Aging method of distilled spirit

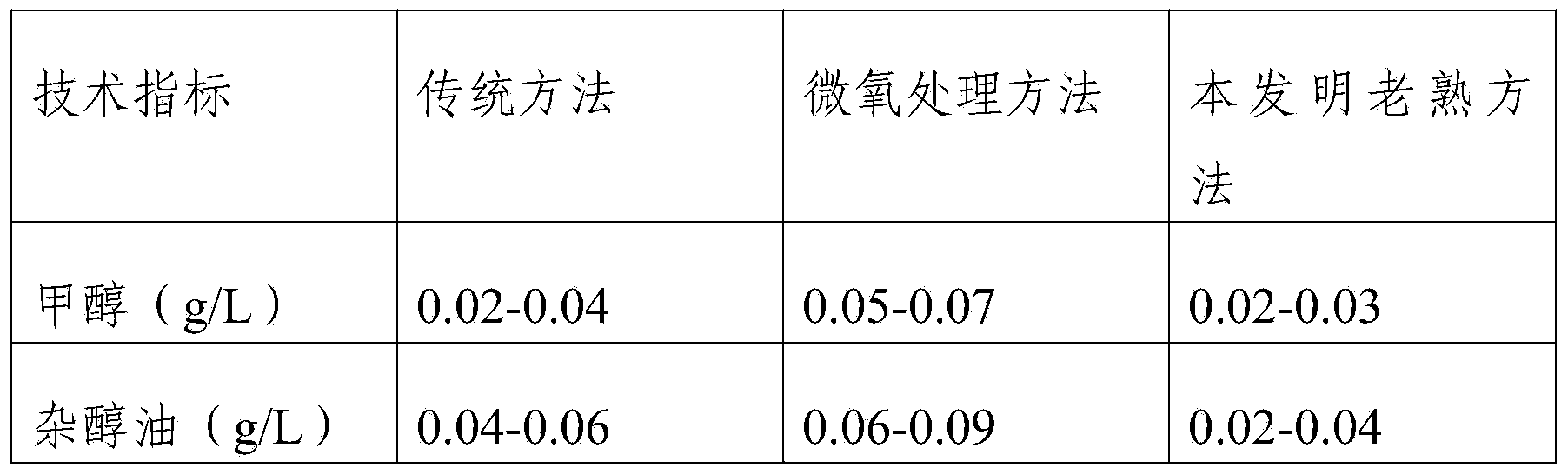

An aging and liquor technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of easy introduction of impurities, high equipment requirements, long storage time, etc., and achieve the effect of reducing storage time, accelerating physical and chemical reactions, and having a strong aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for aging liquor, the method comprising the following steps:

[0022] a. Wine storage: Put the wine into the wine storage container and seal it, then put the wine storage container containing the wine into a closed wine storage with a temperature of 10°C, and store it for 48 hours. The closed wine storage is equipped with a steam guide ;

[0023] b. Wine steam introduction: the wine steam is introduced into the wine storage through the steam pipe, and the introduction of the wine steam is carried out three times. The wine steam is introduced for the first time to control the temperature of the wine storage to rise to 20°C, and then the steam is stopped. After an interval of 240h Carry out the second steaming, control the temperature of the wine storage to rise to 31°C, stop the steaming, and perform the third steaming after an interval of 360 hours, and control the temperature of the wine storage to rise to 40°C;

[0024] c. Temperature-controlled storage: Aft...

Embodiment 2

[0026] A method for aging liquor, the method comprising the following steps:

[0027] a. Wine storage: Put the wine into the wine storage container and seal it, then put the wine storage container containing the wine into a closed wine storage with a temperature of 11°C, and store it for 48 hours. There is a steam guide in the closed wine storage Tube;

[0028] b. Wine steam introduction: the wine steam is introduced into the wine storage through the steam pipe, and the introduction of the wine steam is carried out three times. The first time the wine steam is introduced to control the temperature of the wine storage to rise to 22°C, then the steam is stopped. After an interval of 220h Carry out the second steaming, control the temperature of the wine storage to rise to 32°C, stop the steaming, and perform the third steaming after an interval of 340 hours, control the temperature of the wine storage to rise to 41°C;

[0029] c. Temperature-controlled storage: After the third ...

Embodiment 3

[0031] A method for aging liquor, the method comprising the following steps:

[0032] a. Wine storage: Put the wine into the wine storage container and seal it, then put the wine storage container containing the wine into a closed wine storage with a temperature of 12°C, and store it for 48 hours. There is a steam guide in the closed wine storage Tube;

[0033] b. Wine steam introduction: the wine steam is introduced into the wine storage through the steam pipe, and the introduction of the wine steam is carried out three times. The first time the wine steam is introduced to control the temperature of the wine storage to rise to 23°C, then the steam is stopped. After an interval of 200h Carry out the second steaming, control the temperature of the wine storage to rise to 33°C, stop the steaming, and perform the third steaming after an interval of 320 hours, control the temperature of the wine storage to rise to 42°C;

[0034] c. Temperature-controlled storage: After the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com