Protective layer coating for cold wave printing film as well as preparation method and use method of protective layer coating

A technology of cold stamping film and protective layer, applied in the field of coatings, can solve problems such as high cost and poor environmental protection, and achieve the effects of high added value, uniform and fine coating film surface, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

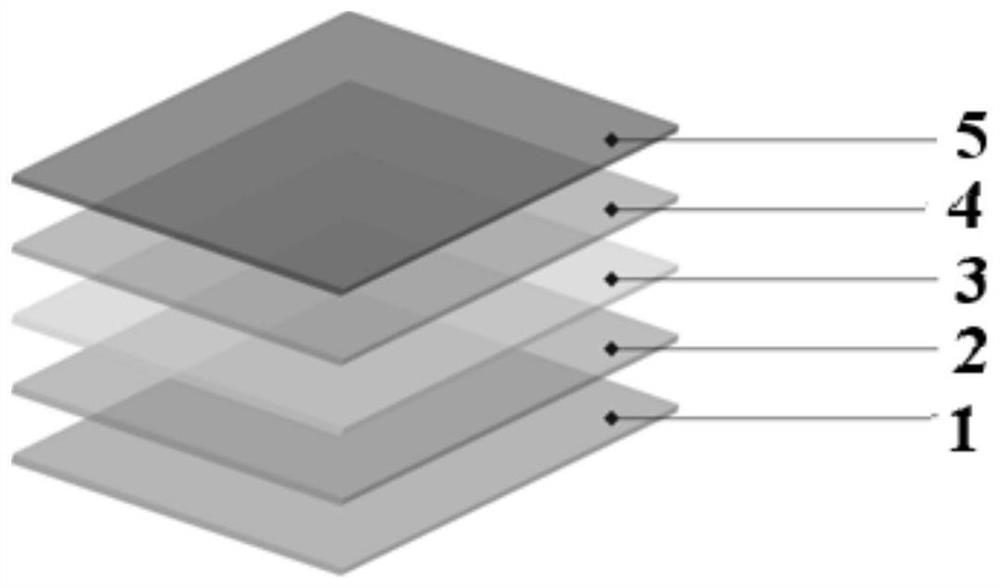

Image

Examples

Embodiment 1

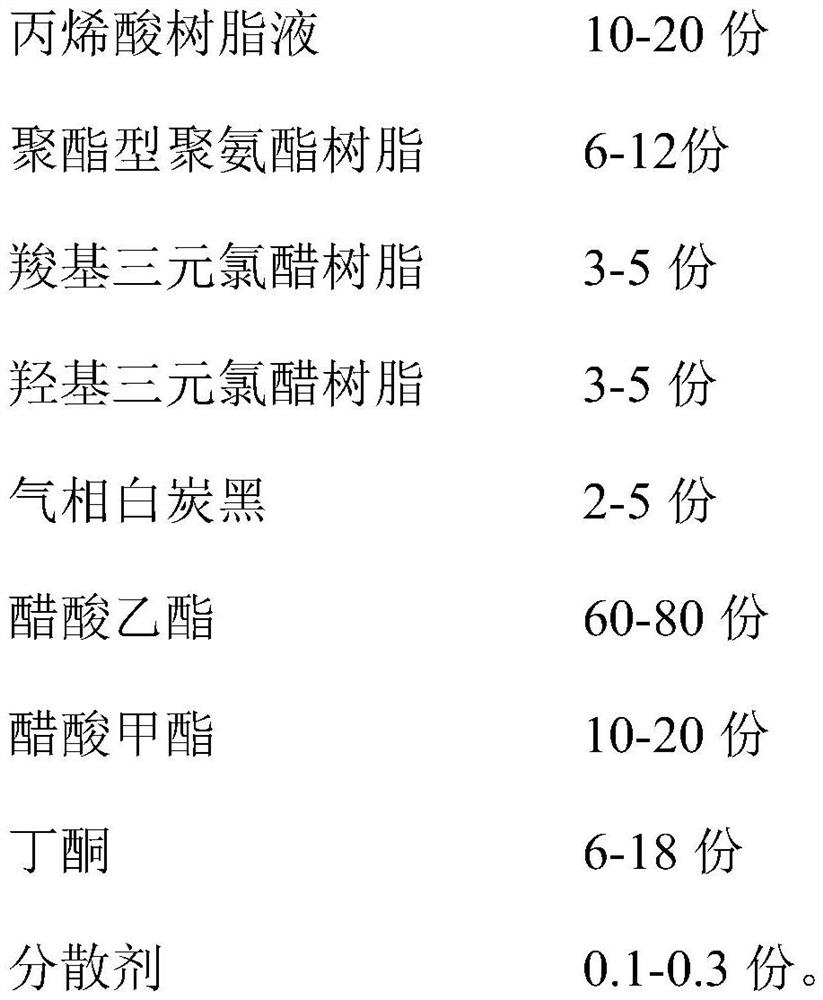

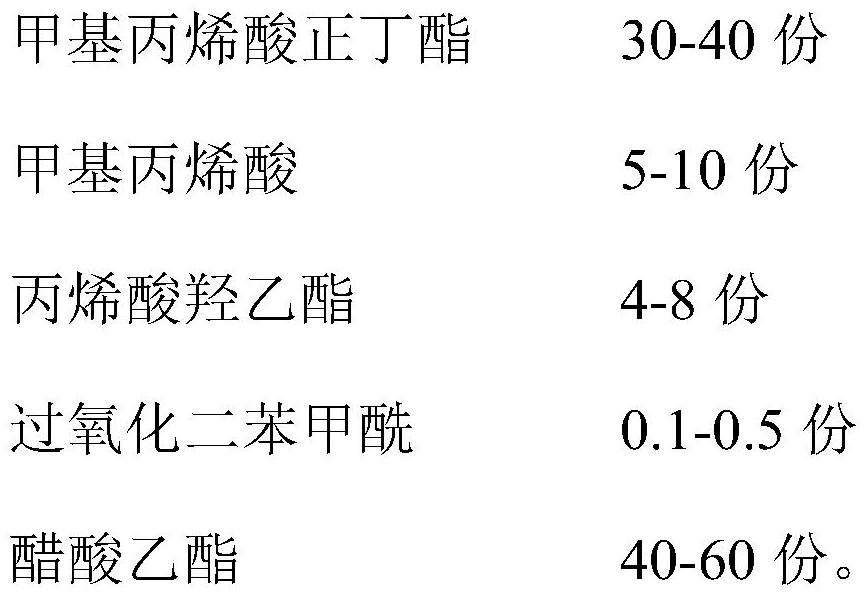

[0057] The protective layer coating for cold stamping film of the present embodiment, by weight, the preparation raw materials comprise the following components:

[0058]

[0059]

[0060] Among them, the polyester type polyurethane resin is selected from Lubrizol polyester type polyurethane resin TPU5713, the carboxyl content of the carboxyl tri-vinyl chloride resin is 2%, the hydroxyl content of the hydroxyl tri-vinyl chloride resin is 2.2%, and the ratio of fumed silica Surface area is 100m 2 / g, the particle size is 12nm, and the dispersant is an acrylate dispersant.

[0061] The preparation method of the protective coating for the cold stamping film of the present embodiment may further comprise the steps:

[0062] 1) preparing acrylic resin liquid;

[0063] 2) Prepare coating mother liquor: by weight, take step 1) 16 parts of acrylic resin liquids, 8 parts of polyester polyurethane resins, 4.5 parts of carboxyl tribasic vinyl chloride resins, 4.5 parts of hydroxy...

Embodiment 2

[0074] The protective layer coating for cold stamping film of the present embodiment, by weight, the preparation raw materials comprise the following components:

[0075]

