Cereal bagging machine for sunning ground

A bagging machine and grain technology, applied in the field of grain bagging machines, can solve the problems of low bagging efficiency, no cleaning function, poor traveling performance, etc., and achieve high bagging efficiency, simple structure, and low processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described specific embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

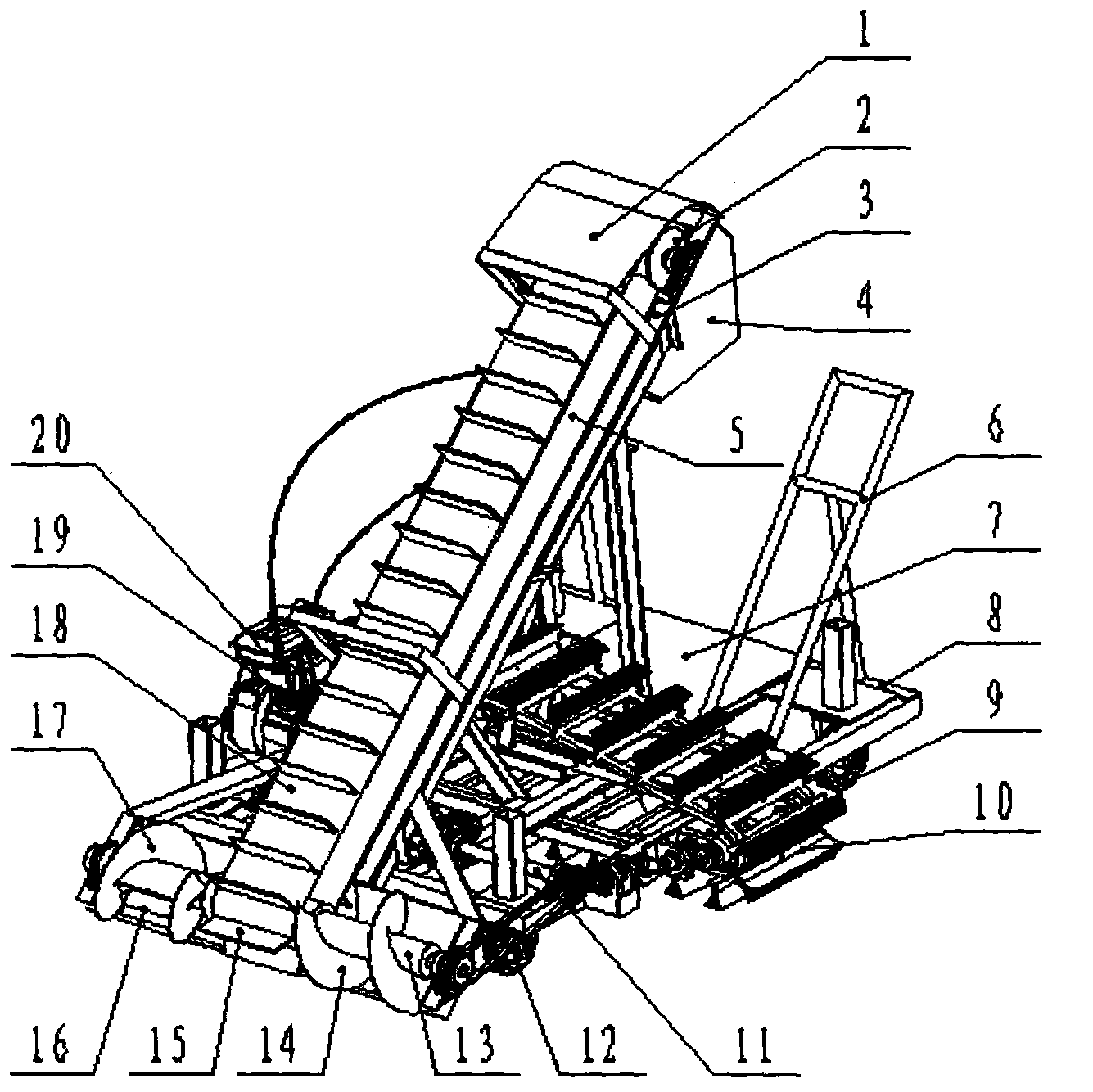

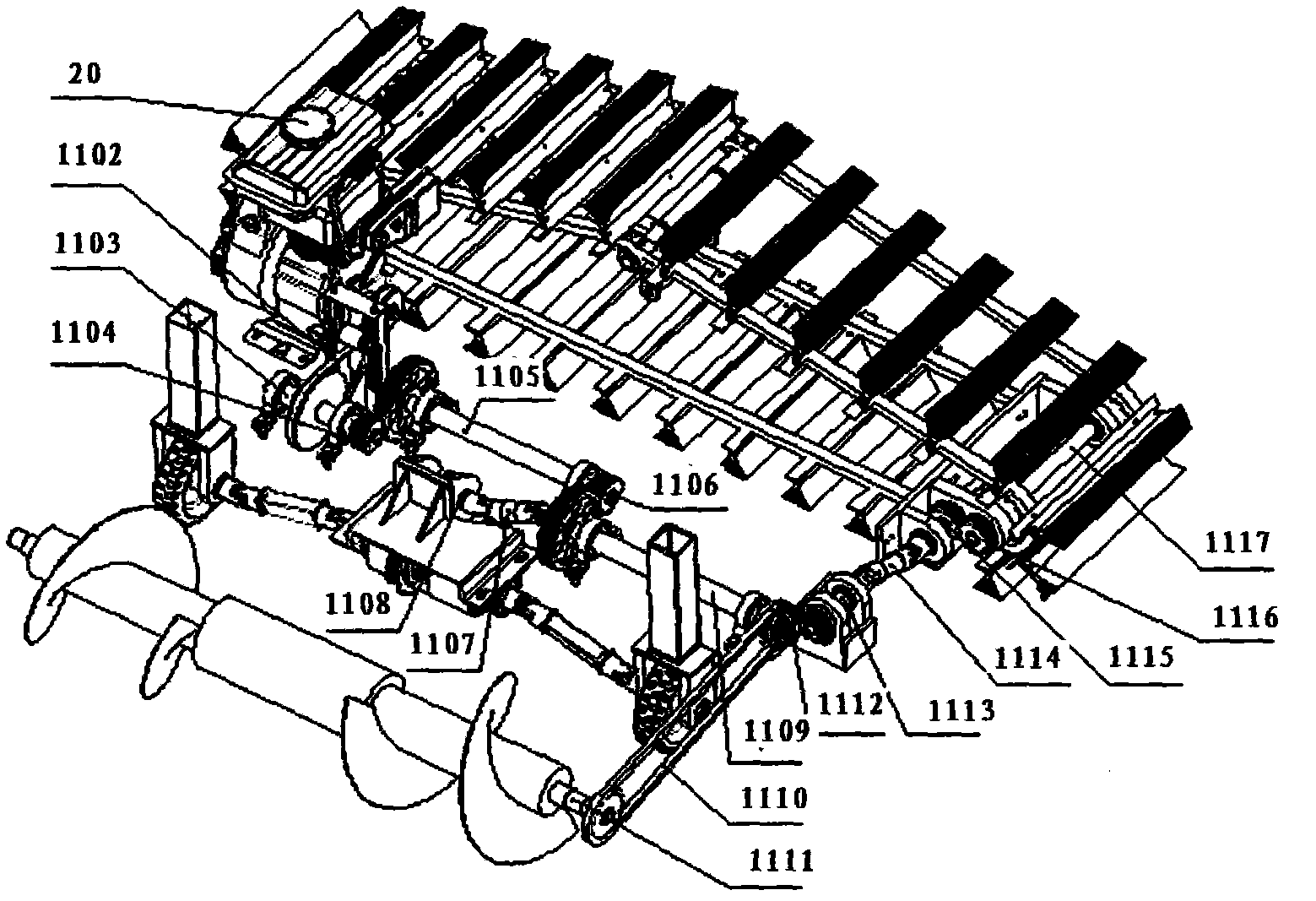

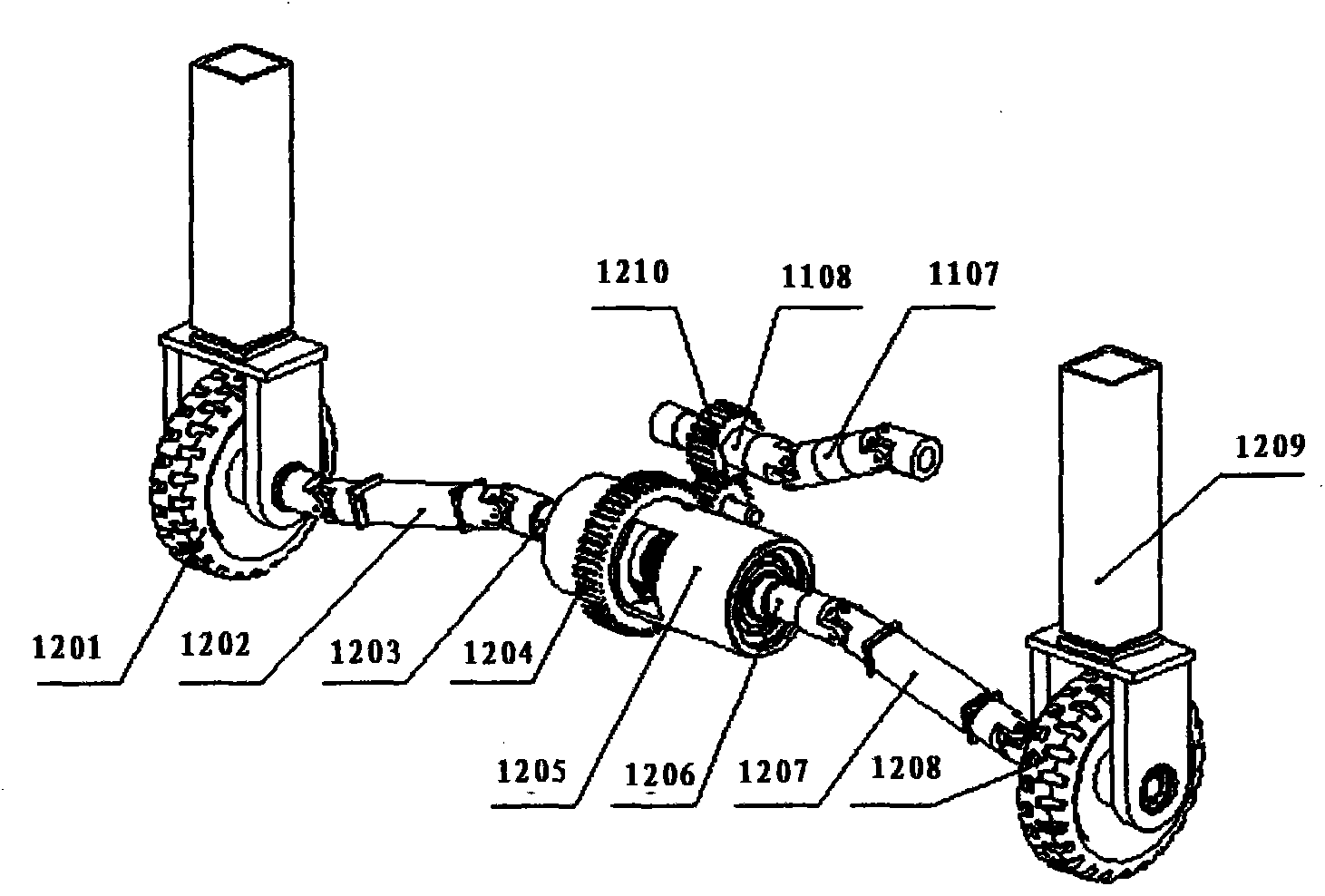

[0021] The drying field grain bagging machine of the present invention includes a vehicle frame 8 and an engine 20 , and a cleaning device 10 and a transmission device 11 are arranged below the vehicle frame 8 . The top of vehicle frame 8 is equipped with the grain delivery device 5 that tilts to set, and the front end of grain delivery device 5 is provided with screw delivery shaft 13, front circular arc plate 16, and the left and right sides of screw delivery shaft 13 are provided with left helical blade 14, right helical blade. Blade 17, rear roller 2 is established at the rear end of grain conveyor 5, and the height of rear roller 2 is greater than the height of screw conveyor shaft 13, and conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com