Patents

Literature

32results about How to "Improve pressing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

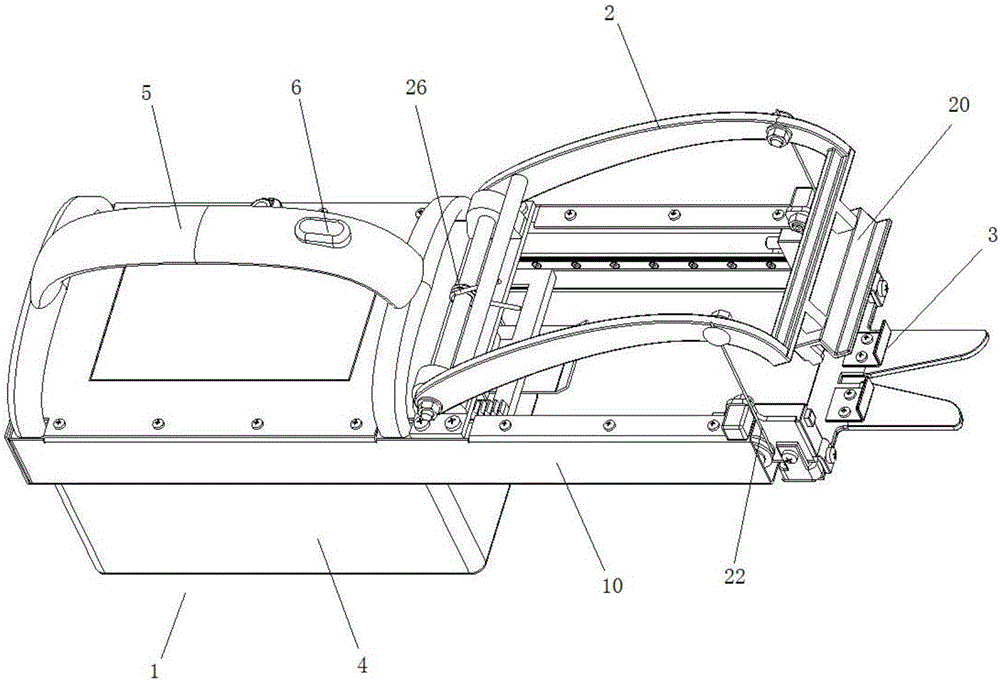

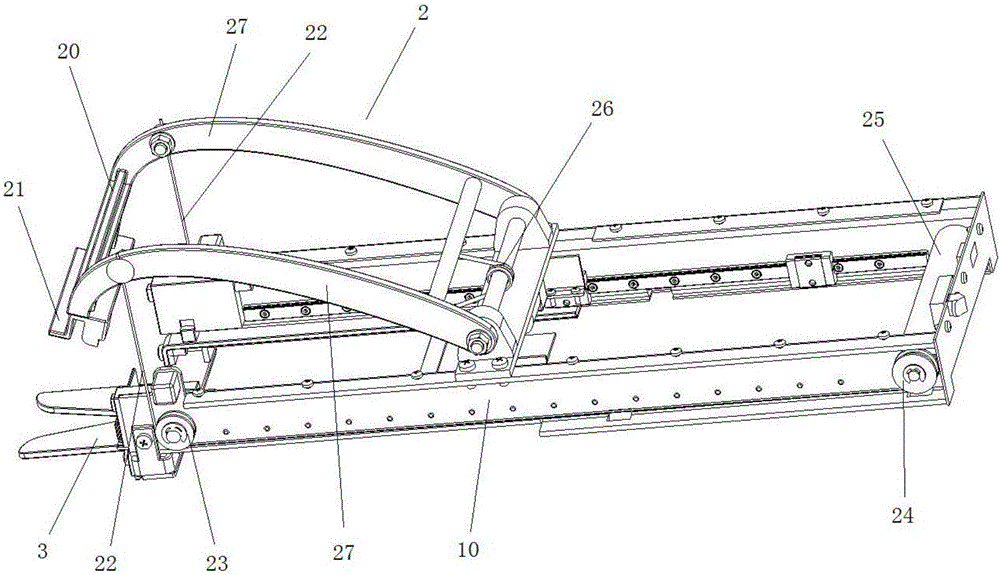

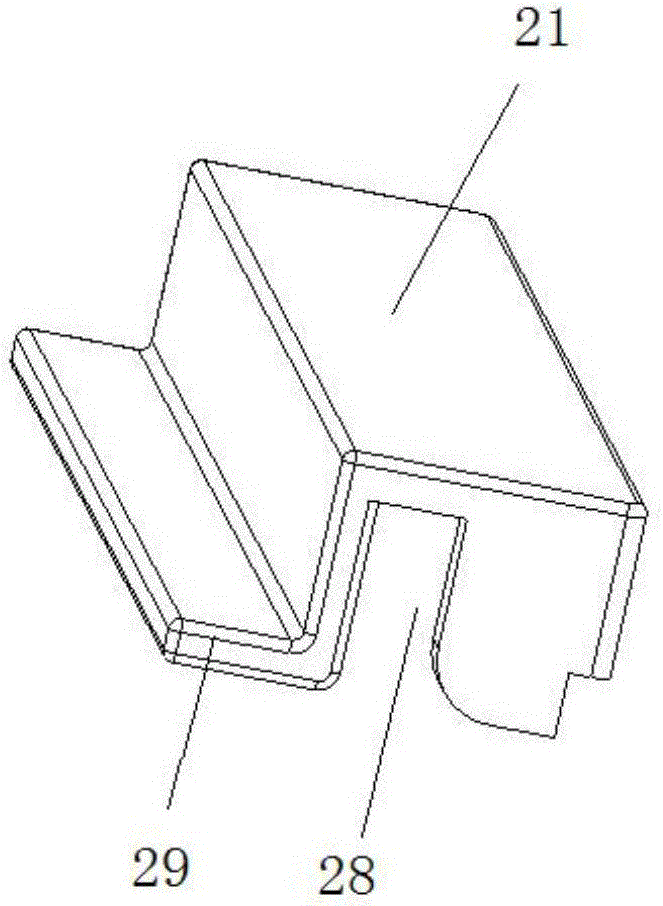

Automatic young fruit bagging machine

ActiveCN105918025AAvoid harmAvoid accidental breakagePlant protective coveringsDrive wheelElectric machinery

The invention discloses an automatic young fruit bagging machine. The automatic young fruit bagging machine comprises an upper press fit frame and a fork plate device, wherein the upper press fit frame comprises a pressing fork; one end of the pressing fork is hinged to a frame; a pressure plate is arranged at the other end of the pressing fork; the pressure plate is arranged above the fork plate device; a bag storing box is arranged below the frame; an automatic bag loading device is arranged in the bag storing box; an automatic bag feeding device is arranged at the upper end of the bag storing box; a handle is arranged above the frame; the handle is provided with a control switch; the fork plate device is provided with two fork plates stretching in a V shape; one end of the pressing fork is fixedly connected with a stay cord; the stay cord is connected to a driving wheel at the back end of the frame after crossing a driven wheel; the driving wheel is driven by a motor; the control switch is used for controlling the motor to rotate forwards or backwards. By adopting the automatic young fruit bagging machine, automatic press fit bagging can be realized, thereby increasing the bagging efficiency, and lowering the labor intensity; a V-shaped opening design is adopted at the front end of the fork plate device, so that the problem of fracture of fruit stems in a bagging process is effectively solved.

