Aftertreatment method of 3D printing part

A 3D printing and parts technology, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problems of poor mechanical properties of parts, achieve the effect of strengthening mechanical properties and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

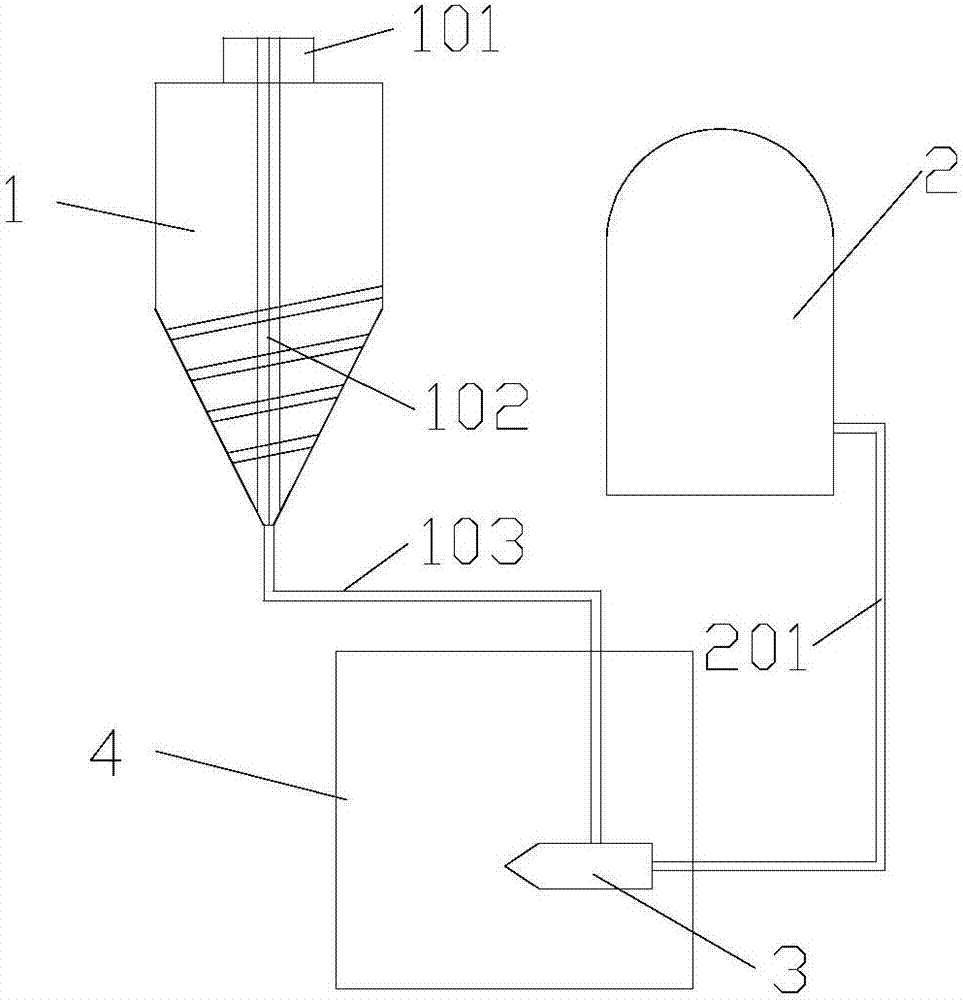

Method used

Image

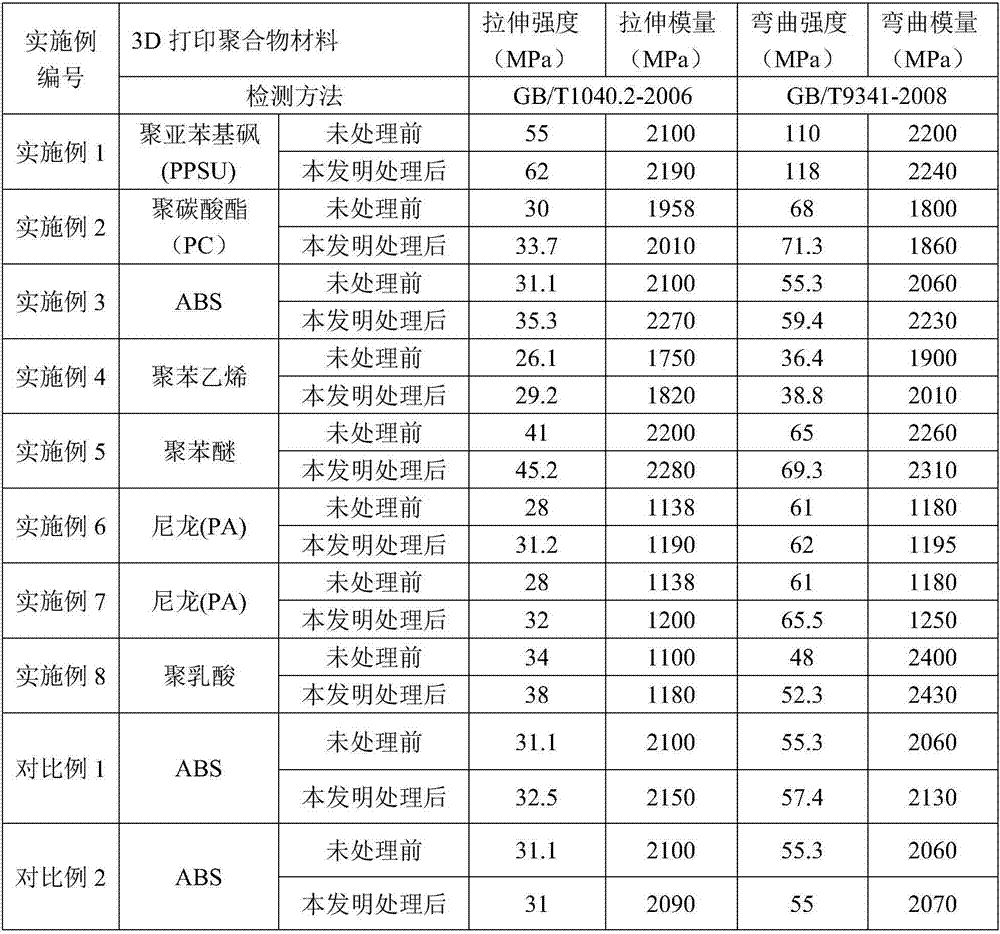

Examples

Embodiment 1

[0036] In this embodiment, the post-processing method of the 3D printed parts includes the following steps:

[0037] (1) The diameter of 2kg is 0.2mm, the micropore diameter is 300nm, and the specific surface area is 100m 2 / g, the glass microspheres are completely placed in dimethylformamide solvent, stirred and placed for 1h;

[0038] (2) Filter out the glass microbeads after absorbing dimethylformamide solvent, and then place the glass microbeads after absorbing dimethylformamide solvent in the feed device, wherein the feed of the feed device The method is spiral extrusion;

[0039] (3) The glass microbead medium after absorbing the dimethylformamide solvent is transported to the spray gun by screw extrusion in the feeding device, wherein the rotating speed of the screw extrusion rod during screw extrusion is 60 rpm;

[0040] (4) 3D printing parts are placed in a post-processing chamber with a sealed door, and the glass beads after the adsorption of dimethylformamide solv...

Embodiment 2

[0042] In this embodiment, the post-processing method of the 3D printed parts includes the following steps:

[0043] (1) The diameter of 2kg is 0.5mm, the pore diameter is 80nm, and the specific surface area is 400m 2 The ceramic microbead of / g is placed in the dichloromethane solvent completely, stirs and places 4h;

