Substrate material for mercury cadmium telluride material growth by liquid phase epitaxy method and preparation thereof

A technology of liquid phase epitaxy and substrate material, which is applied in the directions of liquid phase epitaxy layer growth, single crystal growth, and crystal growth, and can solve the problem of low size, performance and yield of CdZnTe single crystal, poor matching, CdZnTe Substrate difficulties and other issues, to achieve the effect of low cost, uniform composition, and short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] For further illustrating the present invention, specifically set forth in conjunction with the following examples:

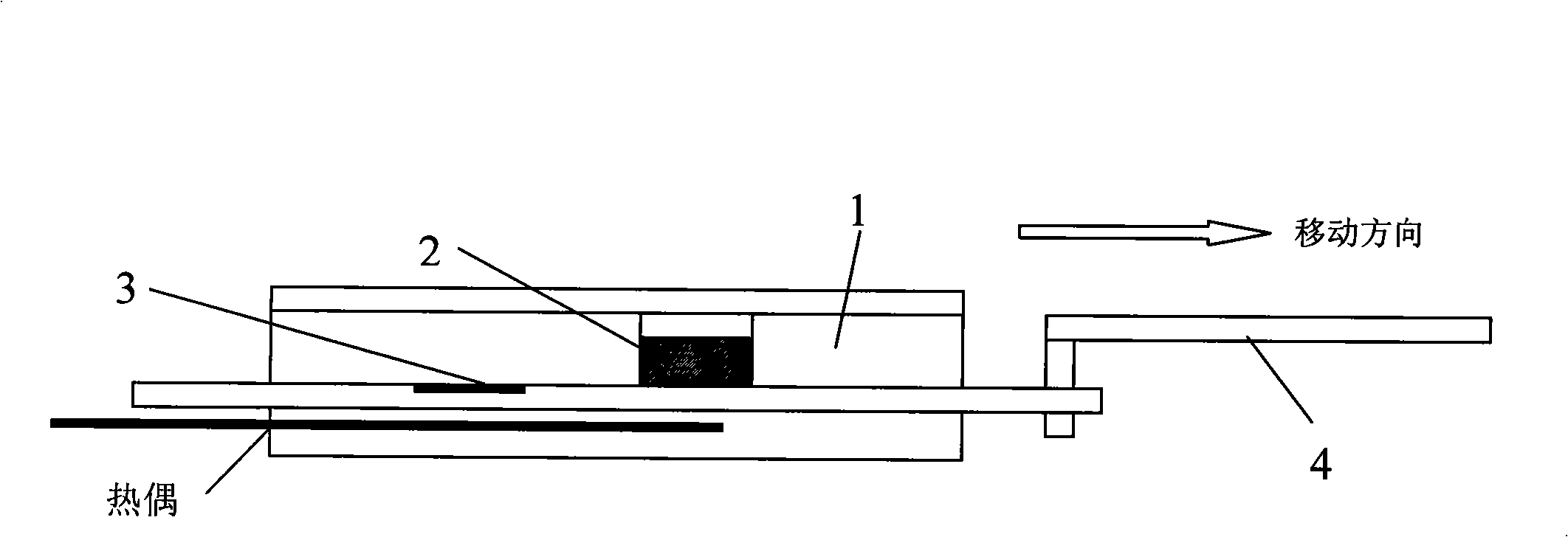

[0023] A substrate material for growing mercury cadmium telluride material by liquid phase epitaxy, which is formed on a cadmium zinc telluride substrate or Si / GaAs / CdTe, Si / CdTe, Ge / GaAs / CdTe, Al 2 o 3 / GaAs / CdTe composite substrate and other conventional substrate materials, and then grow a layer of cadmium zinc telluride single crystal thin film that completely matches the lattice constant of mercury cadmium telluride.

[0024] The liquid phase epitaxial growth method of this material comprises the following steps:

[0025] (1) Preparation of growth solution:

[0026] Using cadmium zinc telluride compound as the liquid phase epitaxial growth solution, in this example, according to the lattice constant of the mercury cadmium telluride crystal thin film with a specific response wavelength, the target value of the solid component of the cadmium zinc tel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com