Flexible CdTe (Cadmium Telluride) film solar battery and preparation method thereof

A technology of solar cells and thin films, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as difficulty in large-area preparation, complex production process, and difficulty in stably controlling film thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

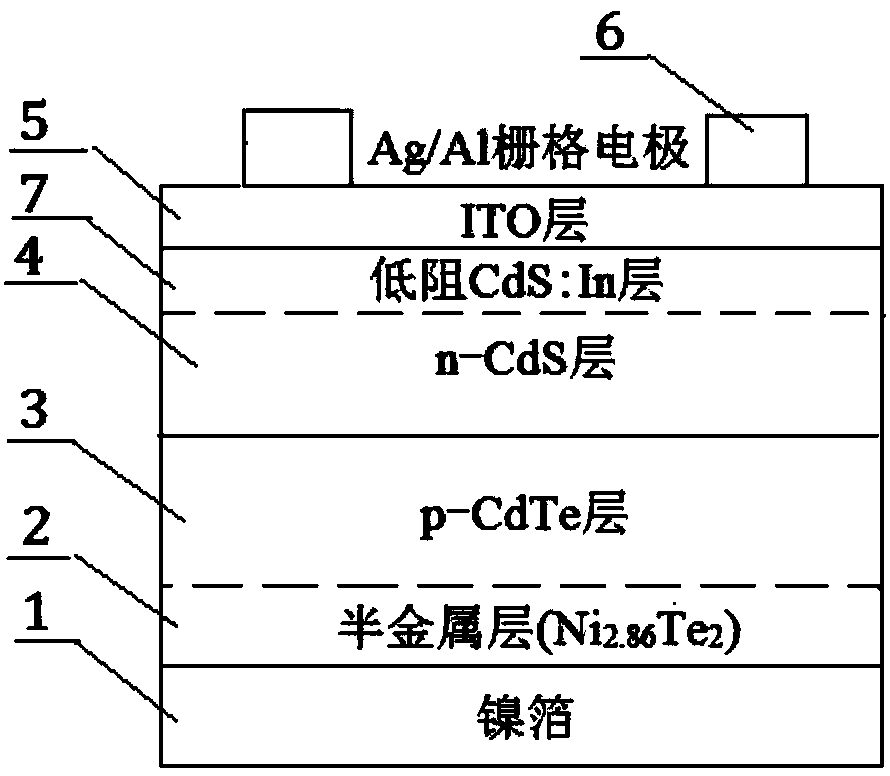

[0042] Example 1 combined figure 1 The structure of the flexible CdTe / CdS thin film solar cell of the present invention is illustrated.

[0043] figure 1 Among them, 1 is a metal back electrode, 2 is a semi-metal layer, 3 is a p-type CdTe layer, 4 is an n-type CdS layer, 5 is a transparent conductive film, 6 is a metal grid electrode, and 7 is a low-resistance CdS:In layer. The metal grid electrode 6 and the metal back electrode 1 are respectively the positive and negative electrodes of the battery.

[0044] Among them, the metal back electrode 1 is a nickel foil with a thickness of 0.1-0.5 mm; the p-type CdTe layer 3 is a gradient tellurium-rich p-type CdTe layer with a thickness of about 1.5-3.5 μm; the thickness of the n-type CdS layer 4 is 0.7-1.2 μm; the transparent conductive film 5 is an indium-doped tin oxide (ITO, namely SnO2:In) film with a thickness of 0.8-1.2 μm; the low-resistance CdS:In layer 7 is formed during the preparation process, from the n-type CdS layer...

Embodiment 2

[0045] Example 2 Preparation of the flexible CdTe / CdS thin film solar cell of the present invention.

[0046] Use commercially available nickel foil with a thickness of 0.3mm and a purity of 99% (the thickness of the nickel foil can be 0.1 to 0.5mm, and the purity is not less than 98%), cut it into a size of 10.5cm×10cm, and pass through acetone and deionized in turn. After ultrasonic cleaning with water for 10 minutes, blow dry with high-purity nitrogen, and set aside; or soak the nickel foil in 3% to 6% dilute hydrochloric acid for 3 to 5 minutes to remove oxides on the surface of the nickel foil, and then wash with deionized water , dried with high-purity nitrogen, and set aside.

[0047] Analytical grade CdSO 4 (0.05M), Na 2 TeO 3 (0.005M), Na 2 SO 4 (0.2M) and NaCl (0.2M) in aqueous solution, with H 2 SO 4 Adjust the pH value to 2, then add CTAB at a ratio of 0.05g / 100mL, and stir the solution at room temperature until a uniform transparent solution without precipi...

Embodiment 3

[0052] Example 3 is an illustration of the preparation conditions of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com