Fully-mechanized top-coal caving face initial-mining-stage goaf fire prevention and extinguishment method

A technology for fully mechanized caving face and goaf, which is applied in the directions of fire prevention, dust prevention, mining equipment, etc., can solve the problems of slow advancement of the working face of the safety system, increase the hidden danger of spontaneous combustion and ignition in the goaf, etc., and achieve equipment installation. Convenience, prevention of spontaneous ignition, slow advancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

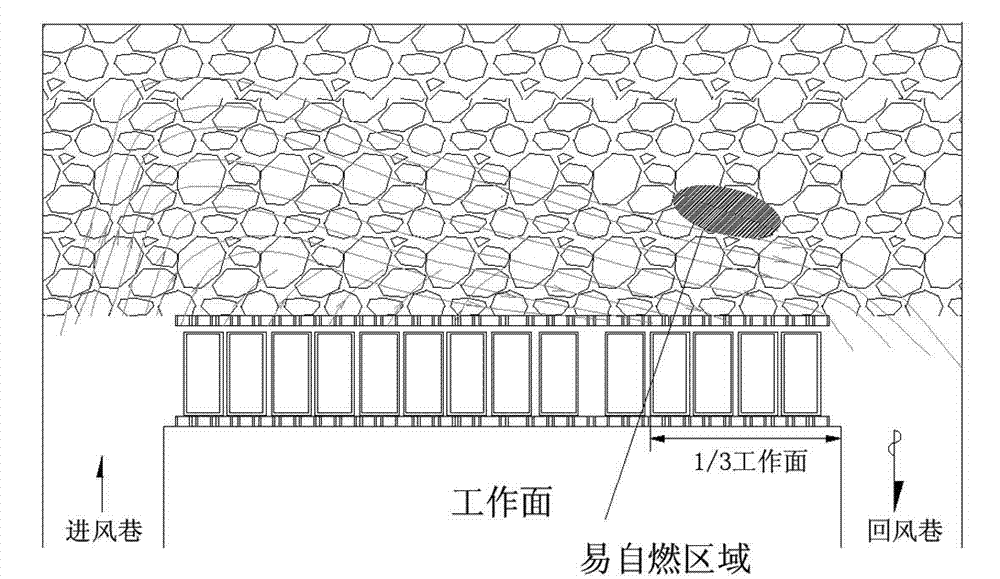

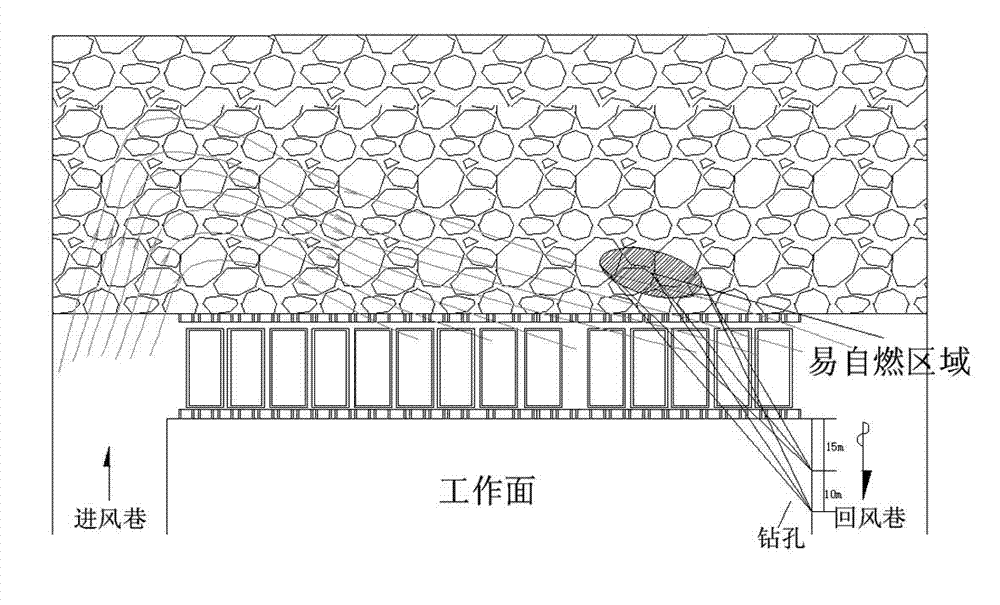

[0018] A method for preventing and extinguishing fire in the goaf of the fully mechanized caving face in the initial mining period described in the present invention is to first determine the areas prone to spontaneous combustion in the goaf of the fully mechanized caving face, and then adopt fire prevention measures,

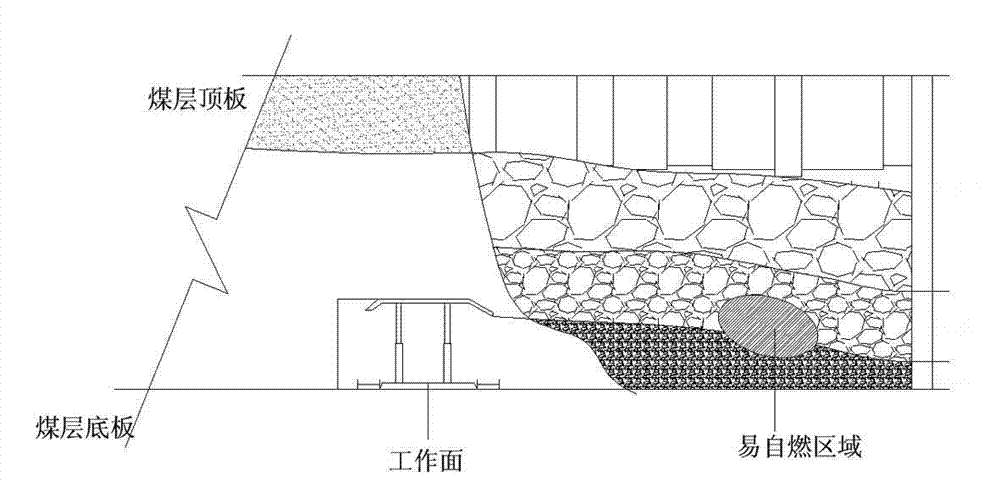

[0019] The area prone to spontaneous combustion in the goaf of the fully mechanized caving face is determined by the division method of three horizontal zones and three vertical zones. area; in the vertical direction, the junction of the middle and lower caving layers is an area prone to spontaneous combustion;

[0020] The anti-fire measures adopted are steam mist resistance spray and target pouring;

[0021] The steam mist resistance spray is to spray the resistance agent from the end of the working face. The resistance agent enters the goaf with the wind flow and covers the surface of the floating coal. The resistance agent is mainly composed of magnesium ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com