A long collagen fiber with natural structure and its preparation method and application

A long fiber and collagen technology, applied in the field of biomedical materials, can solve the problems of insufficient mechanical strength, loss of biological properties, fast metabolism, etc., and achieve excellent mechanical properties, conducive to repair, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Slowly drip the PEG4000 solution into the type I collagen solution (pH=2) with a certain concentration extracted from cowhide under ice-water bath conditions and mix evenly, adjust the pH of the spinning solution to 3.8-4.5 with NaOH, and the collagen solution The final concentration is 10 mg / mL, the mass fraction of PEG4000 is 3.25%, and the spinning solution is obtained by centrifuging and defoaming at low temperature (0-4° C.).

[0075] PEG20000, TES, NaCl, Na 2 HPO 4 2H 2 O, NaH 2 PO 4 Dissolve in water and mix evenly. The concentration of each substance in the solution is: PEG20000 with a mass volume fraction of 10%, 6.8mg / mL TES, 7.8mg / mL NaCl, 4.1mg / mLNa 2 HPO 4 2H 2 O and 12.1 mg / mL NaH 2 PO 4 , adjust its pH to 8 with NaOH to obtain an aqueous coagulation bath.

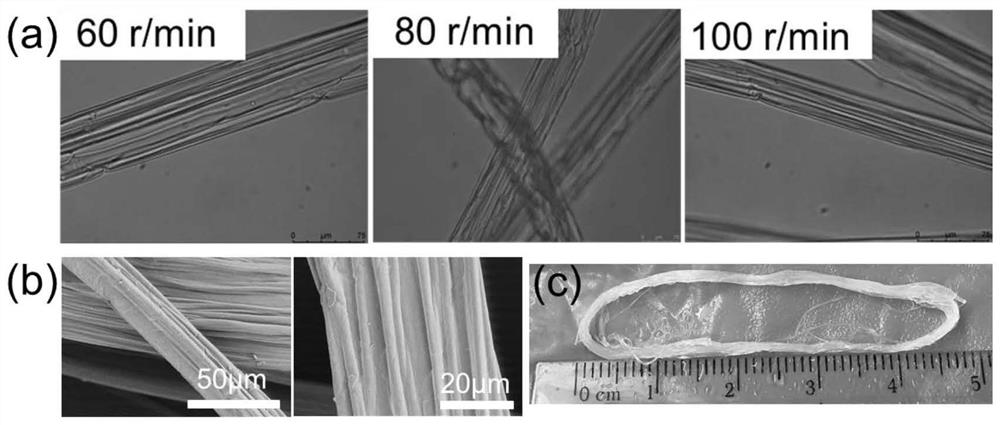

[0076] Heat the aqueous phase coagulation bath to 37°C, add the spinning solution into the syringe pump, the needle specification of the syringe pump is 23G (inner diameter D=0.33mm), push the...