Owner:好果子农业科技(北京)有限公司

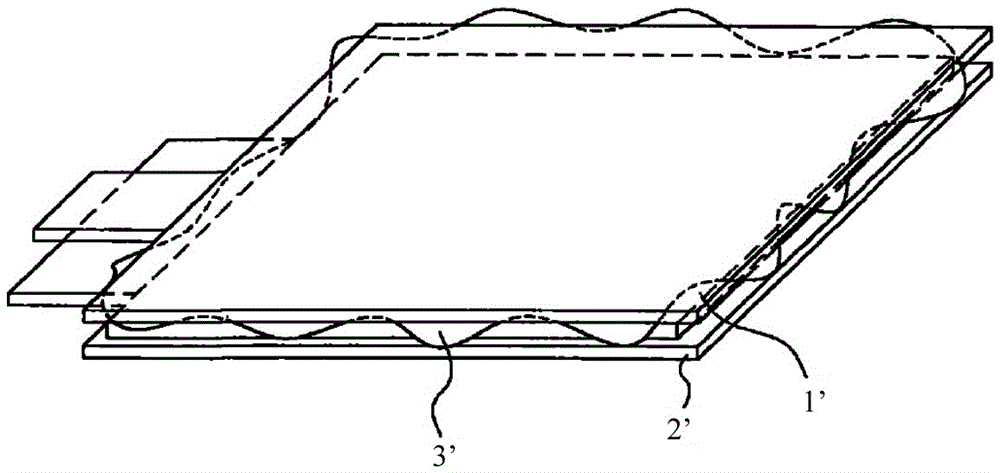

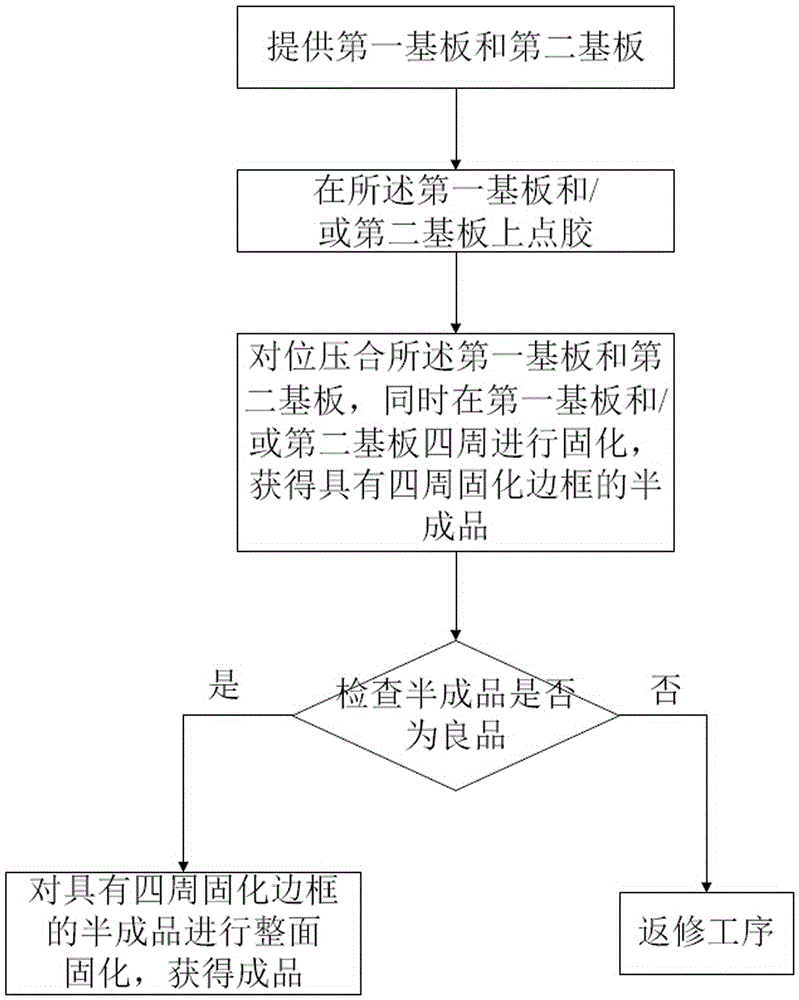

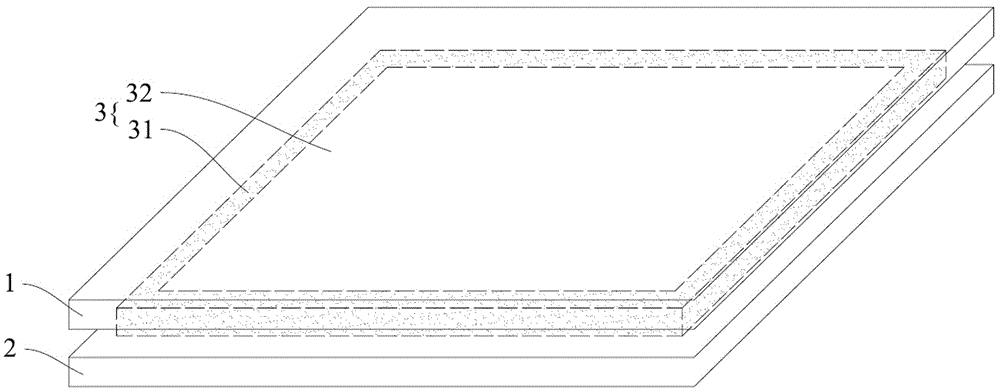

Glue laminating process

InactiveCN105774184APrecise Width ControlEasy to operateLamination ancillary operationsLaminationProduction lineColloid

The invention provides a glue laminating process. The glue laminating process comprises the following steps: (1) providing a first substrate and a second substrate; (2) dispensing a glue to the first substrate and / or the second substrate; (3) carrying out aligned press-fitting on the first substrate and the second substrate, and meanwhile, curing the periphery of the first substrate and / or the second substrate so as to obtain a semifinished product with a periphery-cured frame; and (4) carrying out surface-dressing curing on the semifinished product with the periphery-cured frame, thereby obtaining a finished product. According to the glue laminating process, the periphery of the substrates is cured while the aligned press-fitting of the substrates is completed so as to obtain the periphery-cured frame, thus, the problem of glue overflowing is effectively solved, the width of overflowed glue can be accurately controlled, the broadening of the glue does not occur after curing, secondary misalignment does not occur after curing, the accuracy of press-fitting is further improved, and the actual operation of a production line is facilitated; and the problem of press-fit bubbles can be effectively solved, the leveling of the glue is accelerated, the production time is shortened, and the production efficiency is further increased.

