Automatic quantitative bagging machine

A quantitative bagging and bagging machine technology, applied in the directions of packaging, transportation and packaging, special packaging objects, etc., can solve the problems affecting the yield and quality of edible fungi, different lengths, and uneven tightness of fungus bags, and improve production conditions. , The effect of reducing production cost and high bagging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

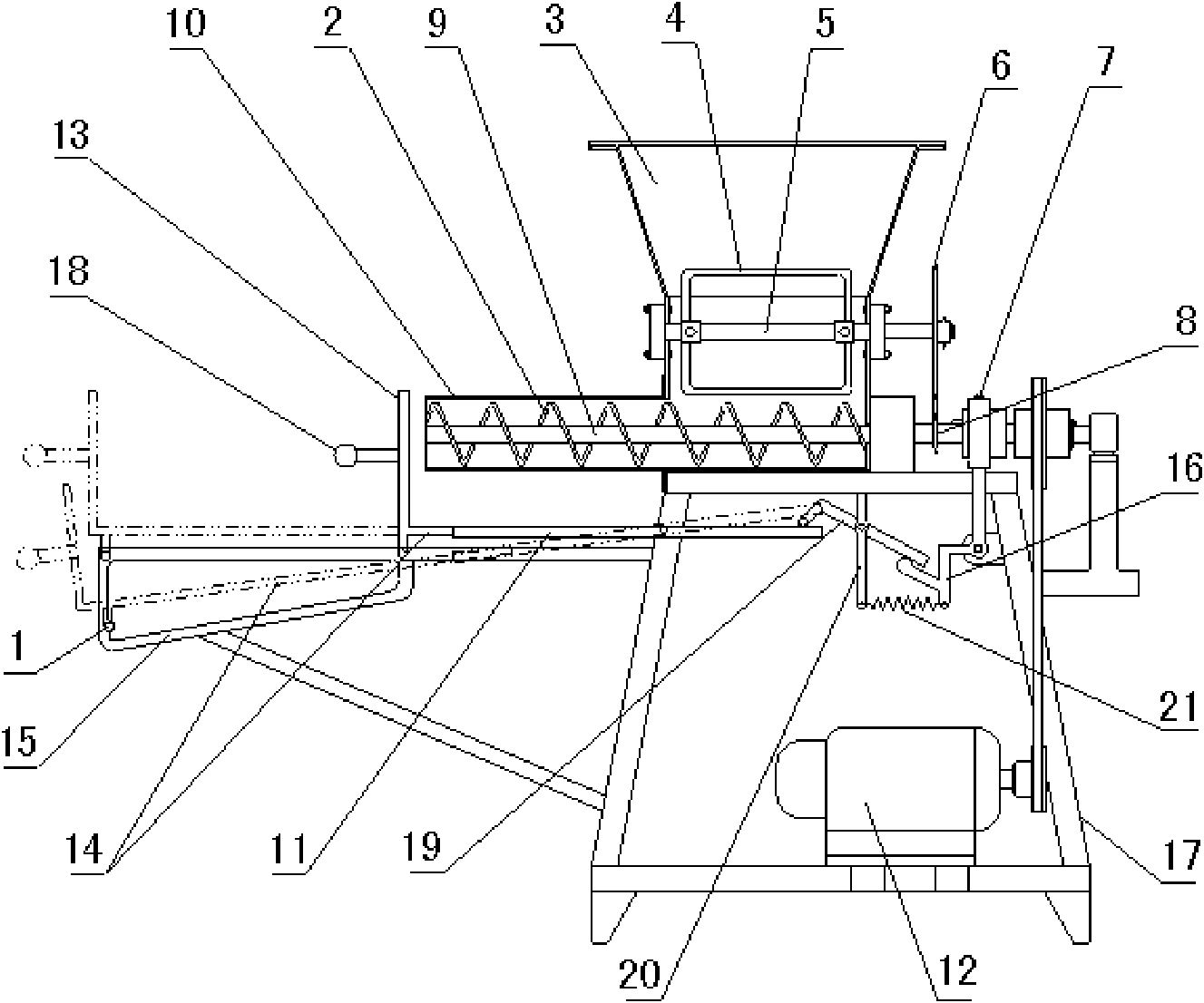

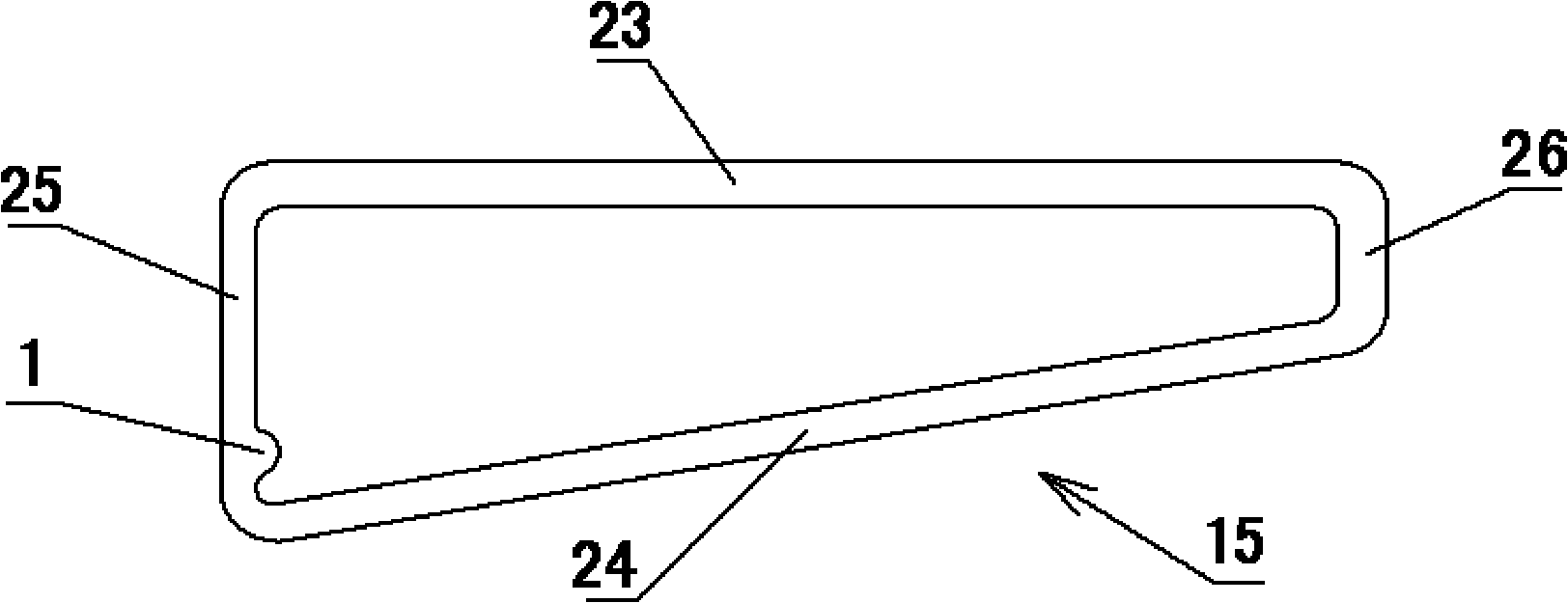

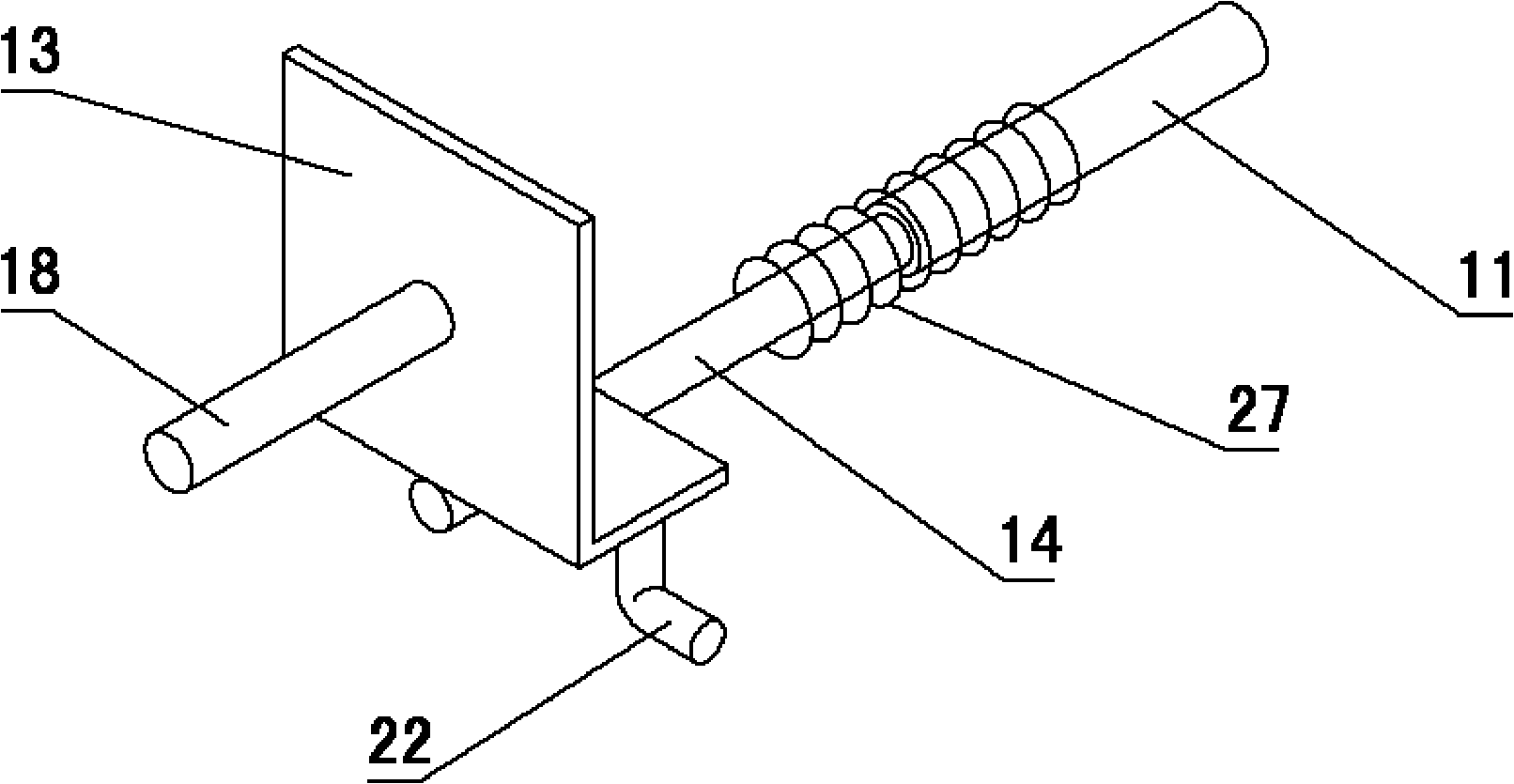

[0021] in such as figure 1 In the shown embodiment 1, an automatic quantitative bagging machine includes a frame 17, a motor 12, a feed device and a discharge device, and the discharge device includes a discharge pipe 10 and a device arranged in the discharge pipe. The auger 2 is