Glass substrate, liquid crystal display device and method for manufacturing glass substrate

A technology of liquid crystal display devices and glass substrates, which is applied in the direction of transistors, static indicators, optics, etc., can solve the problems of large thickness of liquid crystal display devices, achieve excellent matching effects, reduce production costs, and reduce thickness and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

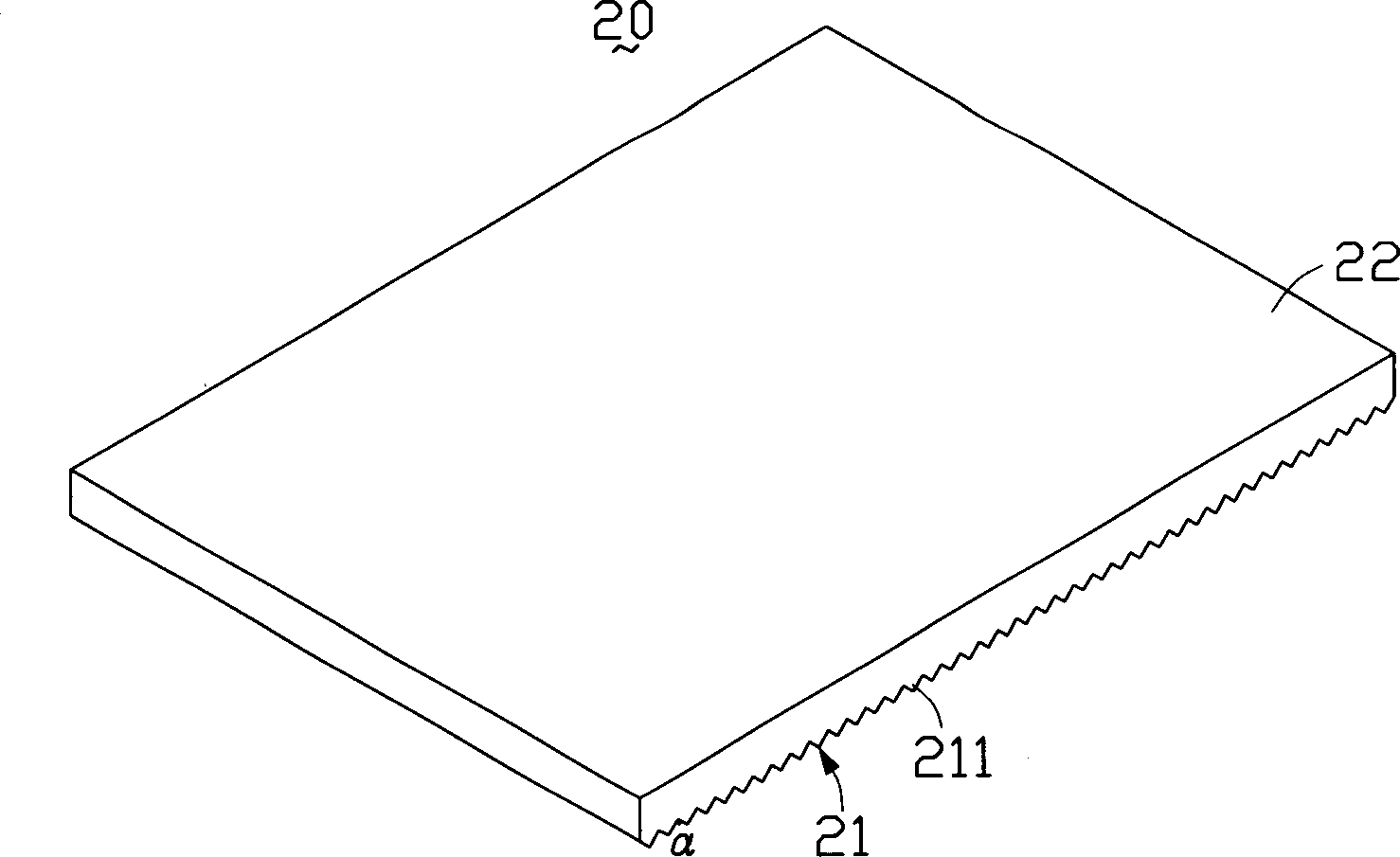

[0021] see figure 2 , is a schematic plan view of the first embodiment of the glass substrate of the present invention. The glass substrate 20 includes a bottom surface 21 and a surface 22 opposite to the bottom surface 21 , the bottom surface 21 has a prism array 211 , and the apex angle α of the prism array 221 is 90 degrees.

[0022] In the present invention, the prism array 211 is directly formed on the bottom surface 21 of the glass substrate 20, so its weight is relatively light. In the backlight module of the prior art, after the light exits through the light guide plate, its angle of view is deflected to one side. After the light is diffused by the diffusion sheet, the light is concentrated by one or two prism sheets, and then the angle of view of the liquid crystal display panel is adjusted. Do collocation, usually its collocation effect is poor. After the glass substrate 20 of the present invention makes the light incident from the bottom surface 21 of the glass s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com