufacturing method, which is applied to circuits, electrical components, photovoltaic power generation, etc., can solve the problems of waste of photoresist, lengthy and complicated laser engraving process, etc., so as to improve the precision of engraving, improve the yield rate, and simplify the process. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

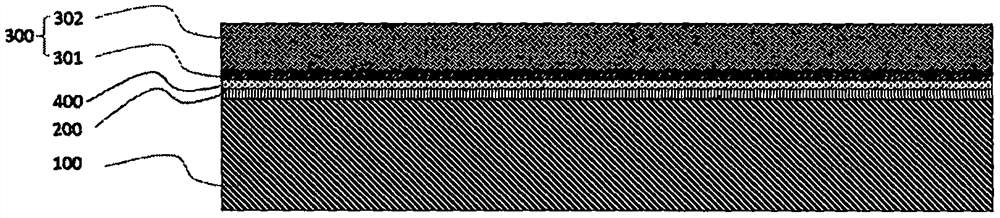

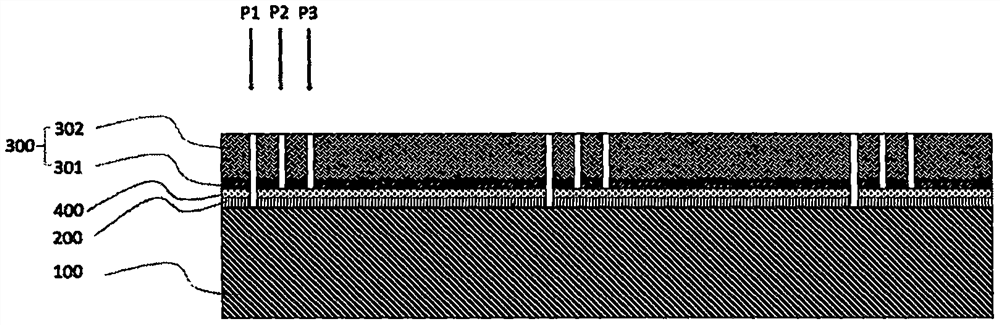

[0030] The embodiments of the present invention will be easily understood by those skilled in the

[0031] As described in detail the embodiments of the present invention, in order to facilitate explanation, the cross-sectional view representing the device structure is not in general ratio, and the schematic diagram is merely an example, which is not to limit the scope of the invention. In addition, the three-dimensional spatial dimensions of length, width, and depth should be included in the actual production.

[0032] For convenience of description, there may be a space relationship word such as "under", "below", "lower", "below", "above", "upper", and the like may be used to describe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com