A357 aluminum alloy material containing alterant Sr and Ti and preparation method thereof

A technology of aluminum alloy materials and modifiers, which is applied in the field of A357 aluminum alloy materials and its preparation, can solve the problems of weakening the effect of Sr modification, and achieve the effect of reducing heterogeneous nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

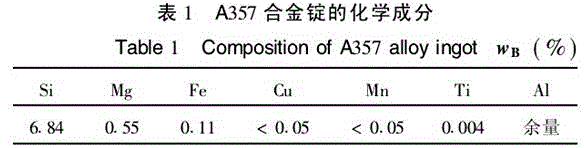

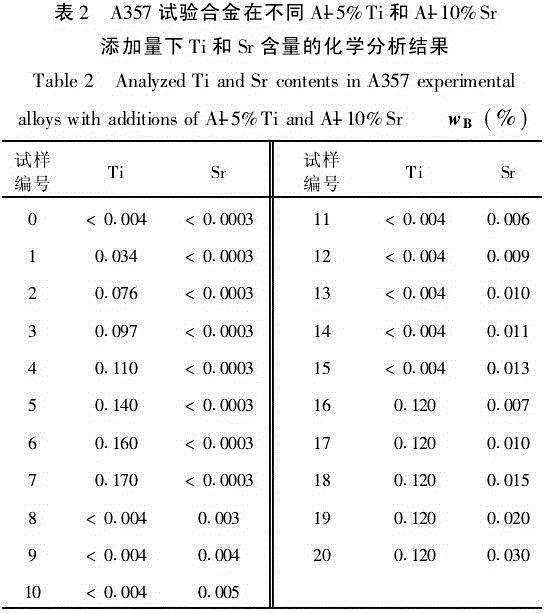

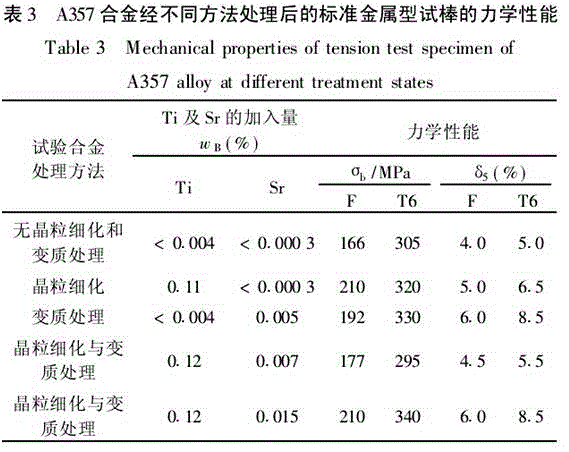

[0007] The alloy used in the test is A357 alloy prefabricated ingot, and its chemical composition is shown in Table 1. A graphite crucible was used to heat and melt the A357 alloy prefabricated ingot in an 8kW resistance furnace. During the grain refinement treatment, the alloy ingot is heated and melted, and then the Al-5%Ti master alloy is added, refined and degassed when the temperature is raised to 740 degrees, and poured after standing. During metamorphic treatment, degassing is carried out twice. The alloy ingot is heated and melted and the temperature is raised to 740 degrees for the first refining degassing. After adding Al-10%Sr master alloy, the temperature is raised to 740e for the second refining degassing. After standing pouring. When grain refinement and modification are carried out at the same time, degassing is performed twice. After the alloy ingot is heated and melted, the Al-5%Ti master alloy is added, and when the temperature is raised to 740 degrees, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com