Owner:TRULY OPTO ELECTRONICS

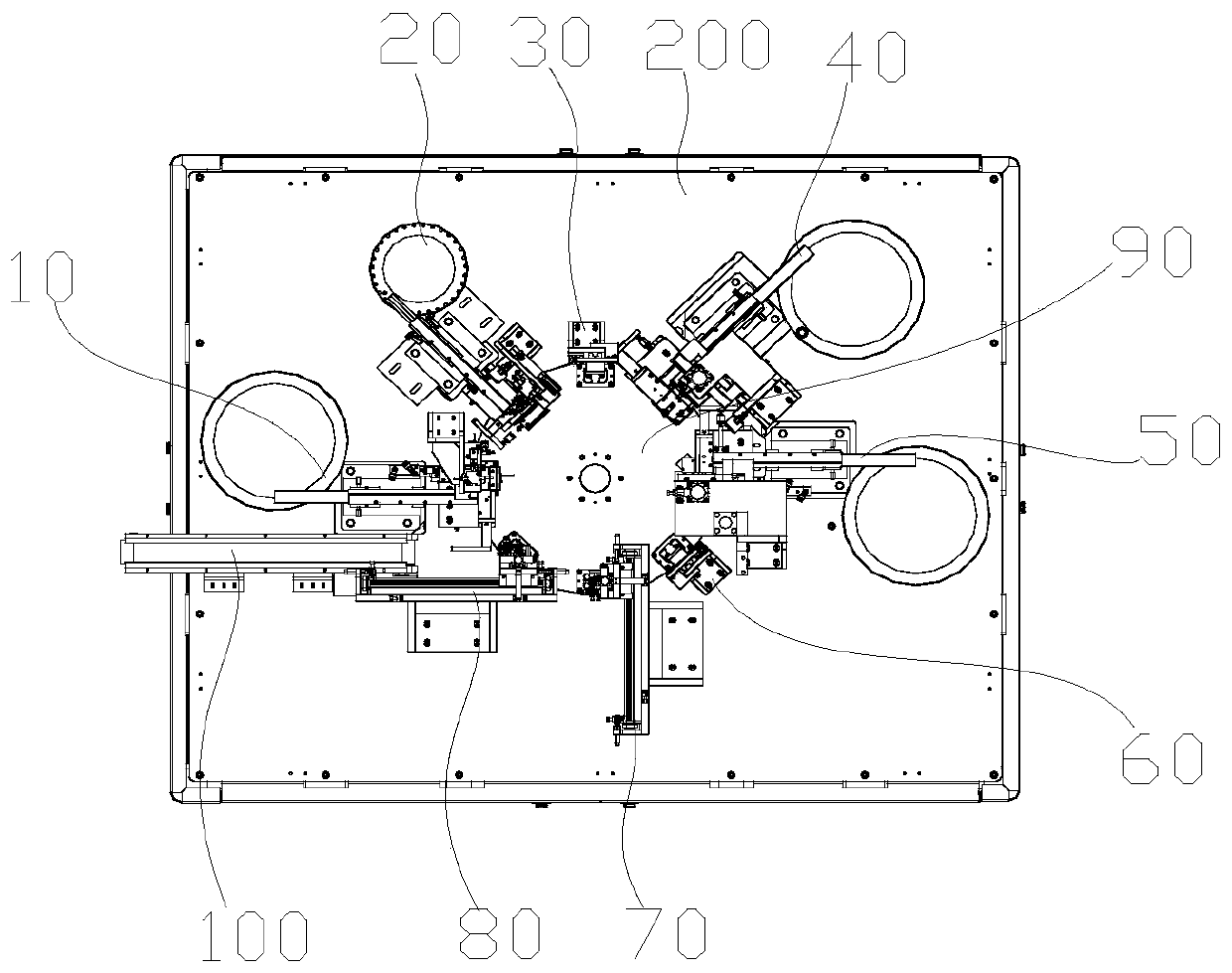

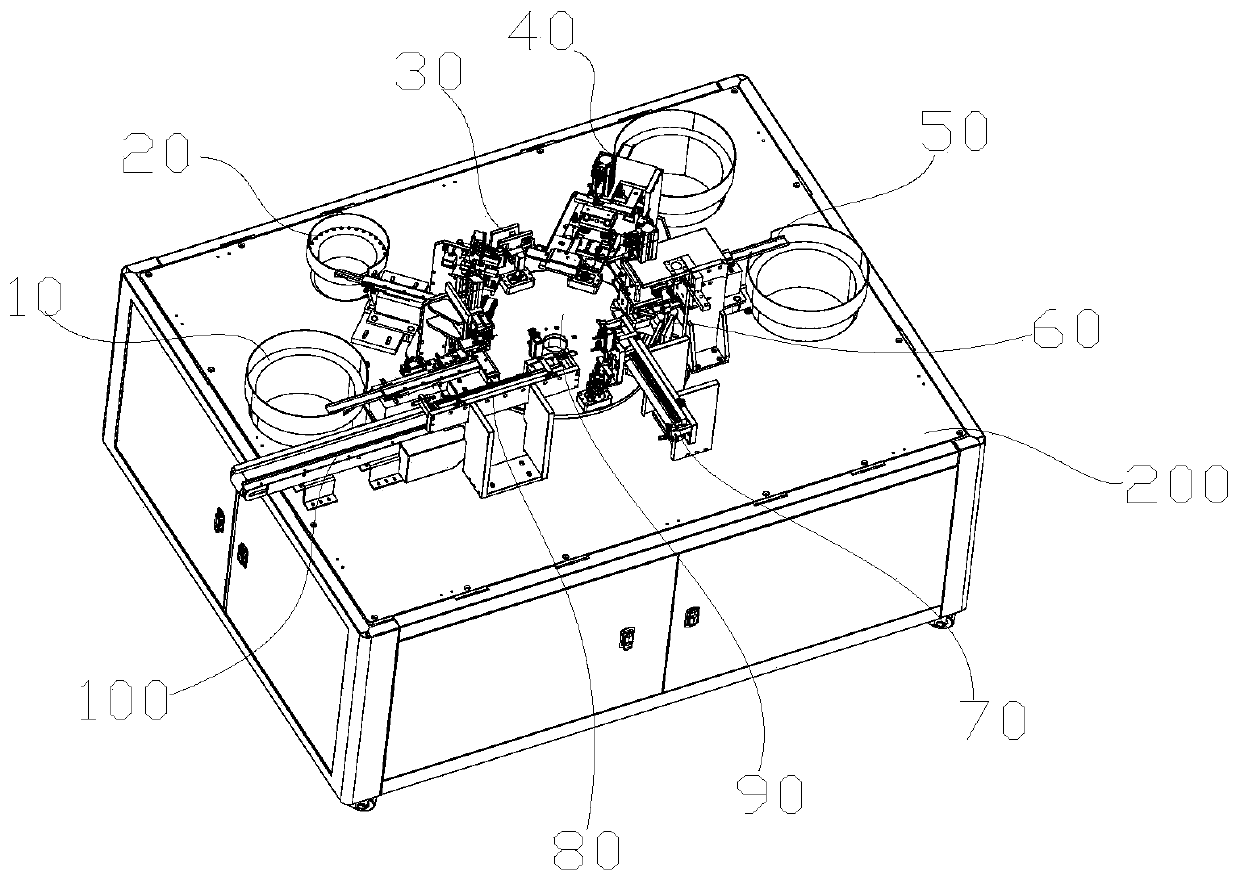

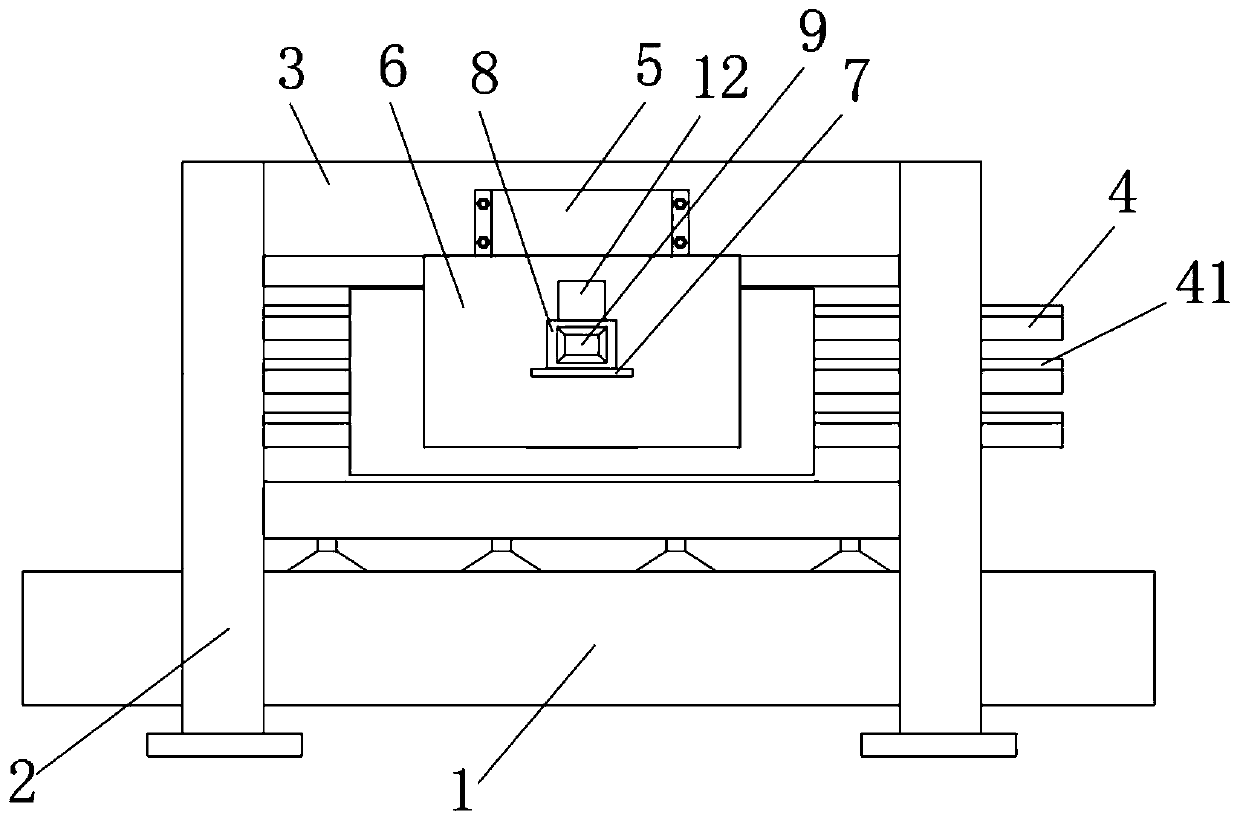

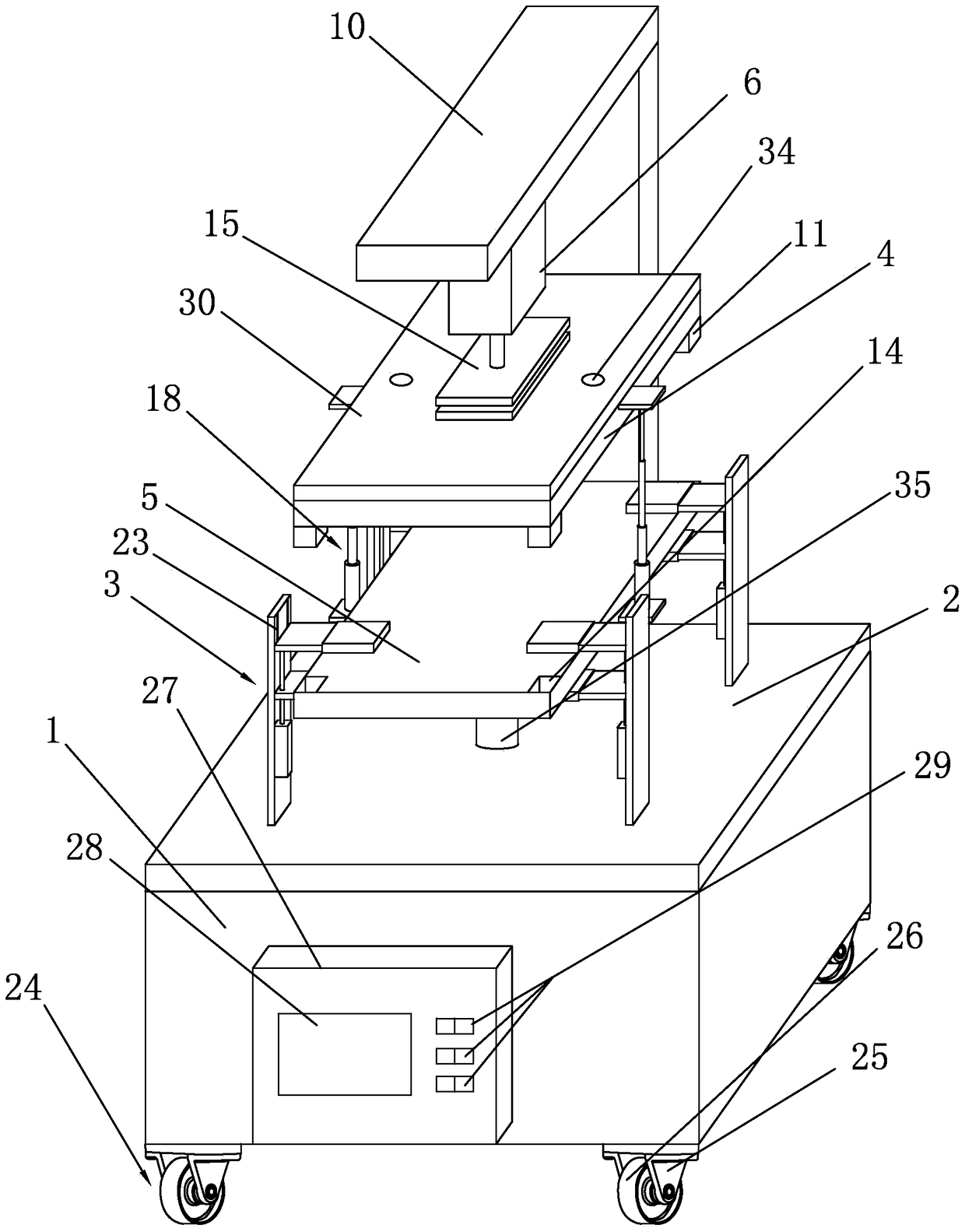

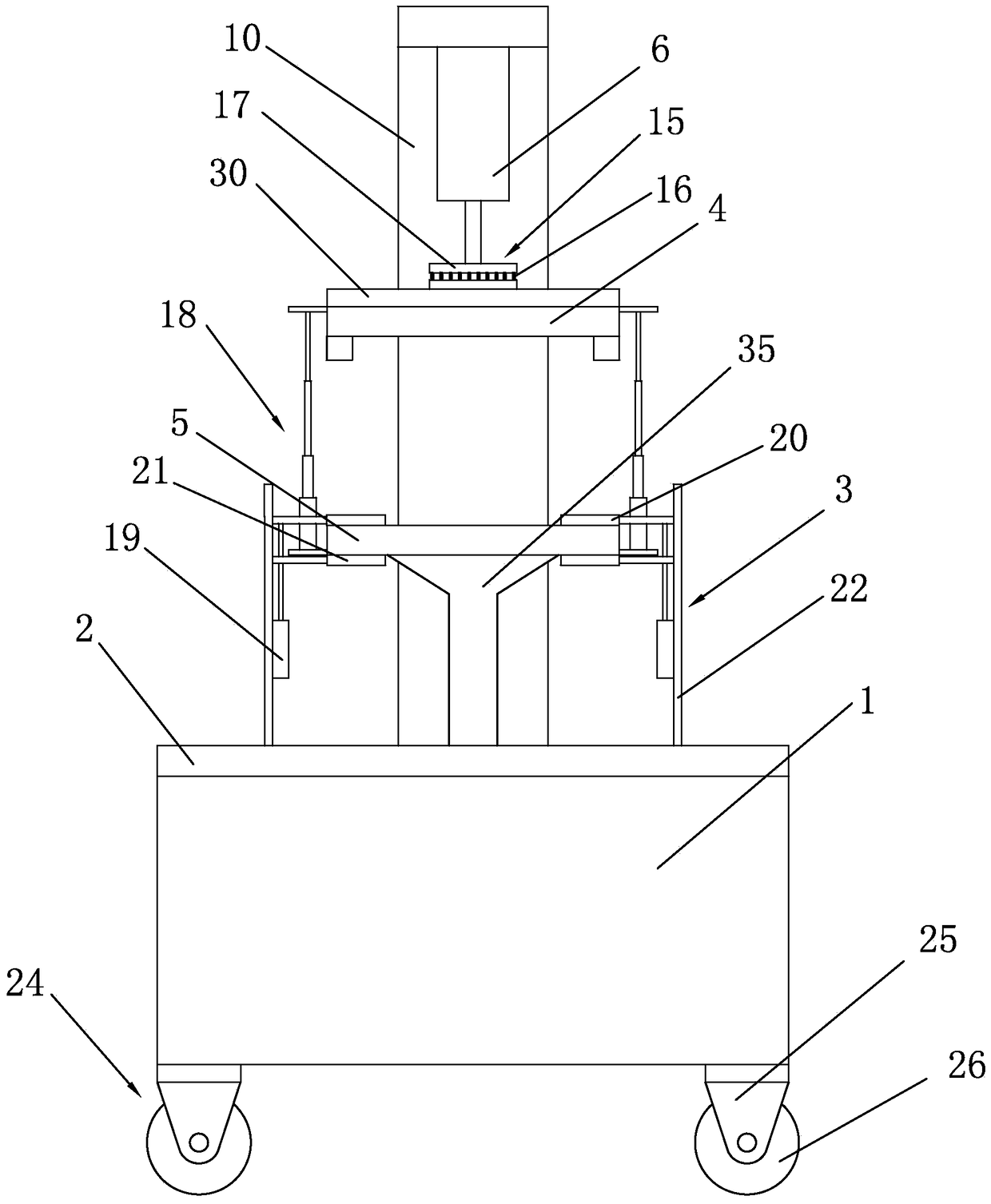

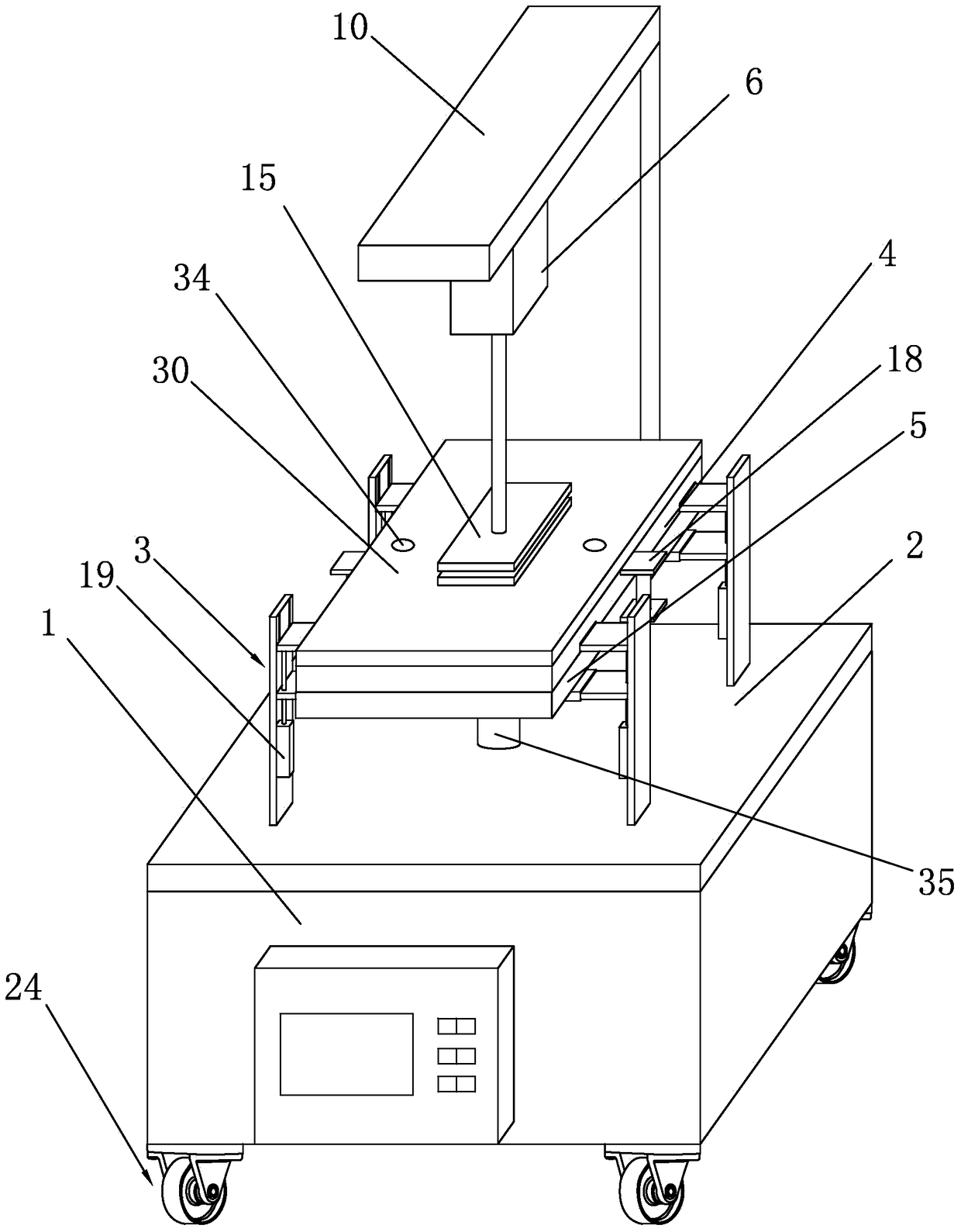

Press-fitting machine for bearings

PendingCN111230494APrevent leakageImprove yield rateAssembly machinesMetal working apparatusProcess engineeringMachine

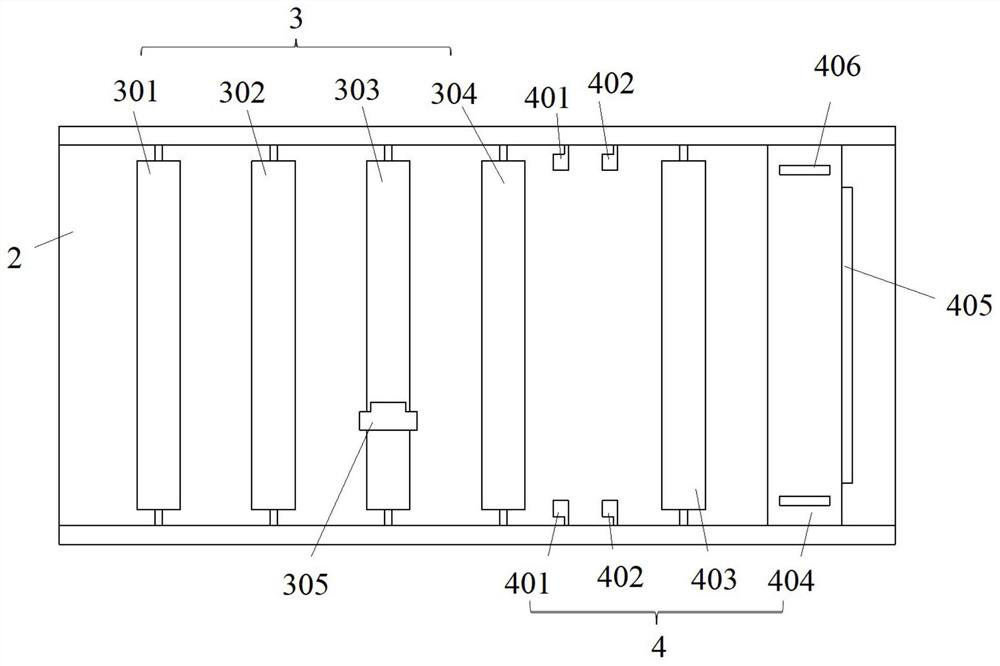

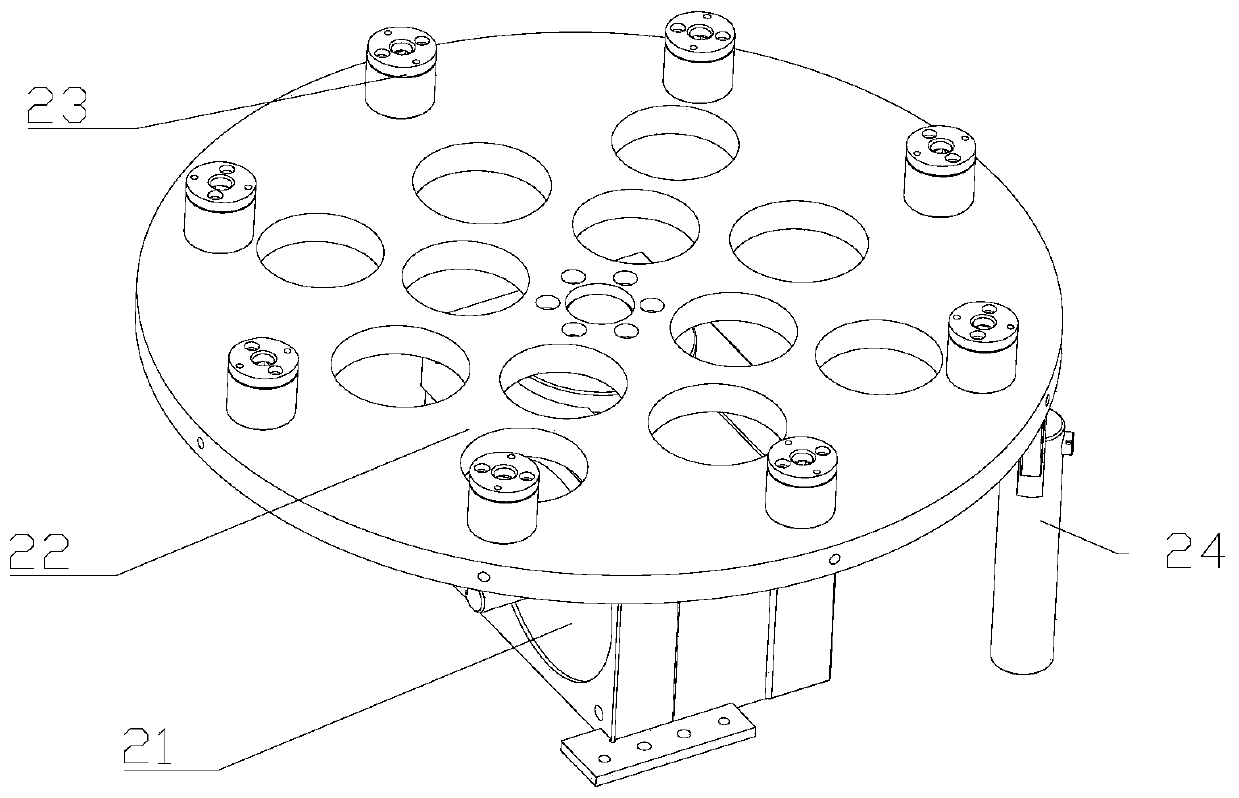

The invention puts forward a press-fitting machine for bearings. The press-fitting machine comprises a workbench as well as a conveying mechanism, a first feeding mechanism, a second feeding mechanism, a third feeding mechanism, a fourth feeding mechanism, a first detecting mechanism, a second detecting mechanism, a first discharging mechanism and a second discharging mechanism which are arrangedon the workbench; and the first feeding mechanism, the second feeding mechanism, the third feeding mechanism, the fourth feeding mechanism, the first detecting mechanism, the second detecting mechanism, the first discharging mechanism and the second discharging mechanism are arranged around the conveying mechanism. By the aid of the press-fitting machine for the bearings, first bearings, second bearings, gaskets and V-wheels can be press-fitted together automatically, so that the production efficiency is greatly improved, and the safety problems caused by manual operations are avoided. The first detecting mechanism and the second detecting mechanism are arranged, so that the press-fitting precision can be improved, the conditions of missing of the gaskets during operations can be avoided,and the yield of semi-finished products can be greatly increased.