Embodiment 2

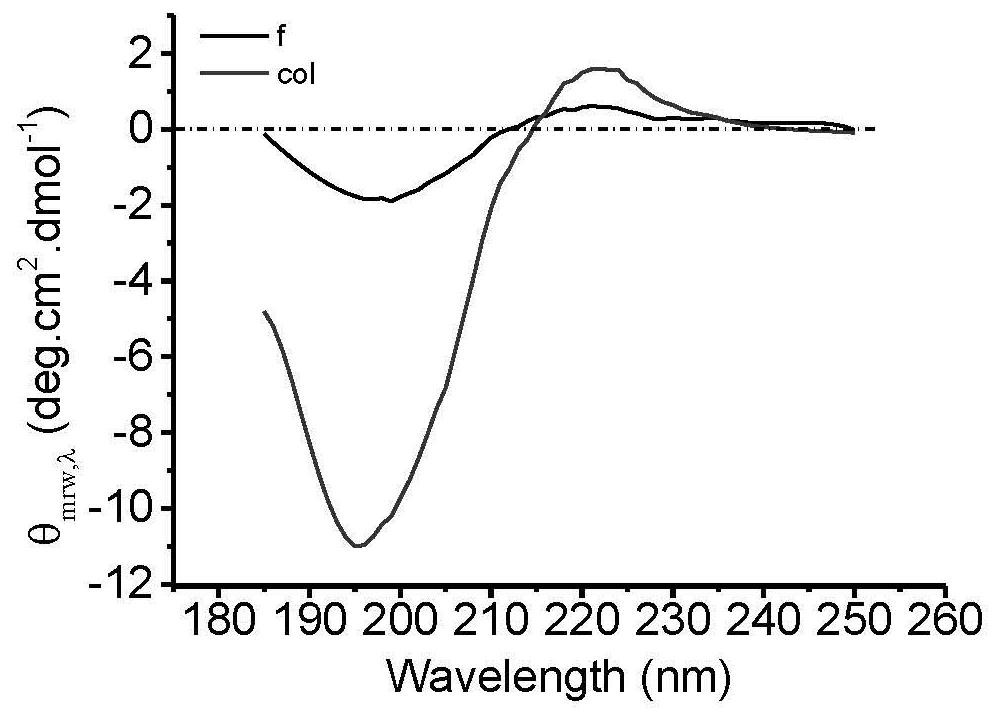

[0079] Freeze-dry the collagen fibers and 10mg / mL collagen solution prepared under the rotating speed of 60r / min in Example 1, then weigh 1mg and dissolve them in 10mL 20mM HCl solution, and scan with a circular dichroism spectrometer after completely dissolving , see the result image 3 .

[0080] From image 3 The results showed that the collagen fibers and collagen solution prepared under this condition had two characteristic peaks in the wavelength range of 190-260nm, which were positive absorption peak at 221nm and negative absorption peak at 197nm. Although the intensity of the positive and negative absorption peaks of the collagen fibers decreased, the positions of the peaks hardly moved, which indicated that the collagen fibers prepared by this method could maintain their own secondary structure.

Embodiment 3

[0081] Example 3 In vitro culture of bone marrow mesenchymal stem cells

[0082] (1) Wet spinning 10mg / mL collagen spinning solution, the injection speed is 0.2min / mL, the needle size is 23G (inner diameter d=0.33mm) and the collection speed is 60r / min to prepare uniform size Orientation of collagen fibers. The collagen fibers were further post-treated, and the collagen fibers were chemically cross-linked with 50 mM EDC and 25 mM NHS as cross-linking agents, and then fully washed.

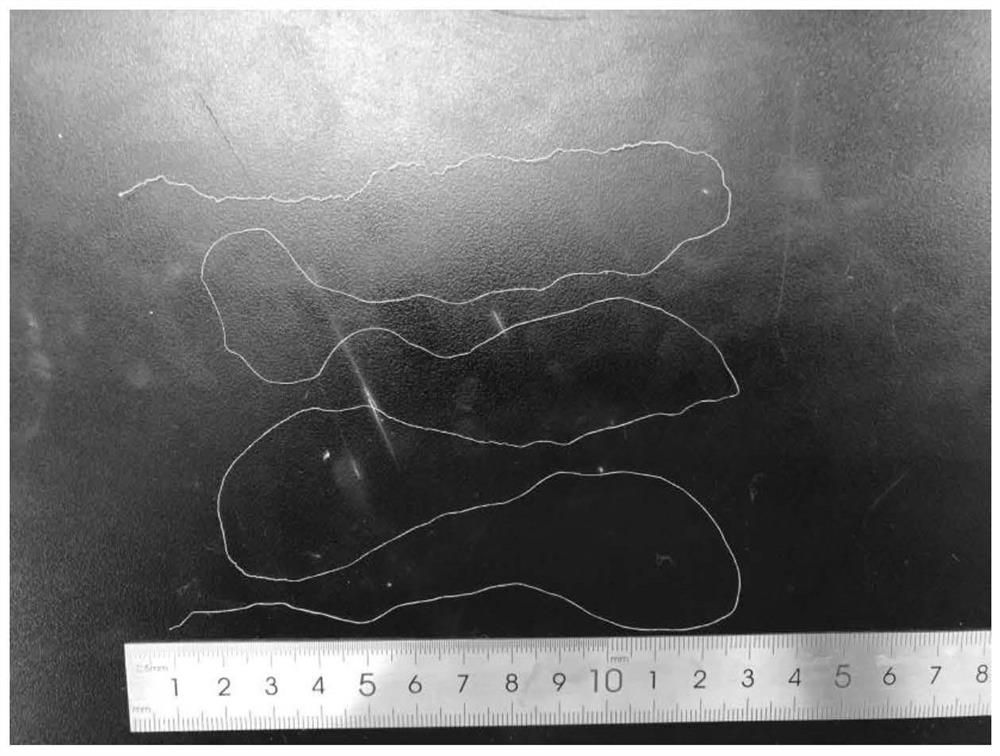

[0083] (2) Taking conventional massive collagen hydrogel with disordered structure as the control group, prepare massive collagen hydrogel according to the same method in (1), that is, drop the same spinning solution into the coagulation bath to prepare massive collagen hydrogel, and use the same method to modify the bulk hydrogel.

[0084] (3) Before inoculating the cells, the oriented collagen fibers and block collagen hydrogel were soaked overnight in 75% ethanol and washed with sterile PBS so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com