Dust settling system of bucket wheel machine of coal yard in thermal power plant as well as dust settling method for the system

A technology for a thermal power plant and a bucket turbine, which is applied to a dust reduction system of a bucket turbine in a coal yard of a thermal power plant and its dust reduction field, can solve problems such as dust pollution in the coal yard, and achieve the effect of obvious dust removal effect, dust reduction, and improvement of residents' living environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

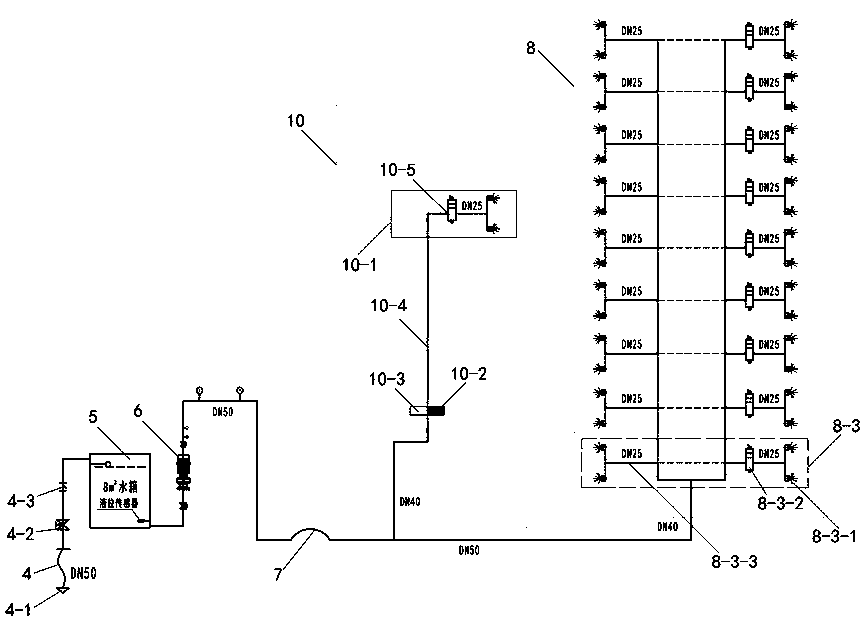

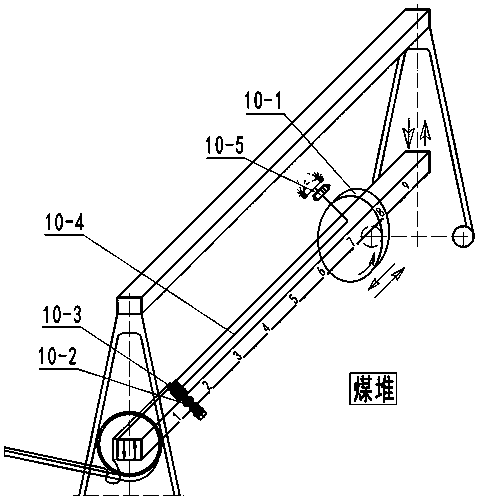

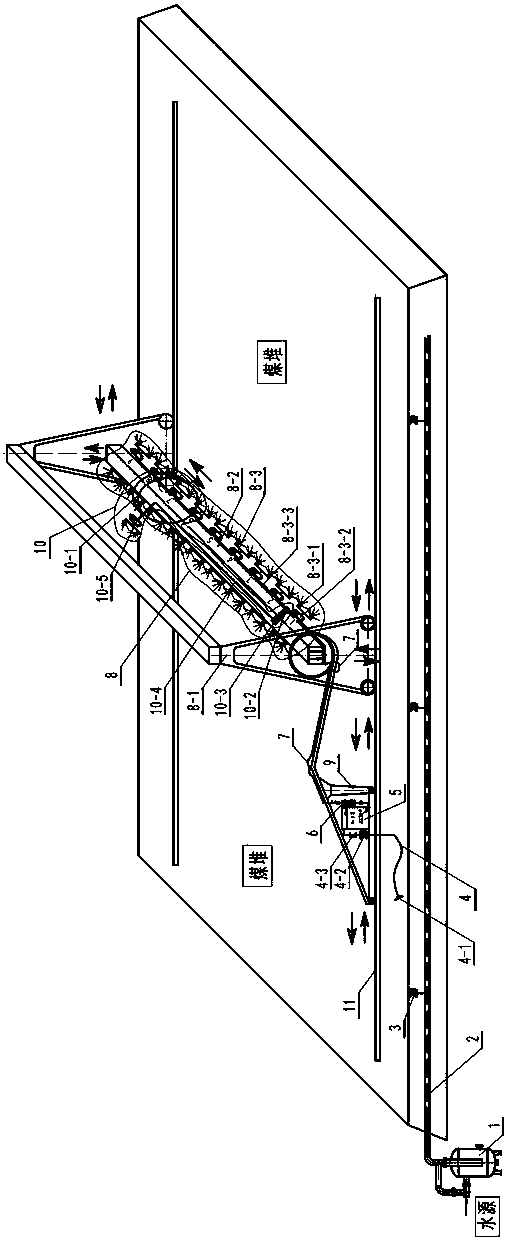

[0032] attached by figure 1Shown: a coal yard bucket turbine dust suppression system in a thermal power plant, the system includes a cyclone decontamination device 1 connected to the water source, a water supply pipeline 2 connecting the water source and the cyclone decontamination device 1, at least one set on the water supply pipeline 2 Three cut-off valves 3, the first hose 4 used to connect the cut-off valve 3 on the water supply pipeline 2, the automatic water tank 5 connected to the hose 4, the water pump 6 with frequency conversion and voltage stabilization function connected to the automatic water tank 5, connected to the water pump 6 The second hose 7 at the other end, the coal pile sprinkler 8 connected to the second hose 7, the bucket wheel trailer 9 for setting the automatic water tank 5 and the second hose 7, and the bucket wheel movable beam The coal spraying device 10 on the top; the coal pile spraying device 8 is composed of a bucket wheel machine frame main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com