Flame retardant magnesium alloy with excellent mechanical properties, and preparation method thereof

A magnesium alloy, inevitable technology, applied in the field of magnesium alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

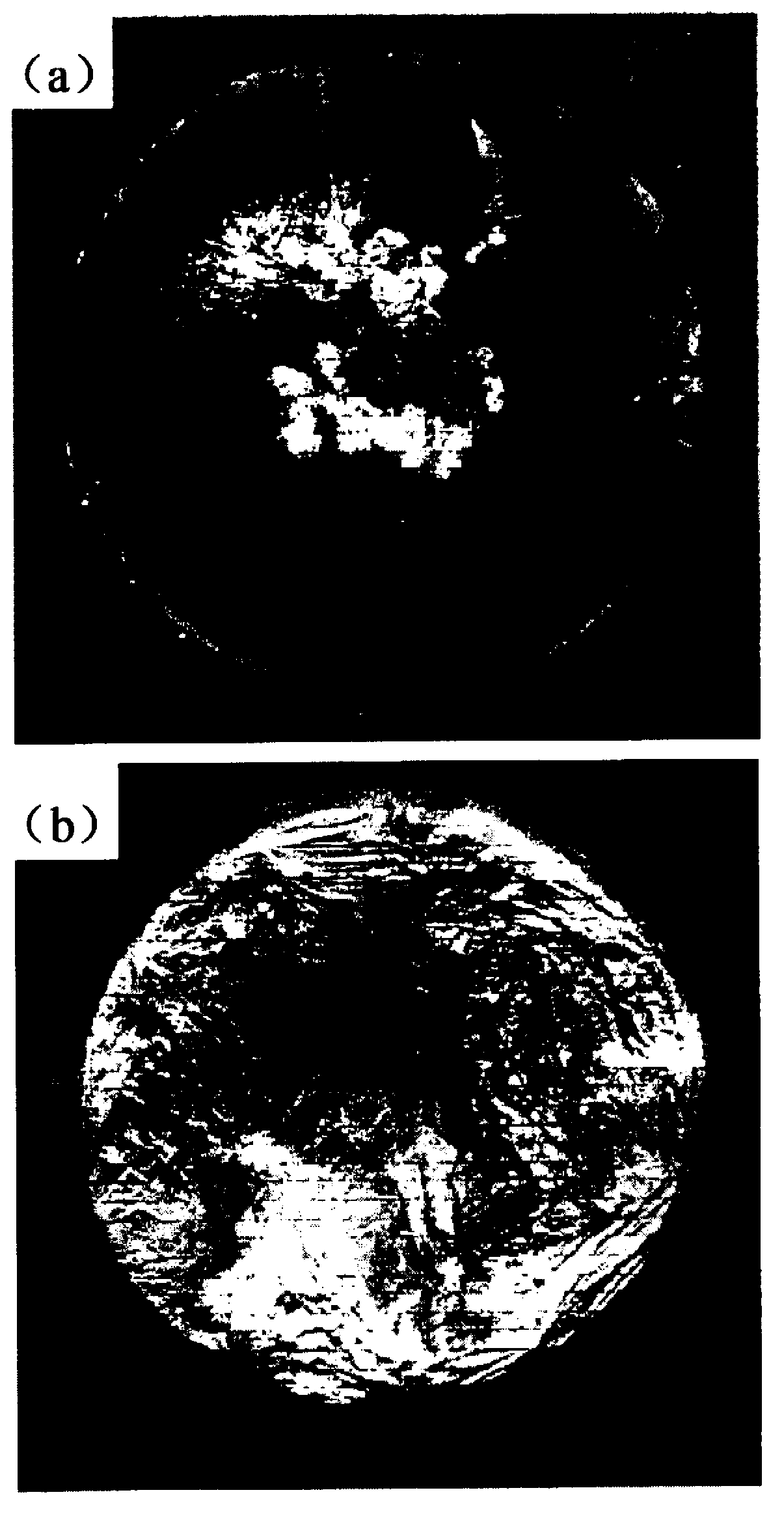

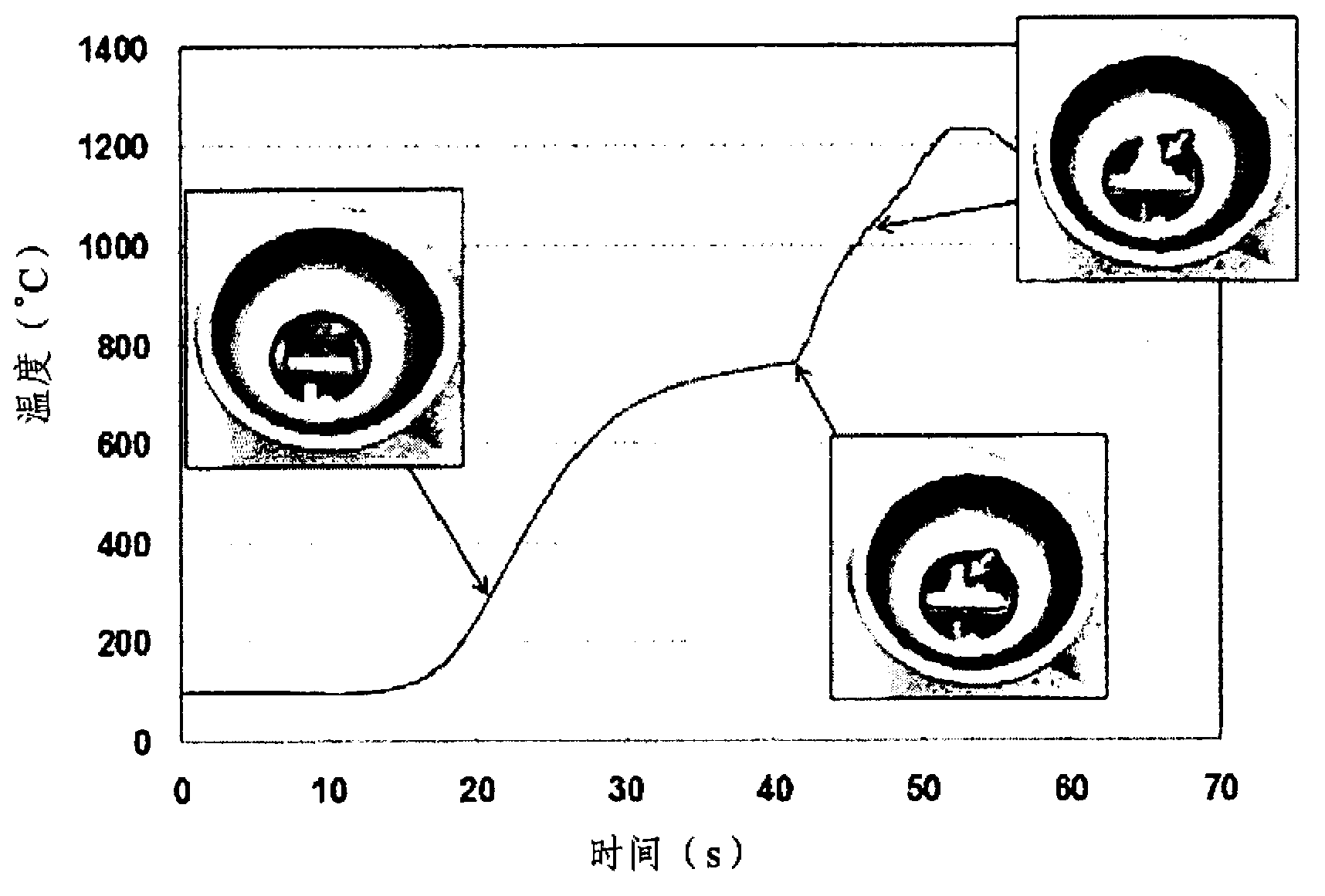

Image

Examples

Embodiment Construction

[0073] Exemplary embodiments of the Mg alloy and its manufacturing method of the present invention will be described in detail below. However, it is to be understood that the embodiments described below are illustrative and do not limit the present invention.

