Bag conveying mechanism for bagging machine

A bagging machine and conveying bag technology, which is applied in the direction of transportation and packaging, object separation, plant protection cover, etc., can solve the problems affecting the normal operation of the bagging machine and the work disorder of the bagging machine, so as to save the time of bagging and opening bags , Improve the effect of bagging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

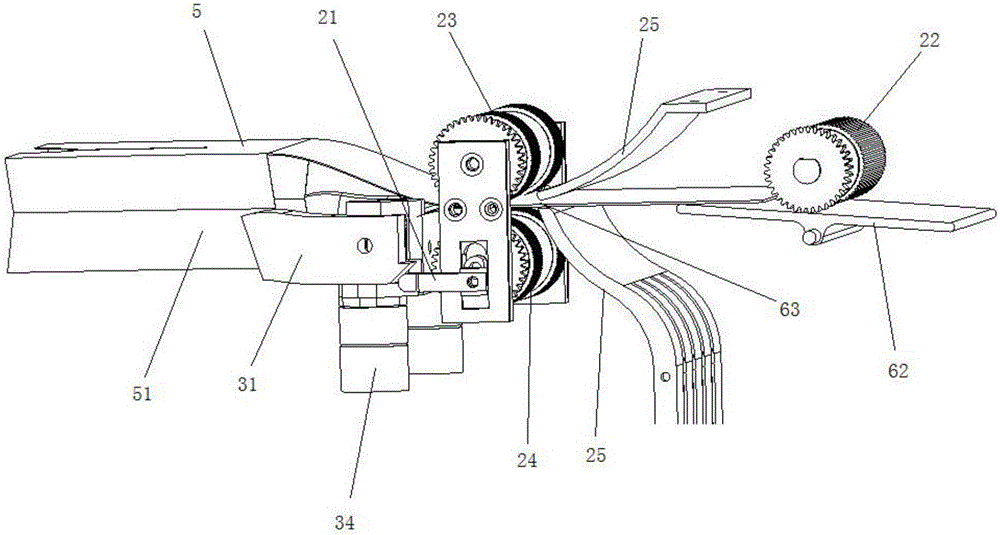

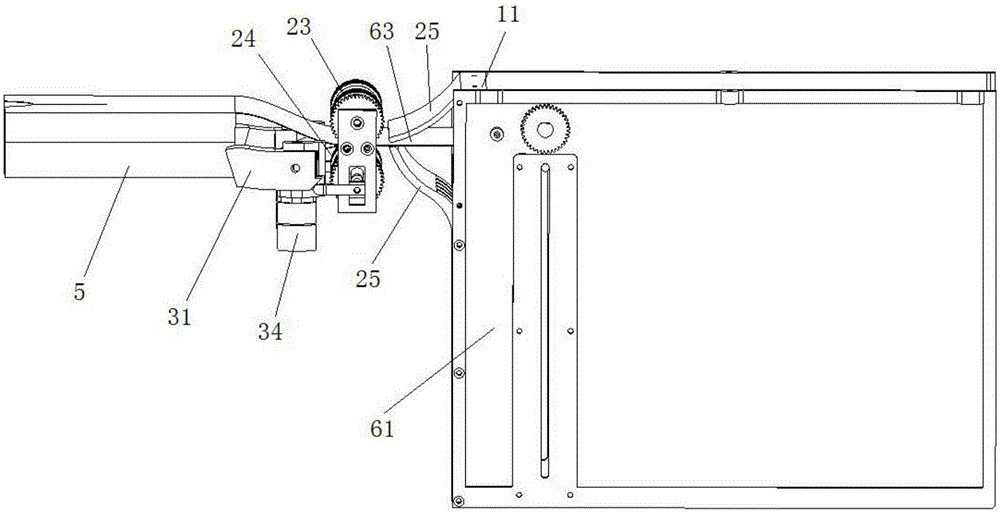

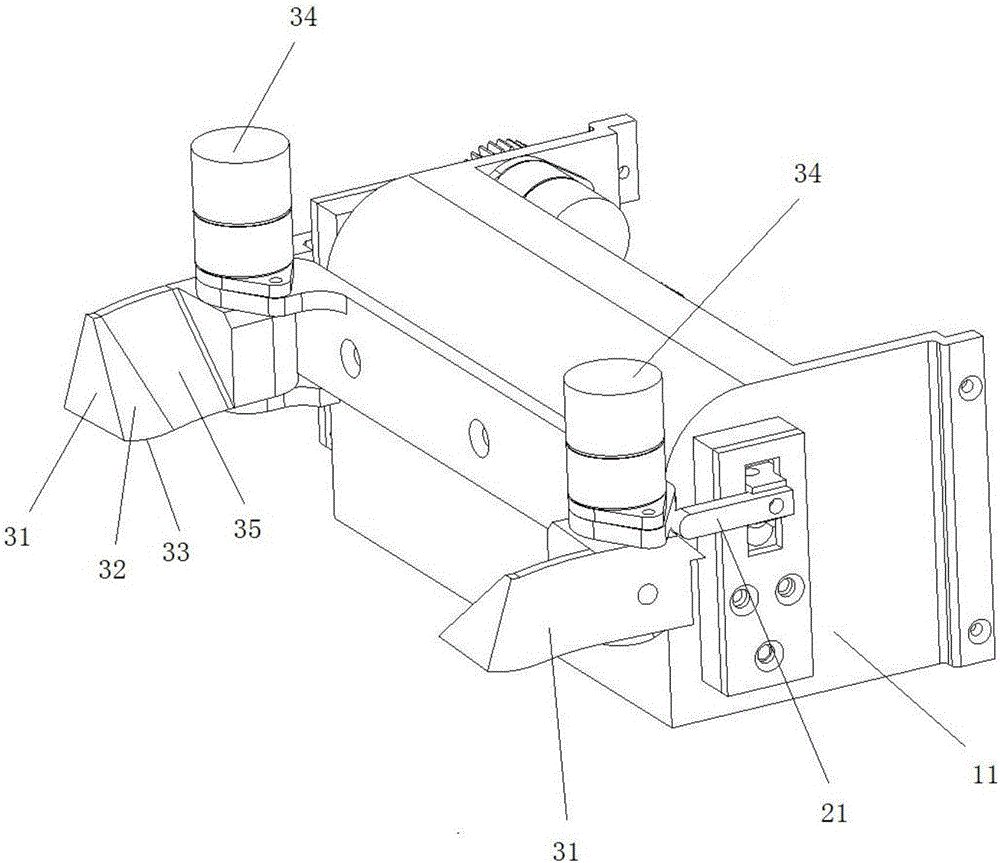

[0027] see Figure 1-2 , a bag delivery mechanism of a bagging machine, which includes a bag-out rubbing wheel 22 arranged above the inner cavity of the bag storage box 61, and the bag-out rubbing wheel 22 and the uppermost layer in the bag storage box 61 Folding the bagging contact, the bag storage box 61 is provided with a supporting plate 62, and several bagging stacked up and down are placed in the cavity between the supporting plate 62 and the bag-out pickup wheel 22 , the supporting plate 62 is driven by an elastic mechanism to lift the bagging to the side of the bag-out pickup wheel 22, and the bag-out pickup wheel 22 rotates in the forward direction to contact it by the friction between it and the paper bag The bagging is rubbed out from the bag outlet 63 of the bag storage box 61, and the outside of the bag storage box 61 is provided with a delivery wheel at the bag outlet 63, and the delivery wheel includes an upper delivery wheel 23 and a lower delivery wheel. Whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com