Self-doped silicon-germanium/silicon multiple quantum well thermosensitive material applied to uncooled infrared detection array

An uncooled infrared, detection array technology, applied in electrical radiation detectors, from chemically reactive gases, single crystal growth, etc., can solve problems such as limiting the development of uncooled infrared detection technology, poor MEMS process compatibility, and production line pollution, etc. Achieve the effect of reducing the difficulty of preparation, increasing the allowable range, and improving the absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

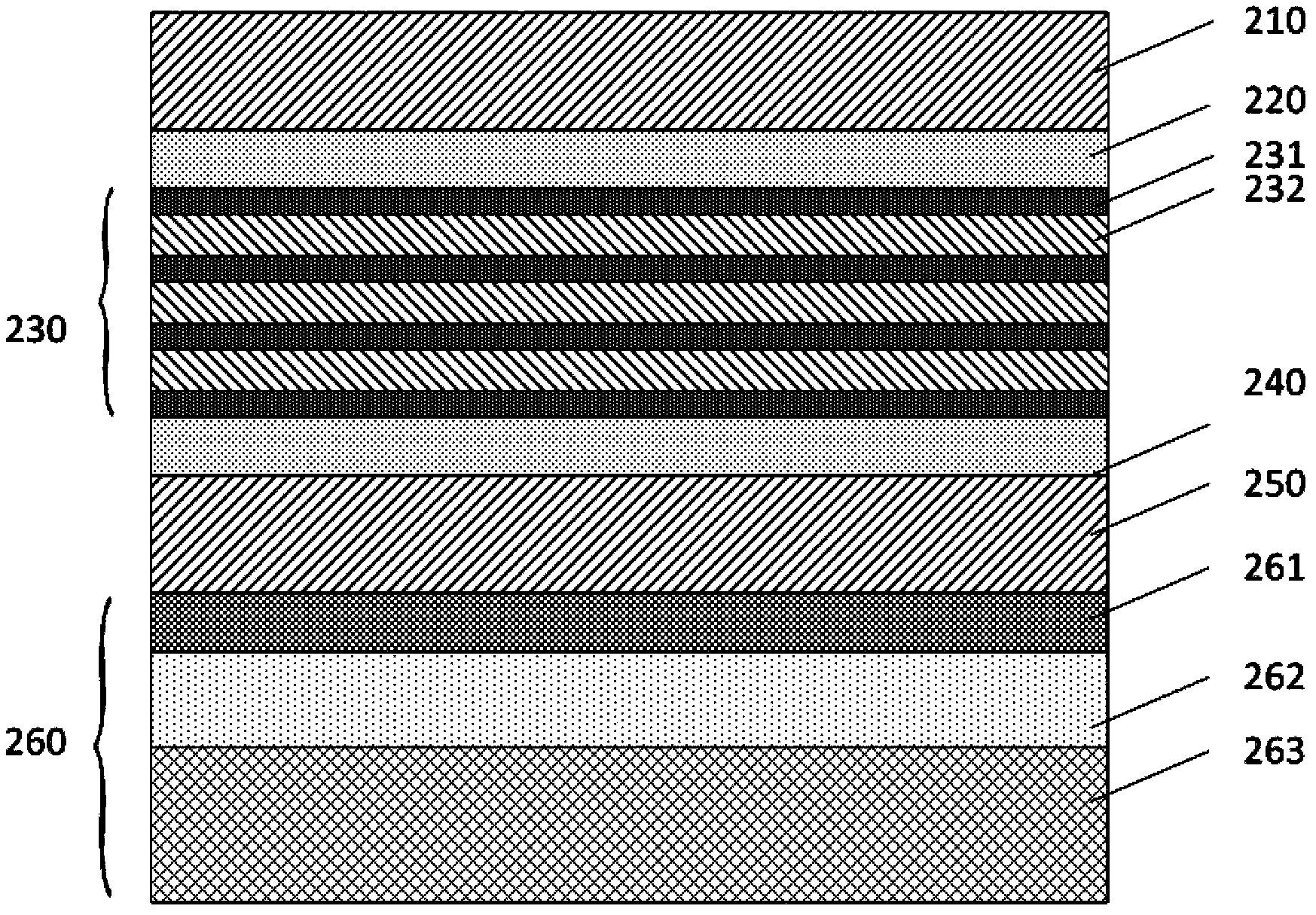

[0053] For the self-doped silicon germanium / silicon multiple quantum well heat-sensitive material used in an uncooled infrared detection array described in the patent of the present invention, when the content of germanium in the silicon germanium layer is 30%, the thickness of the silicon layer 232 (potential barrier) is 30nm, silicon germanium / silicon cycle number is 4 layers; bottom isolation layer 240, top isolation layer 220 is 35nm thick, undoped single crystal silicon; bottom contact layer 250, top contact layer 210 thickness is 150nm, p-type boron doped Heterogeneous single crystal silicon, the doping concentration is 10 19 cm -3 As mentioned above, when the thickness of the single crystal silicon germanium layer 231 in the silicon germanium / silicon multi-quantum well structure 230 is 5nm, 10nm, and 15nm respectively, combined with the position of each energy level and Fermi level in the valence band and the formula (1), the material TCR The corresponding theoretical ...

Embodiment 2

[0055] For the self-doped silicon germanium / silicon multiple quantum well heat-sensitive material used in the uncooled infrared detection array described in the patent of the present invention, when the thickness of the single crystal silicon germanium layer 231 in the silicon germanium / silicon multiple quantum well structure 230 is 10nm , the thickness of the silicon layer 232 (potential barrier) is 30nm, and the silicon germanium / silicon cycle number is 4 layers; the bottom isolation layer 240 and the top isolation layer 220 are 35nm thick, undoped single crystal silicon; the bottom contact layer 250, the top contact Layer 210 has a thickness of 150 nm, p-type boron-doped single crystal silicon, and the doping concentration is 10 19 cm -3 Above, when the contents of germanium in the silicon germanium layer are 25%, 30%, and 35% respectively, combined with the position of each energy level and Fermi energy level in the valence band and the formula (1), the theoretical value o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com