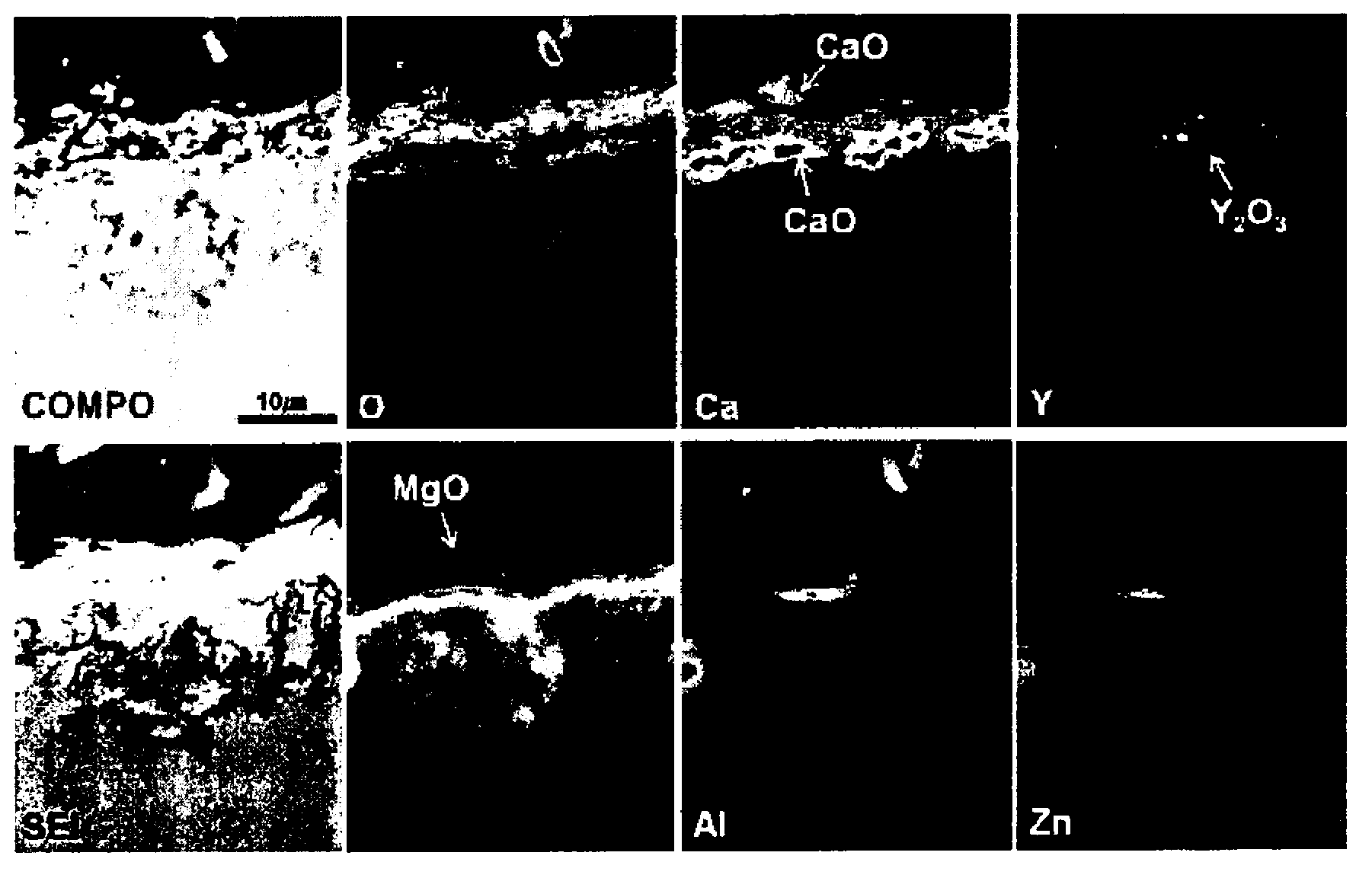

[0074] In order to solve the above-mentioned problems in the related field and achieve the object of the present invention, studies were carried out on the design of alloys by thermodynamic calculations. As a result of this study, the inventors of the present invention found that (as shown in Table 1 below), compared with adding Ca alone When Ca and Y are added in combination to Mg-Al-based alloys or Mg-Al-Zn-based alloys, the fraction of the hard eutectic phase (eutectic phase I) is significantly reduced, while induced Al 2 Formation of the Y phase (i.e., particles forming micronized fines), thereby enabling improved ignition resistance as well as tensile strength.

[0075] Table 1

[0076]

[0077] The inventors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com