[0044] (2) Filter out the ceramic microbeads after absorbing methylene chloride solvent, then place the ceramic microbeads after absorbing methylene chloride solvent in the feeding device, wherein the feeding mode of the feeding device is screw extrusion out;

[0045] (3) The ceramic microbeads after absorbing the methylene chloride solvent are transported to the spray gun in the feeding device by means of screw extrusion, wherein the rotating speed of the screw extrusion rod during screw extrusion is 240 rpm;

[0046] (4) 3D printing parts are placed in a post-processing chamber with a sealed door, and the ceramic microbeads after the adsorption of dichlorom...

Embodiment 3

[0048] In this embodiment, the post-processing method of the 3D printed parts includes the following steps:

[0049] (1) The diameter of 3kg is 0.4mm, the micropore diameter is 120nm, and the specific surface area is 300m 2 / g of ceramic microbeads is completely placed in acetone solvent, stirred and placed for 3.5h;

[0050] (2) filtering out the ceramic microbeads after absorbing the acetone solvent, and then placing the ceramic microbeads after absorbing the acetone solvent in the feeding device, wherein the feeding mode of the feeding device is screw extrusion;

[0051] (3) The ceramic microbeads after absorbing the acetone solvent are transported to the spray gun in the feeding device by means of screw extrusion, wherein the rotating speed of the screw extrusion rod during screw extrusion is 180 rpm;

[0052] (4) The 3D printed parts are placed in a post-processing chamber with a sealed door, and the ceramic microbeads after the adsorption of acetone solvent enter the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com