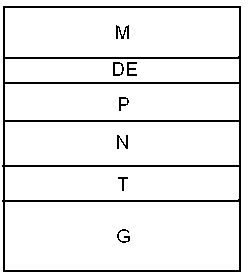

CdTe solar cell and method for manufacturing same

A technology for solar cells and electrode areas, applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency of cadmium telluride solar cells, etc., and achieve the effects of improving photoelectric conversion efficiency, reducing process flow, and improving light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

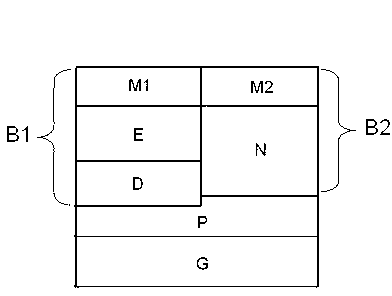

[0057] Specifically, the CdTe solar cell is prepared through the following steps:

[0058] (a) Pretreatment of glass substrate G: use 2.2mm thick ordinary glass as the substrate, first use acetone to ultrasonically clean it for 10 minutes to remove the grease on the glass surface, and then use cleaning agent to ultrasonically clean it for 10 minutes to remove inorganic dirt on the glass surface Then use deionized water to ultrasonically clean for 10 minutes to remove impurities on the glass surface, and finally dry the glass and put it into the pretreatment chamber, and use plasma to clean the glass substrate;

[0059] (b) Production of CdTe thin film P: put the glass substrate on the workpiece rack of vacuum coating equipment, and the evaporation source is high-purity CdTe powder. Vacuum down to 1×10 -3 Pa, enter Ar gas, adjust the flow rate to 10ml / min, adjust the temperature of the sublimation source to 600°C, the temperature of the substrate to 500°C, and coat the film fo...

Embodiment 2

[0065] The difference from Example 1 is that the thickness of the glass substrate G is 3.2 mm.

Embodiment 3

[0067] The difference from Example 1 is that the thickness of the light absorbing layer P is 2um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com