Owner:SHENZHEN CREALITY 3D TECH CO LTD

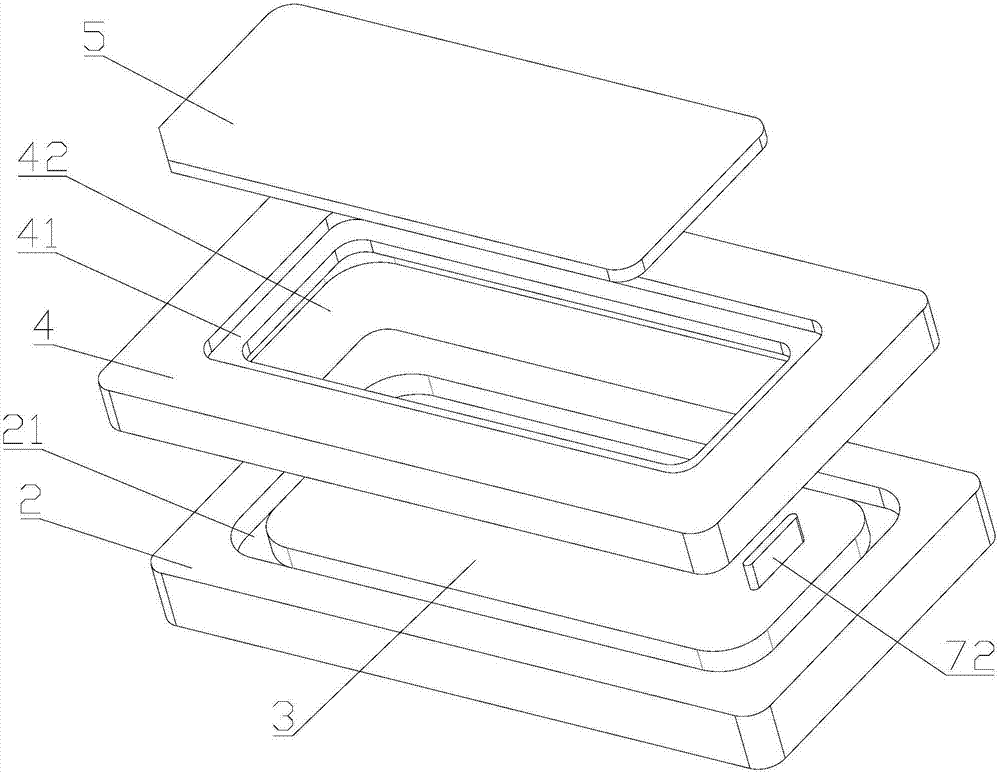

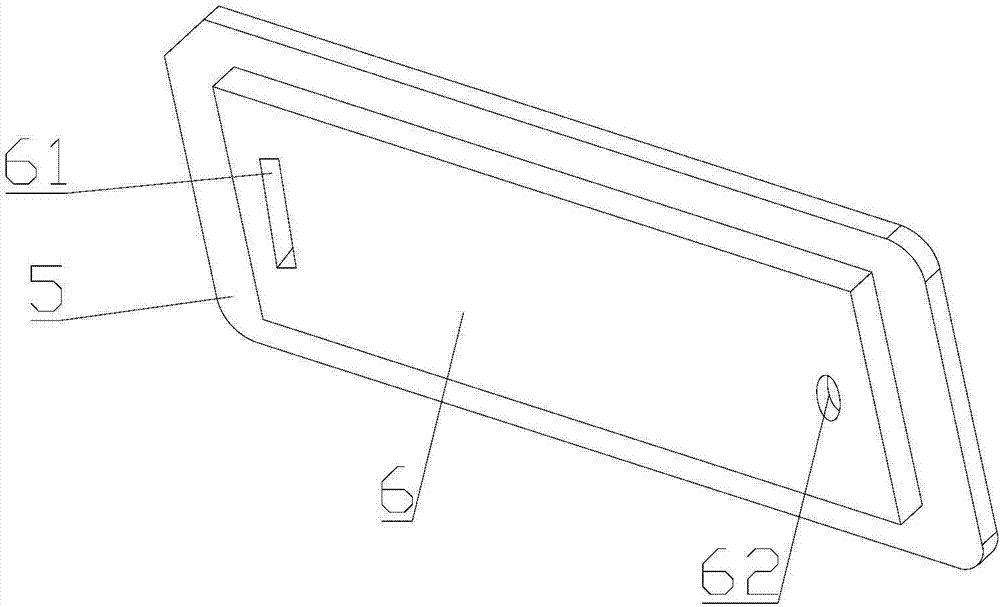

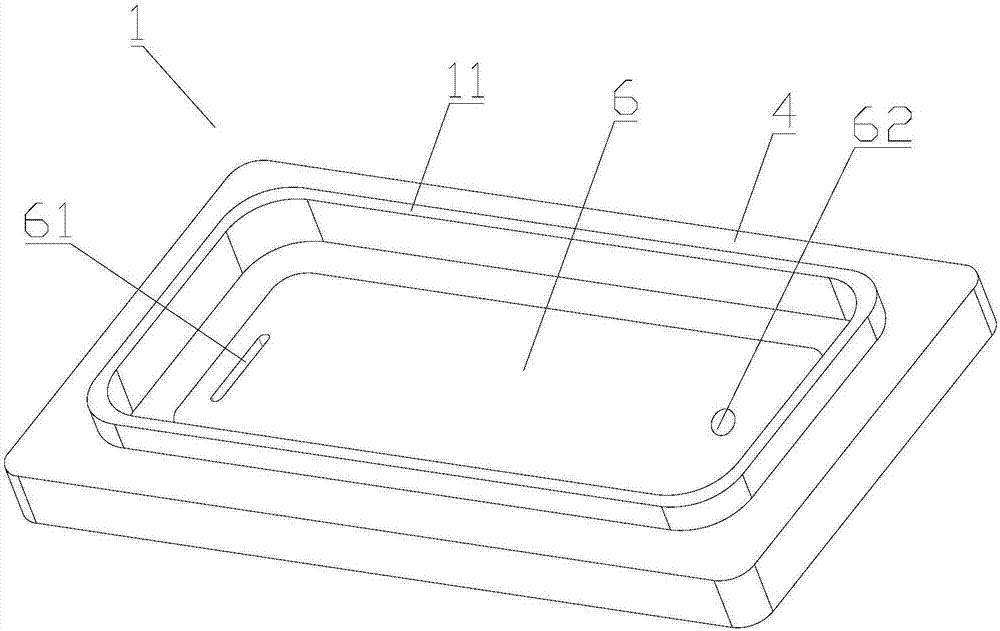

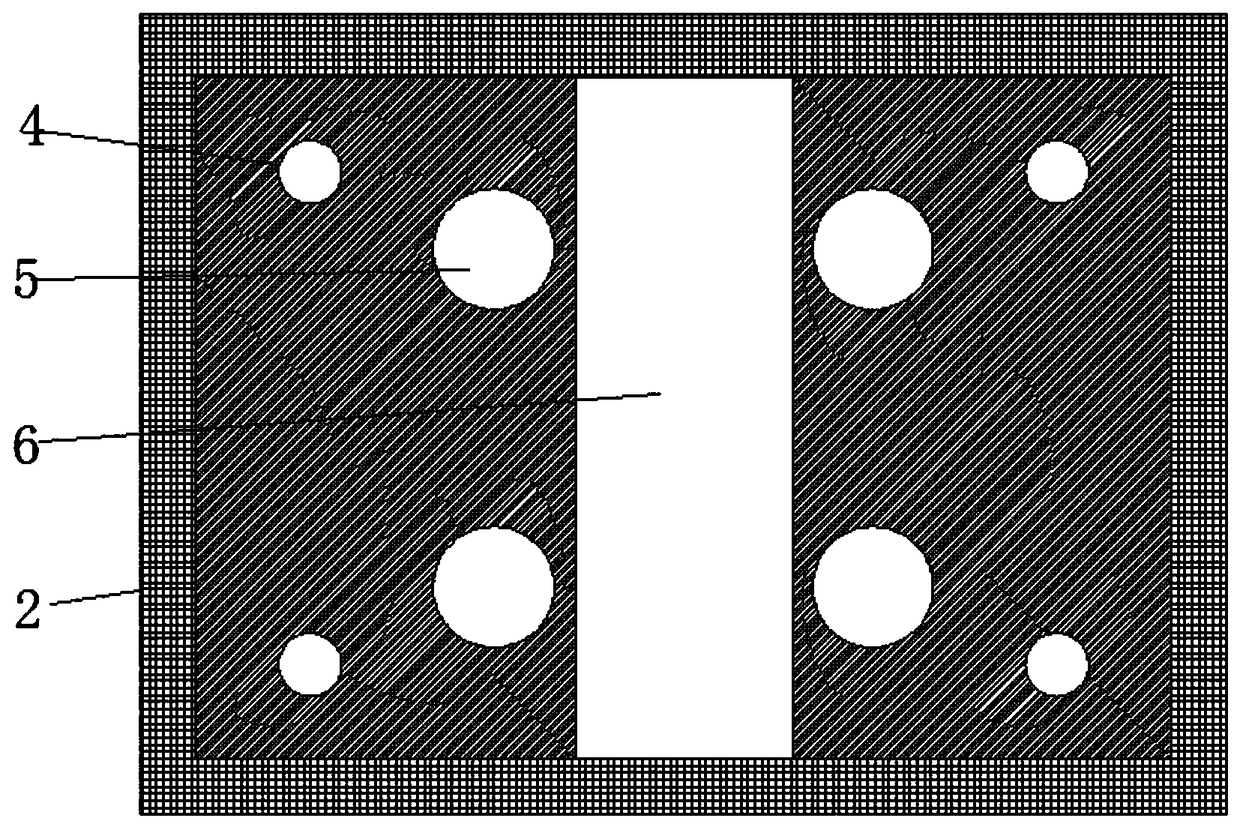

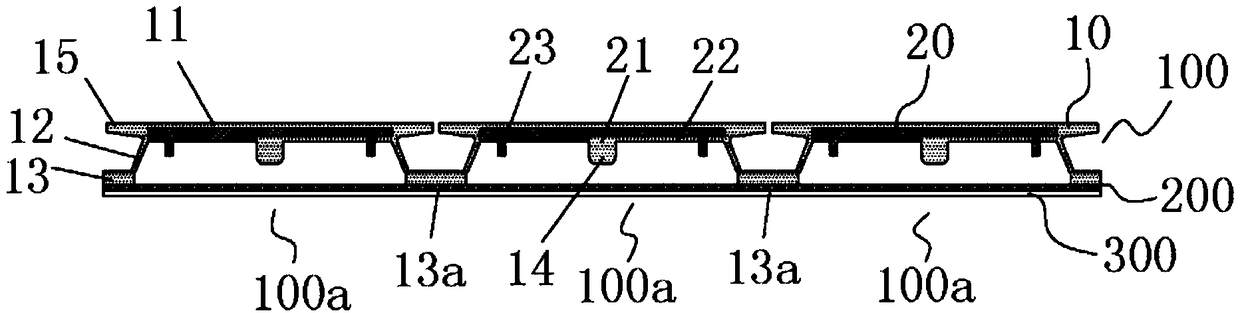

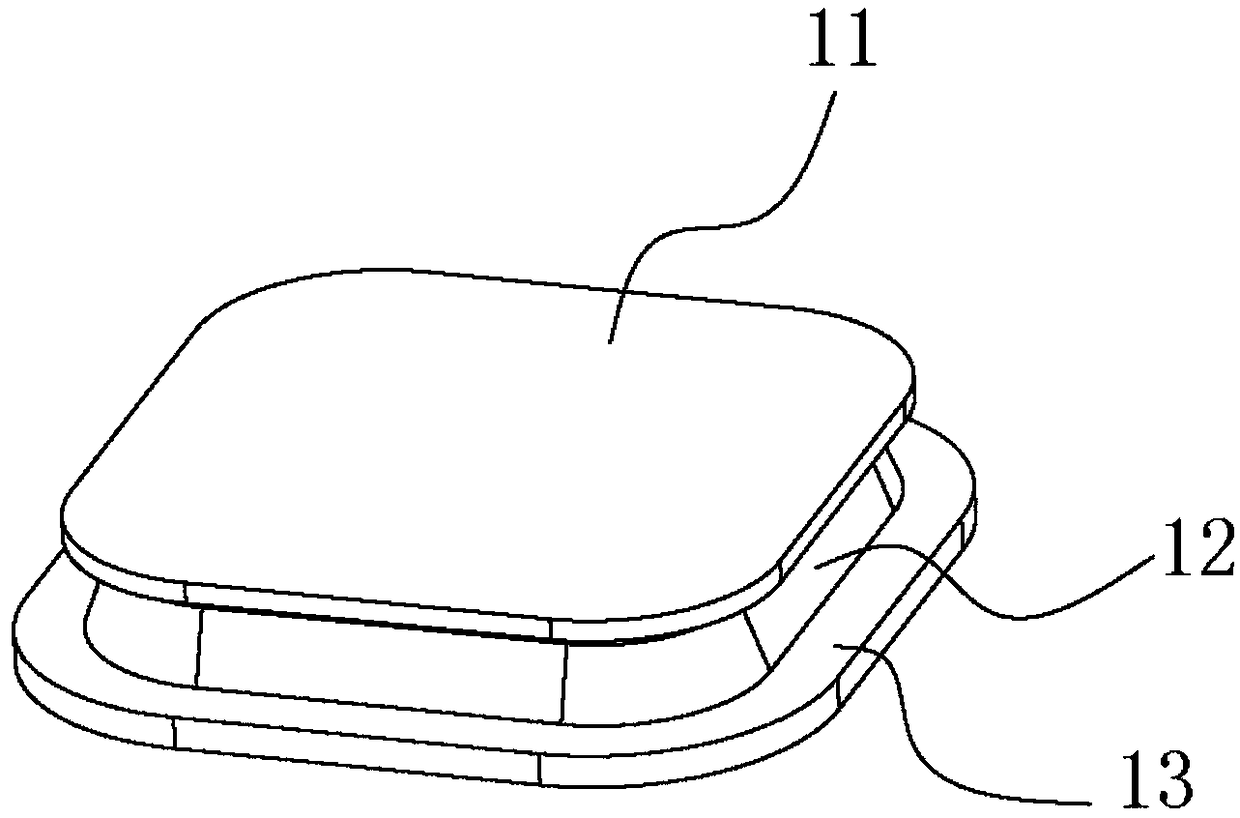

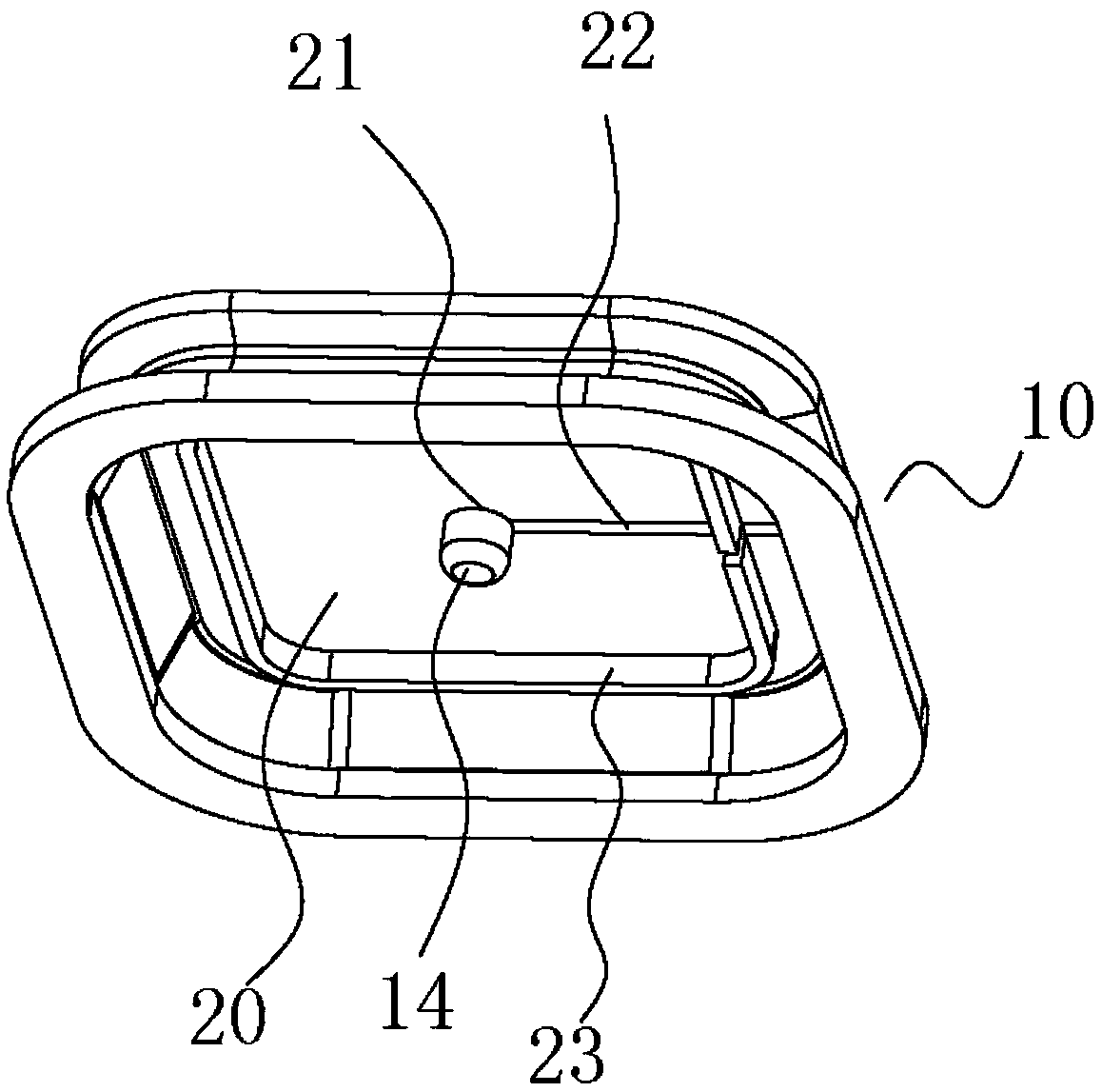

Mobile phone glass hot bending die

PendingCN106854035AReduce generationPrecise positioningGlass reforming apparatusGlass productionEngineeringMobile phone

The invention provides a hot-bending mold for mobile phone glass, aiming at solving the problem of low processing precision of the existing hot-bending mold for mobile phone glass. A mobile phone glass hot bending mold, including an upper template, a lower template and an insert; the upper surface of the lower template is provided with a boss and a groove surrounding the boss; the lower surface of the upper template is provided with a The inner pressure frame; the size and shape of the outer wall of the pressure frame and the inner wall of the outer ring of the groove are the same; there is a gap between the inner wall of the pressure frame and the inner wall of the inner ring of the groove. When the press frame is inserted into the groove, it can be confirmed that the upper template and the lower template are aligned, which is convenient for positioning and improves the processing accuracy; once the offset between the upper template and the lower template exceeds the error range, the press frame cannot be inserted in the In the groove, the hot bending process of mobile phone glass cannot be completed, which can effectively reduce the generation of defective products.

