Automatic young fruit bagging machine

A bagging machine and young fruit technology, applied in the field of automated young fruit bagging machines, can solve the problems of affecting fruit yield and bagging efficiency, unable to meet the needs of orchard bagging, unreasonable design of fork plate devices, etc. Bag efficiency, avoid accidental breakage, prevent injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

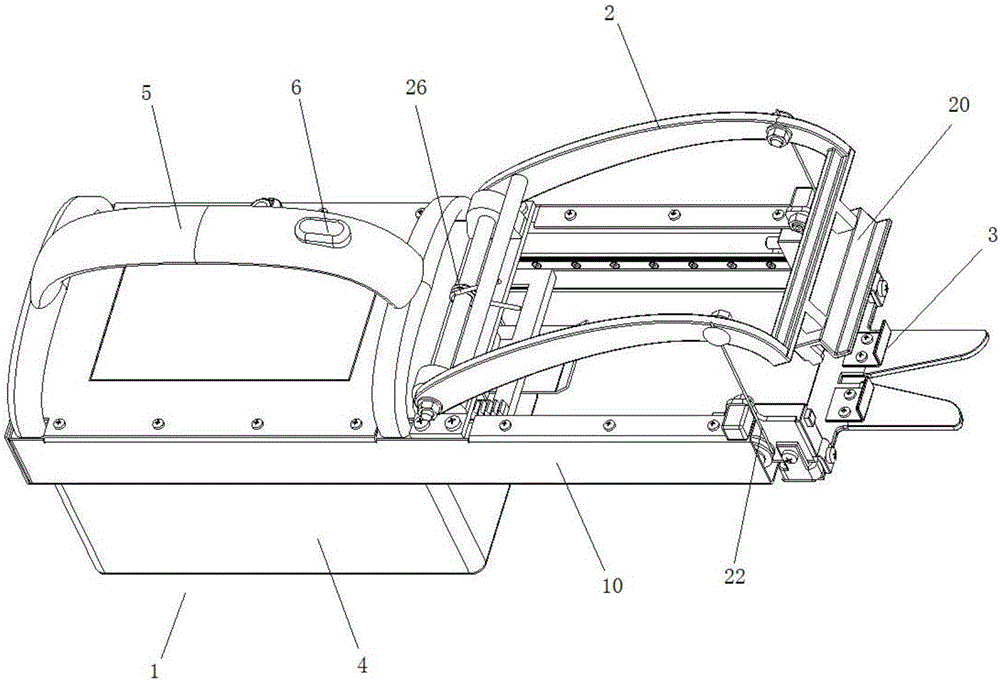

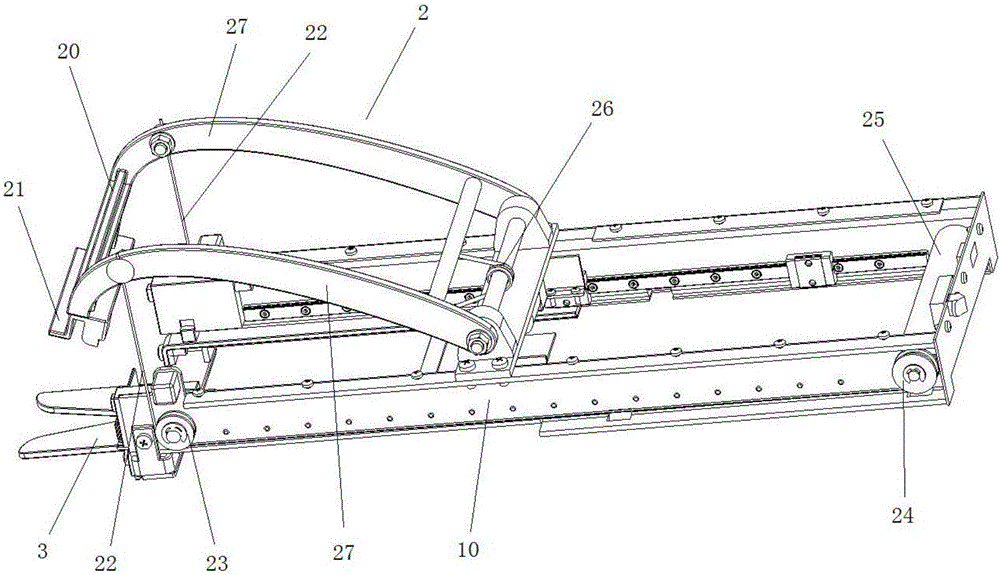

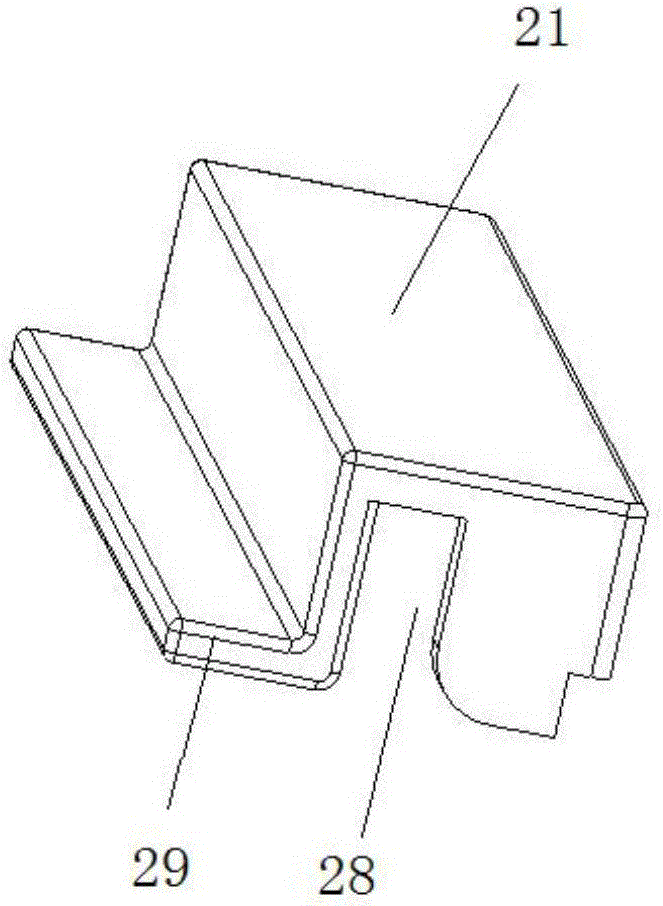

[0027] see Figure 1-2 , an automatic young fruit bagging machine 1, which includes an upper pressing frame 2 and a fork plate device 3, the upper pressing frame 2 includes a pressing fork 20, and one end of the pressing fork 20 is hinged on the young fruit cover On the frame 10 of the bagging machine 1, the other end of the pressing fork 20 is equipped with a pressing plate 21 for pressing the iron wire of the bagging mouth from the upper end, and the pressing plate 21 is arranged on the fork of the young fruit bagging machine 1. The top of the plate device 3; the bottom of the frame 1 is provided with a bag storage box 4, and an automatic bag loading device is provided in the bag storage box 4, and the upper end of the bag storage box 4 is provided with a device for transporting bags to The automatic bag feeding device of the pressing position; the top of the frame 1 is provided with a handle 5, the handle 5 is located directly above the bag storage box 4, and the handle 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com