[0076] Among them, the polyester polyurethane resin is selected from Lubrizol polyester polyurethane resin TPU5713, the carboxyl content of the carboxyl three-component vinyl chloride resin is 3%, the hydroxyl content of the hydroxyl three-component vinyl chloride resin is 2%, and the ratio of fumed silica Surface area is 120-150m 2 / g, the particle size is 12-25nm, and the dispersant is acrylate dispersant.

[0077] The preparation method of the protective coating for the cold stamping film of the present embodiment may further comprise the steps:

[0078] 1) preparing acrylic resin liquid;

[0079] 2) Prepare coating mother liquor: by weight, take step 1) 16 parts of acrylic resin liquids, 10 parts of polyester polyurethane resins, 3 parts of carboxyl tribasic vinyl chloride resins, 3 parts of hydrox...

Embodiment 3

[0090] The protective layer coating for cold stamping film of the present embodiment, by weight, the preparation raw materials comprise the following components:

[0091]

[0092] Among them, the polyester type polyurethane resin is selected from Lubrizol polyester type polyurethane resin TPU5712, the carboxyl content of the carboxyl tri-vinyl chloride resin is 3%, the hydroxyl content of the hydroxyl tri-vinyl chloride resin is 2%, and the ratio of fumed silica Surface area is 120-150m 2 / g, the particle size is 12-25nm, and the dispersant is a phosphate salt type polymer dispersant.

[0093] The preparation method of the protective layer coating for cold stamping film of the present embodiment, the preparation raw material comprises the following steps:

[0094] 1) preparing acrylic resin liquid;

[0095] 2) Prepare coating mother liquor: by weight, take step 1) 14 parts of acrylic resin liquids, 6 parts of polyester polyurethane resins, 4 parts of carboxyl tribasic vin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com