Owner:于爱荣

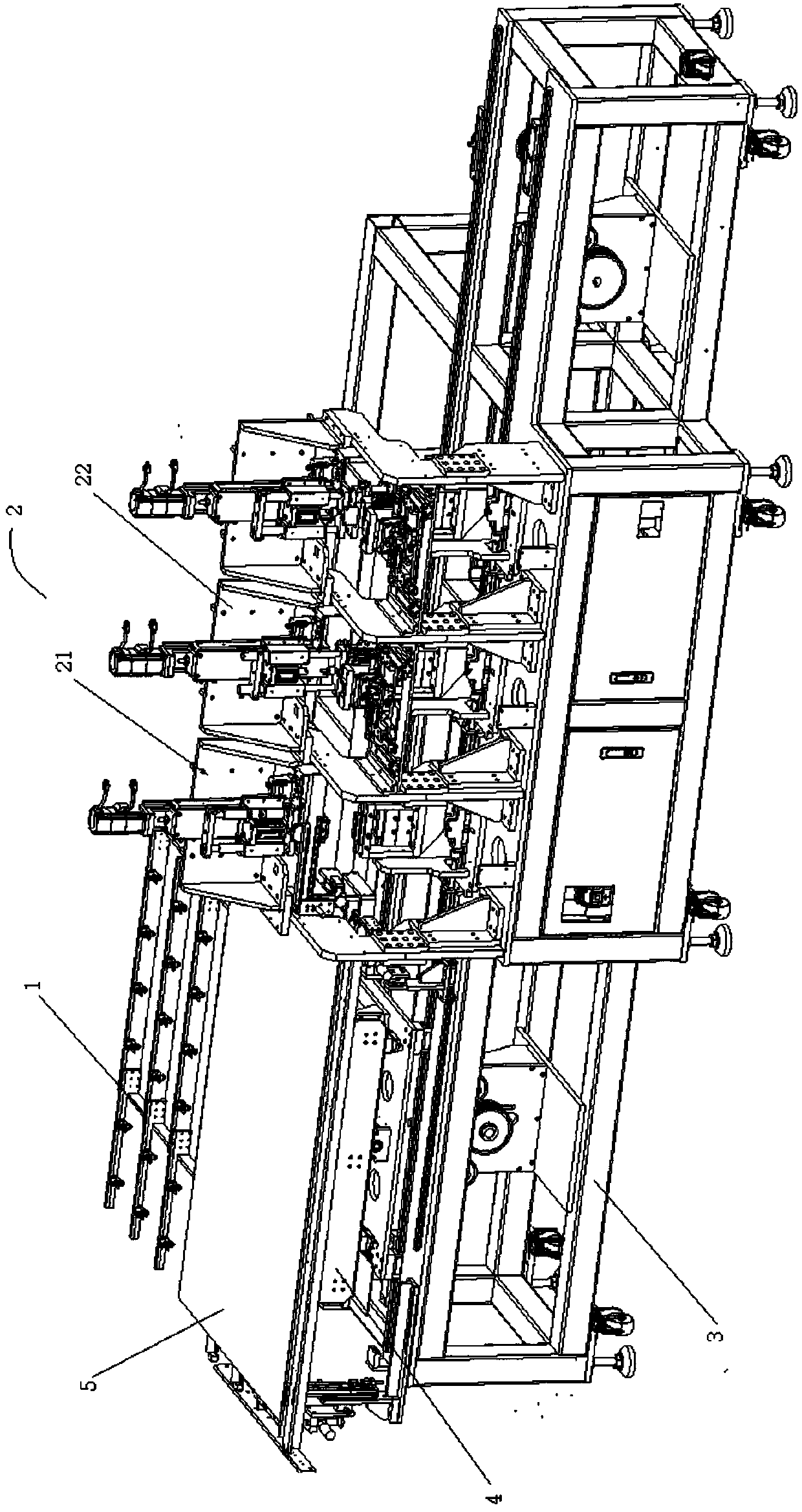

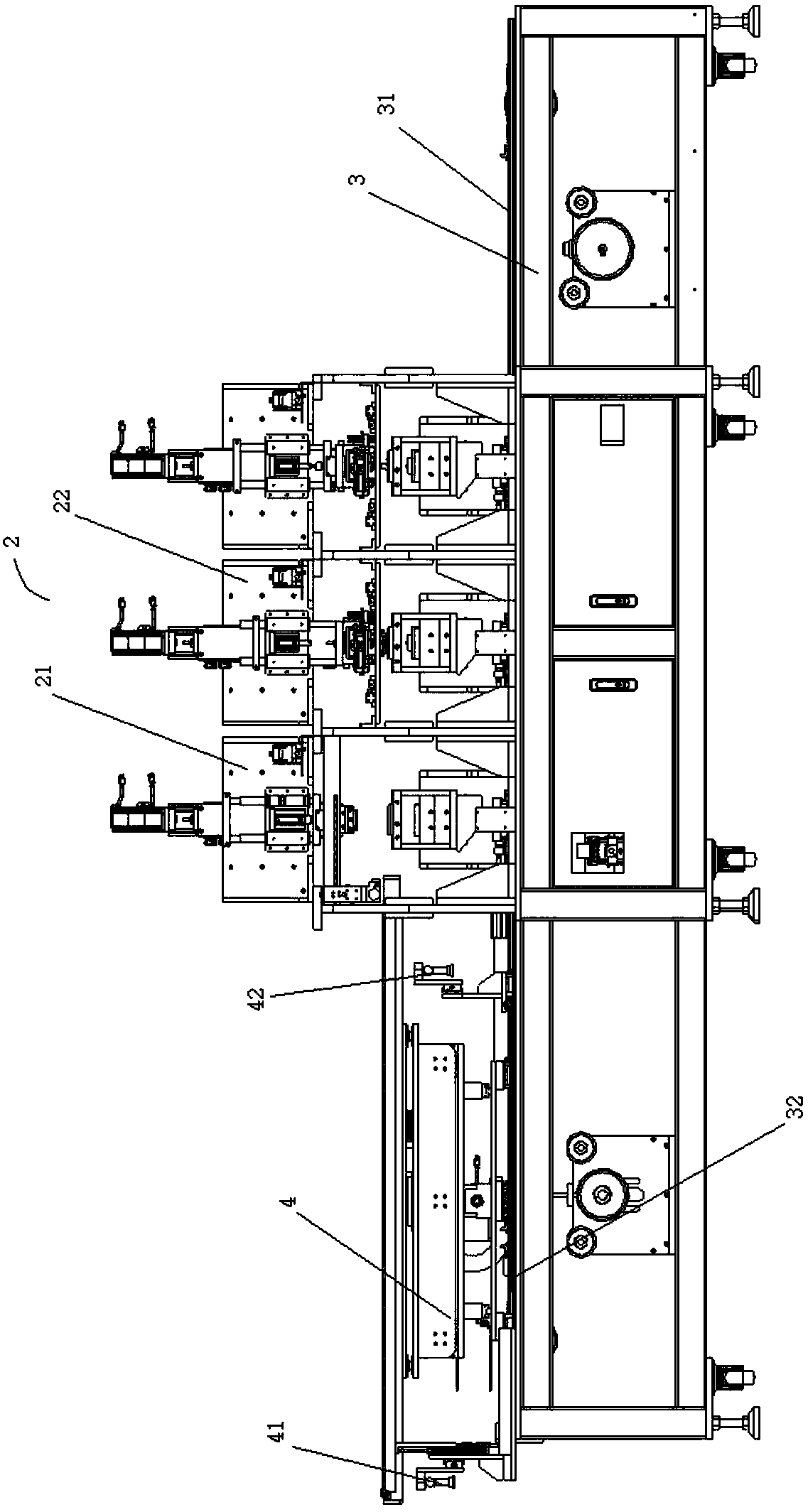

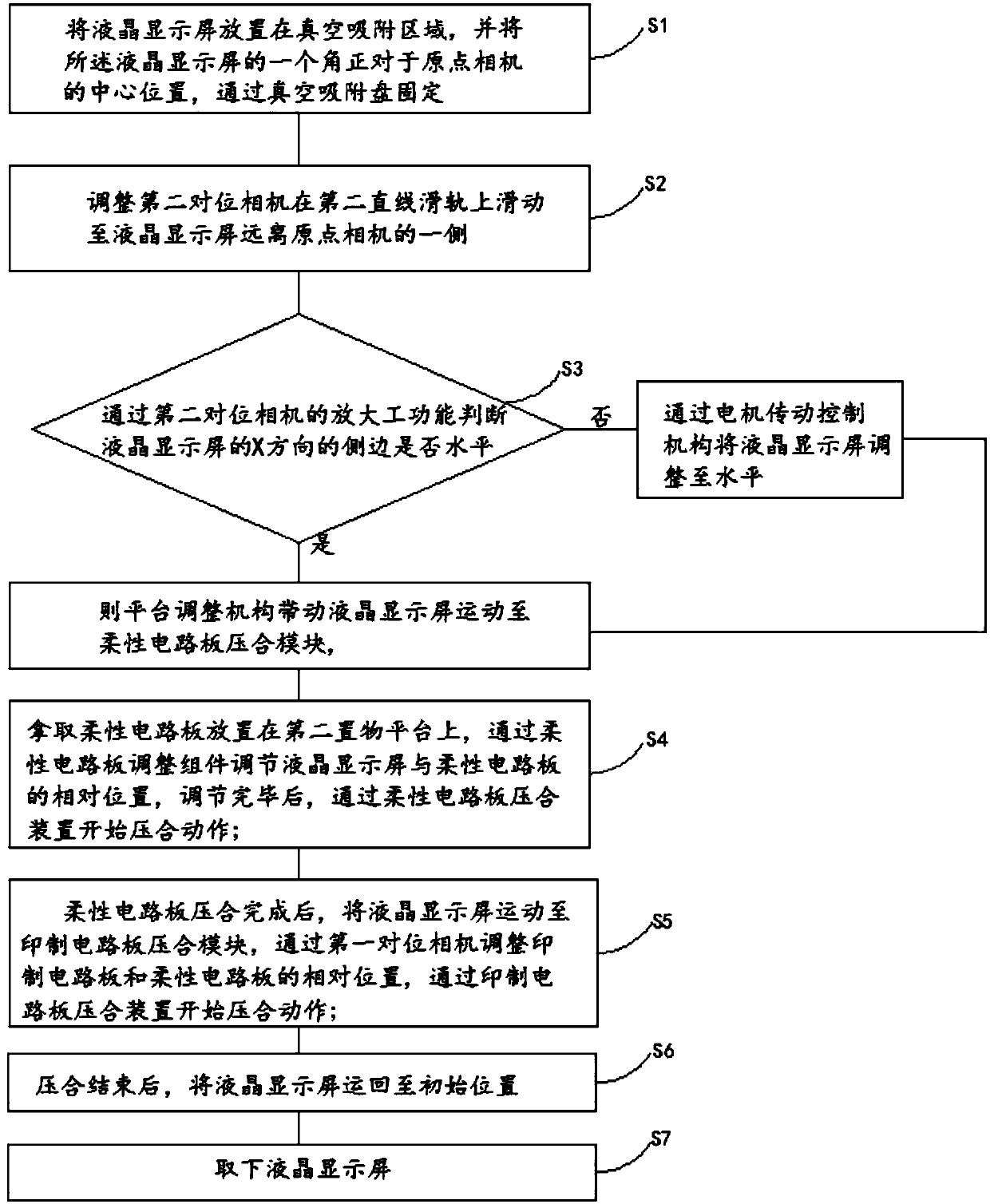

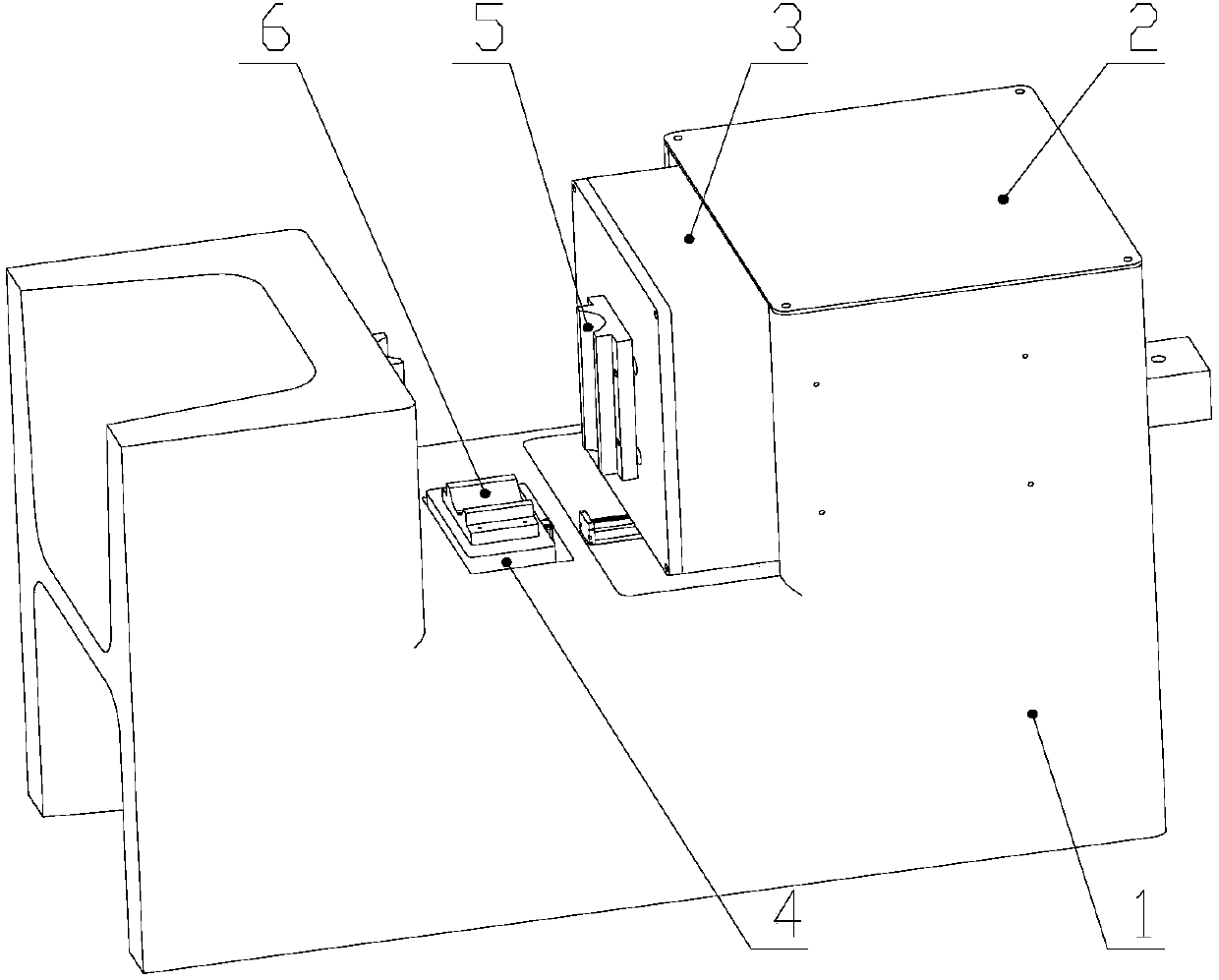

Liquid crystal display COF (chip on film) bonding semi-automatic device and pressing process thereof

