Epitaxial structure of gallium nitride device

An epitaxial structure, gallium nitride technology, applied in the field of microelectronics, can solve problems such as poor lattice quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

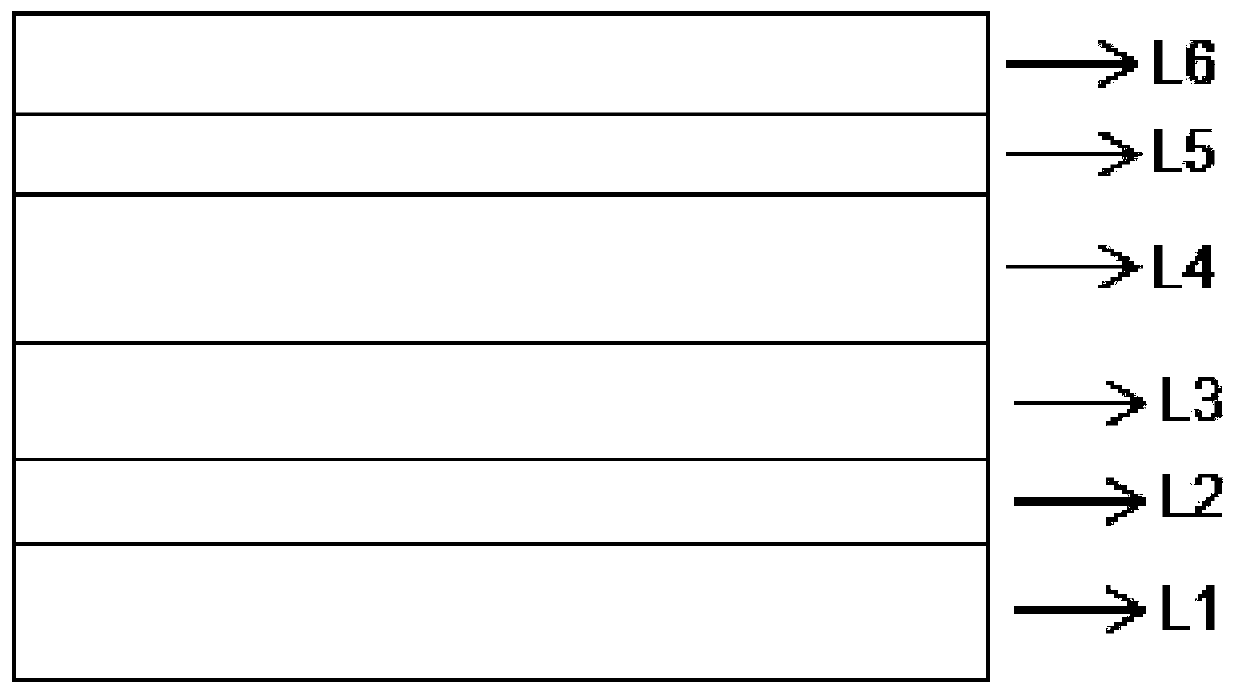

[0018] 1. Provide substrate L1, which is all materials used for epitaxial gallium nitride thin film, including insulating or semi-insulating sapphire, silicon, silicon carbide, gallium nitride and diamond, with a size range of 2-8 inches.

[0019] 2. The nucleation layer L2 is grown at a temperature between 400-700° C., which can be any one or combination of ALN, ALGaN, and GAN, and its total thickness is 10-50 nm.

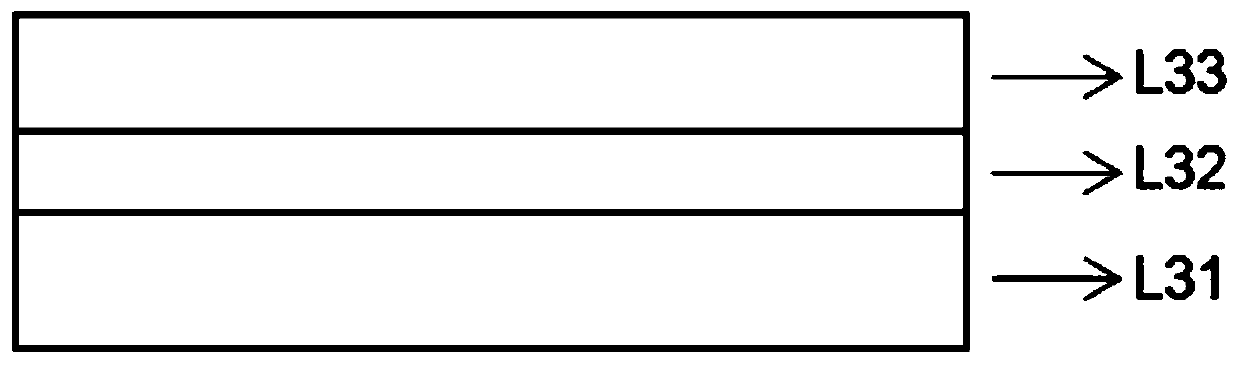

[0020] 3. Growing the buffer layer L3 on the nucleation layer, the growth temperature is between 1050-1130°C. is a cyclic growth pattern composed of three sublayers. It includes the first sub-layer crystal nucleus layer GaN1L31 with a thickness of 20nm, and the total amount of NH3 in the growth environment is 10L / min, which mainly provides crystal nucleus for the subsequent leveling layer. The networked SiNL32 layer is grown on the second sub-layer crystal nucleus layer GaN1L32, its main characteristic is a uniform network structure, which will provide a uniform ...

Embodiment 2

[0025] 1. Provide substrate L1, which is all materials used for epitaxial gallium nitride thin film, including insulating or semi-insulating sapphire, silicon, silicon carbide, gallium nitride and diamond, with a size range of 2-8 inches.

[0026] 2. The nucleation layer L2 is grown at a temperature between 400-700° C., which can be any one or combination of ALN, ALGaN, and GAN, and its total thickness is 10-50 nm.

[0027] 3. Growing the buffer layer L3 on the nucleation layer, the growth temperature is between 1050-1130°C. is a cyclic growth pattern composed of three sublayers. It includes the first sub-layer crystal nucleus layer GaN1L31 with a thickness of 20nm, and the total amount of NH3 in the growth environment is 30L / min, which mainly provides crystal nucleus for the subsequent leveling layer. The networked SiNL32 layer is grown on the second sub-layer crystal nucleus layer GaN1L32, its main characteristic is a uniform network structure, which will provide a uniform ...

Embodiment 3

[0032] 1. Provide substrate L1, which is all materials used for epitaxial gallium nitride thin film, including insulating or semi-insulating sapphire, silicon, silicon carbide, gallium nitride and diamond, with a size range of 2-8 inches.

[0033] 2. The nucleation layer L2 is grown at a temperature between 400-700° C., which can be any one or combination of ALN, ALGaN, and GAN, and its total thickness is 10-50 nm.

[0034] 3. Growing the buffer layer L3 on the nucleation layer, the growth temperature is between 1050-1130°C. is a cyclic growth pattern composed of three sublayers. It includes the first sub-layer crystal nucleus layer GaN1L31 with a thickness of 20nm, and the total amount of NH3 in the growth environment is 50L / min, which mainly provides crystal nucleus for the subsequent leveling layer. The networked SiNL32 layer is grown on the second sub-layer crystal nucleus layer GaN1L32, its main characteristic is a uniform network structure, which will provide a uniform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com