Method and device for growing cadmium zinc telluride crystals in mobile tellurium solvent melting zone

A melting zone method, cadmium zinc telluride technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of close to equal concentration, difficult to achieve, reduce μτ, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The cadmium zinc telluride crystal growth of the present invention is realized by moving the Te solvent melting zone method and its special equipment.

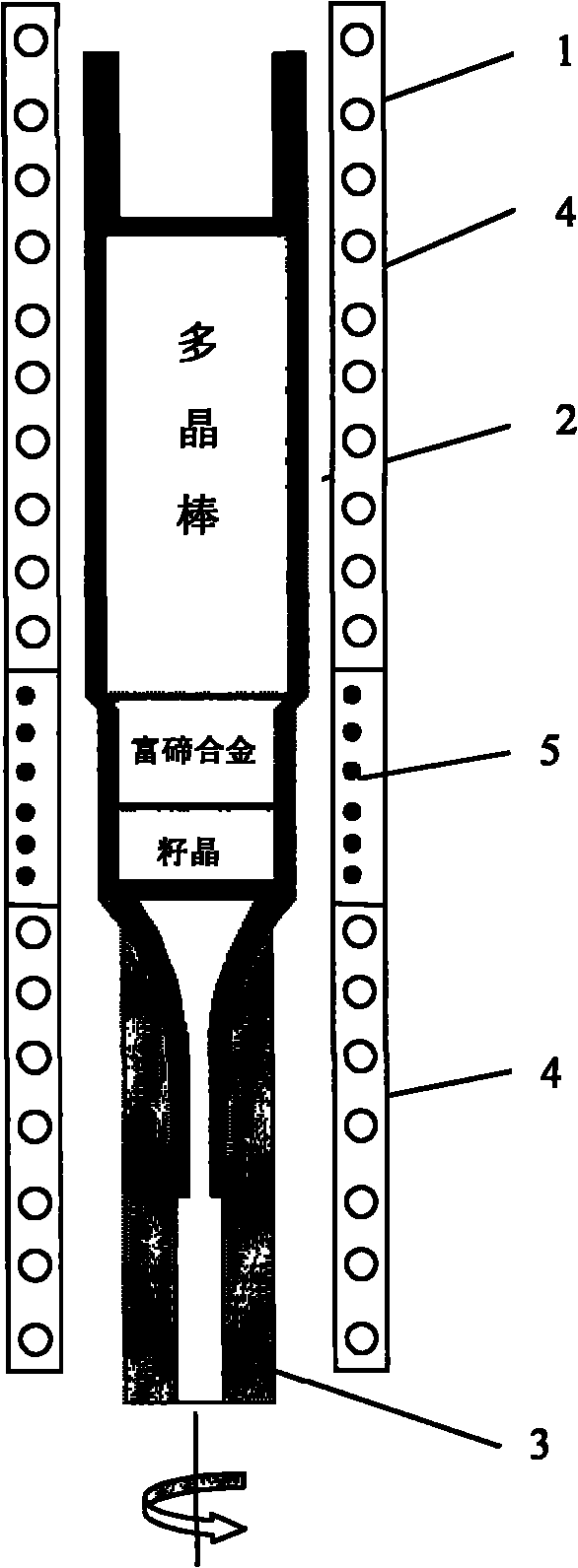

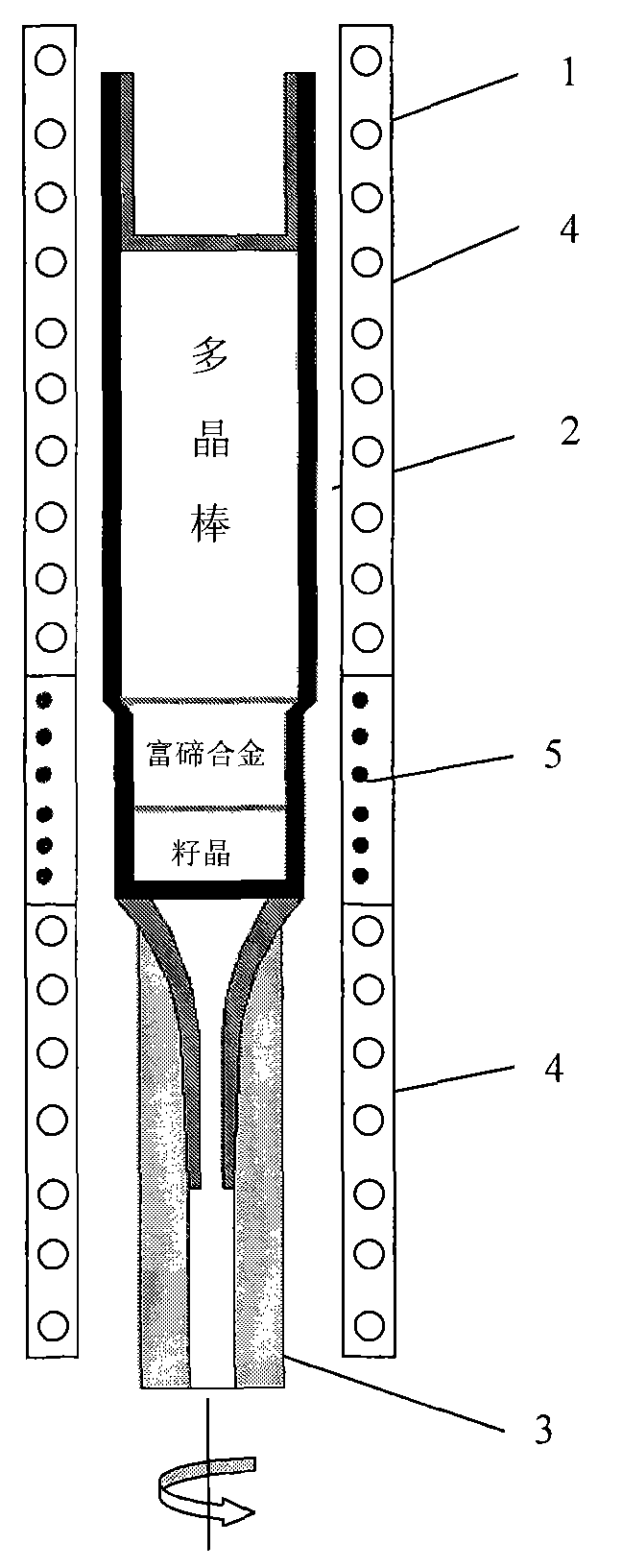

[0017] see figure 1 , the crystal growth device used in the present invention comprises a body of furnace 1, a long crystal tube 2, and a rotatable support rod 3: wherein the body of furnace 1 is composed of resistance heaters 4 at both ends and a high-frequency electromagnetic induction heater 5 in the middle; Put the seed crystal, Te-rich alloy, and polycrystalline rod into the long crystal tube in the order of 2 vacuumize and seal; the long crystal tube 2 is placed on the matching rotatable support rod 3 to ensure that the long crystal tube 2 is in a vertical and stable state; furnace The body 1 is located at the periphery of the long transistor 2, and the furnace body is vertically adjustable. The Te-rich alloy area is located at the high-frequency electromagnetic induction heater 5; when the growth s...

Embodiment 2

[0024] Embodiment 2: In this embodiment, the same growth device as in Embodiment 1 above is used.

[0025] The growth process steps in this embodiment are completely the same as those in the first embodiment above, except that some process parameters are changed. The different process parameters are: (1) the Te-rich amount in the Te-rich alloy is 65% by mass; (2) the temperature of the high-frequency electromagnetic induction heater is set to 872°C during growth. CdZnTe crystals are finally obtained.

Embodiment 3

[0026] Embodiment 3: In this embodiment, the same growth device as in Embodiment 1 above is used.

[0027] The growth process steps in this embodiment are completely the same as those in the first embodiment above, except that some process parameters are changed. The different process parameters are: the rising speed of the furnace body 1 is set to 0.04mm / h. CdZnTe crystals are finally obtained.

[0028] The device and method for growing cadmium zinc telluride crystals by adopting the tellurium solvent melting zone method of the present invention are simple to operate, reduce the crystal growth temperature, reduce the pollution of impurities, and at the same time, the existence of the process of zone melting can purify the crystals, and finally High-purity cadmium zinc telluride crystals are obtained, which fully meet the requirements as detector materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com