provided with a clutch 7 on the auger shaft 9, a bag holder 13 is provided on the side near the outlet of the discharge pipe, and a sliding shaft 22 is arranged on the bag holder, and the sliding shaft is arranged on both sides of the bag holder Below, the bag holder is provided with a handle 18 on one side away from the discharge port. The guide groove 15 that is arranged on both sides of the discharge port is a right-angled trapezoidal structure, and the guide groove 15 includes an upper groove 23, a lower groove 24, a long straight groove 25 and a short straight groove 26 (see figure 2 ), the upper groove is parallel to and close to the discharge pipe, and the length of the upper groove matches t...

Embodiment 2

[0023] Both the connecting rod and the sleeve rod used in embodiment 2 are of square tube structure, the connecting rod is slidingly sleeved in the sleeve rod, the elastic structure is a tension spring, which is arranged inside the connecting rod and the sleeve rod, and one end of the tension spring is fixed on the connecting rod , and the other end is fixed on the hinge shaft between the sleeve rod and the frame. All the other are identical with embodiment 1.

[0024] When the bagging machine of the present invention is working, the bacterial material is put into the hopper, and under the agitation of the continuously rotating stirring wings, the raw material evenly falls onto the auger in the discharge pipe, and the bacterial material is transported to the outlet of the discharge pipe through the auger. , so as to achieve the purpose of filling the fungus material bag sleeved on the discharge pipe. The auger shaft at the auger rear portion is provided with a clutch, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com