ActiveCN107632424AAvoid bendingGuaranteed flatnessNon-linear opticsChip on filmLiquid-crystal display

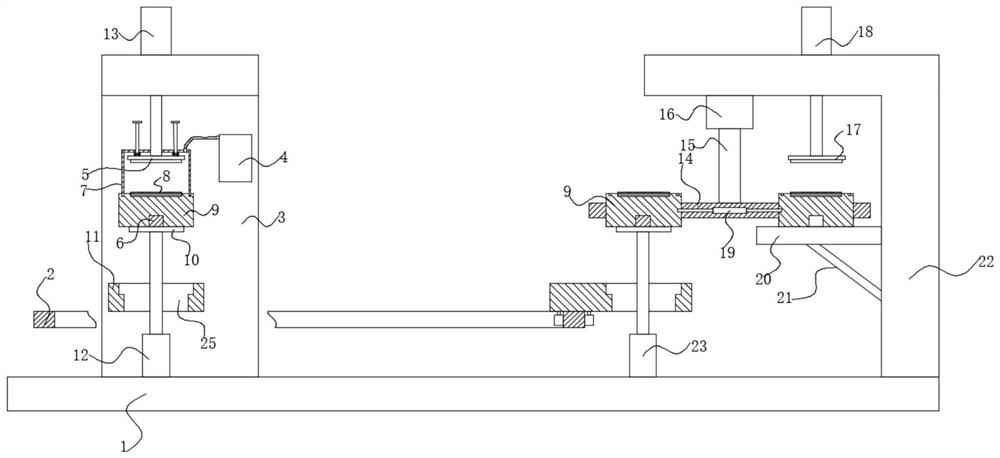

The invention relates to the technical field of liquid crystal display panel manufacture, and discloses a liquid crystal display COF (chip on film) bonding semi-automatic device which comprises a vacuum absorption mechanism and a pressing mechanism. A gravity center of the vacuum absorption mechanism approaches to one side of the pressing mechanism, flatness of large-size liquid crystal displays is ensured, and the pressing mechanism comprises a printed circuit board pressing module and a flexible printed circuit board pressing module. According to the device, straightness of printed circuit boards is monitored by a first alignment camera, relative positions of the liquid crystal displays and the printed circuit boards are adjusted by a second alignment camera and a motor transmission control mechanism, relative positions of the liquid crystal displays and flexible printed circuit boards are adjusted by a flexible printed circuit board adjusting component, the device solves the problems that a Gate side and a Source side are difficultly and simultaneously pressed, large-size liquid crystal displays are difficultly pressed when the flatness of the liquid crystal displays is ensured,and position accuracy is difficultly ensured by manually adjusting the positions of the liquid crystal displays in the prior art.

Owner:苏州富强加能精机有限公司

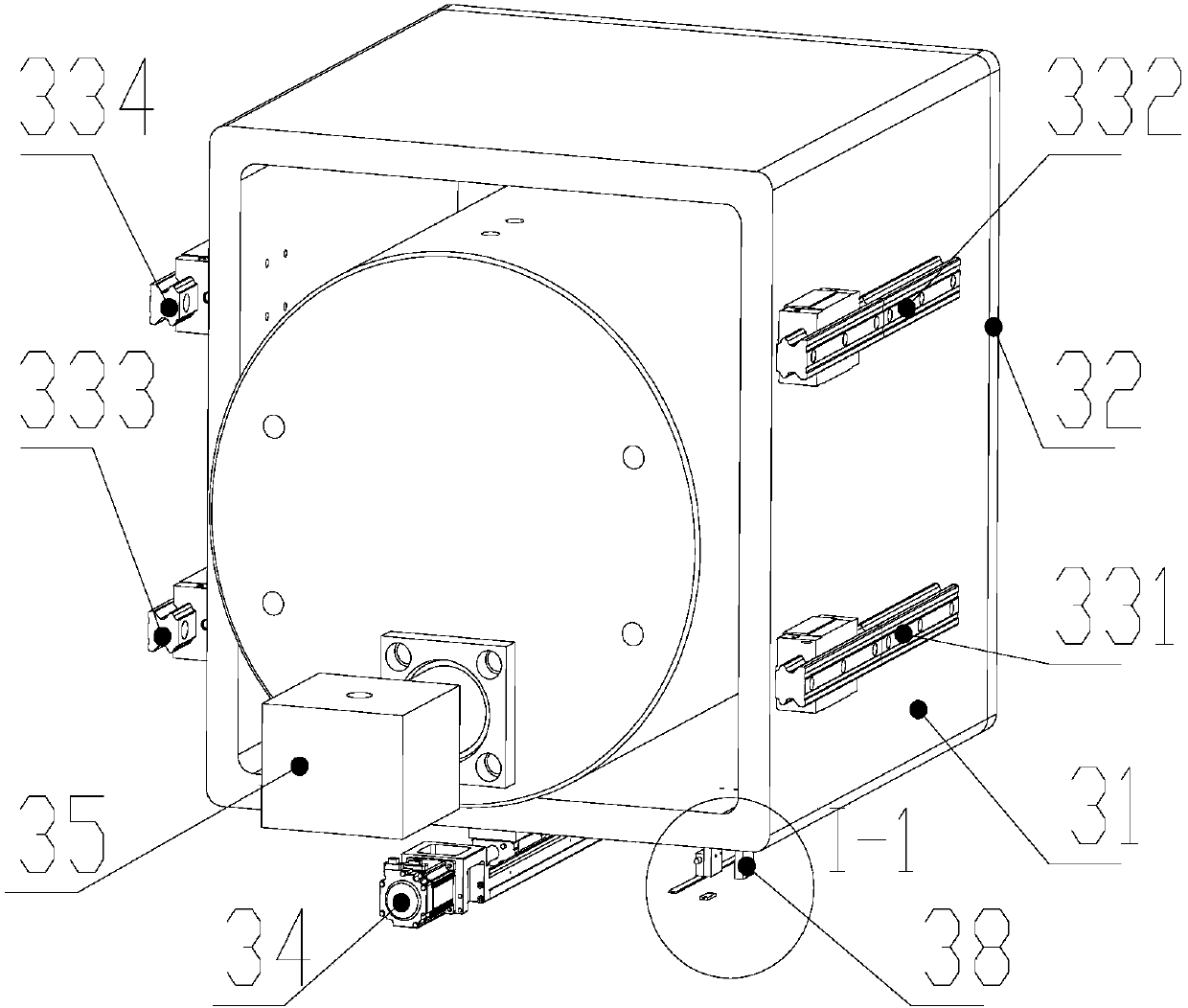

Full-automatic anchor chain gear pressing machine and gear pressing method

ActiveCN107932033AFlexible operationShorten the timeMetal working apparatusHydraulic cylinderStructural engineering

The invention discloses a full-automatic anchor chain gear pressing machine. The full-automatic anchor chain gear pressing machine comprises a machine body; the machine body is provided with a gear pressing mechanism and an anchor chain support structure; a transverse clamping fixture is arranged on the gear pressing mechanism; a longitudinal clamping fixture is arranged on the anchor chain support structure; the gear pressing mechanism comprises a gear pressing box, a gear pressing cover mounted on the gear pressing cover, a gear pressing linear module, a hydraulic cylinder, a magnetic railing ruler, a first proximity switch and a U-shaped mounting frame; the gear pressing box is positioned on the machine body; a hydraulic cylinder is positioned in the gear pressing box; a piston of the hydraulic cylinder is connected with the gear pressing cover; the transverse clamping fixture is mounted on the gear pressing cover; a reading head of the magnetic railing ruler is connected with the U-shaped mounting frame; and a magnetic bar of the magnetic railing ruler is mounted on the machine body. An anchor chain gear pressing displacement coordinate system is built through the magnetic railing ruler and the proximity switch; the position of the proximity switch is a zero point; the magnetic railing ruler acquires displacement values in real time for effective monitoring; a linear sliderail is used for guiding the gear pressing process with high precision; and fast forward and fast backward, and work forward and work backward of the piston of the hydraulic cylinder are effectively realized by adopting cooperation driving between the hydraulic cylinder and the linear module.

Owner:JIANGSU UNIV OF SCI & TECH

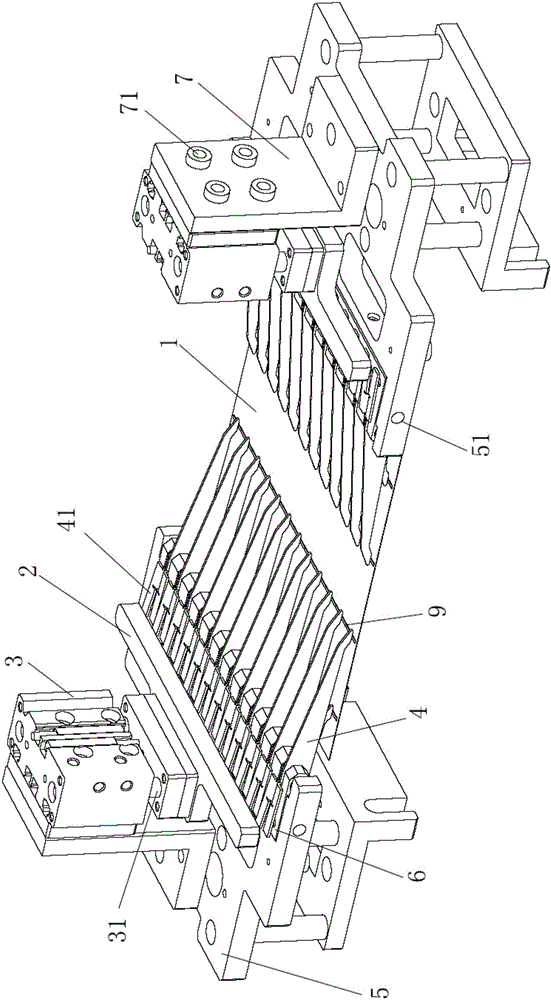

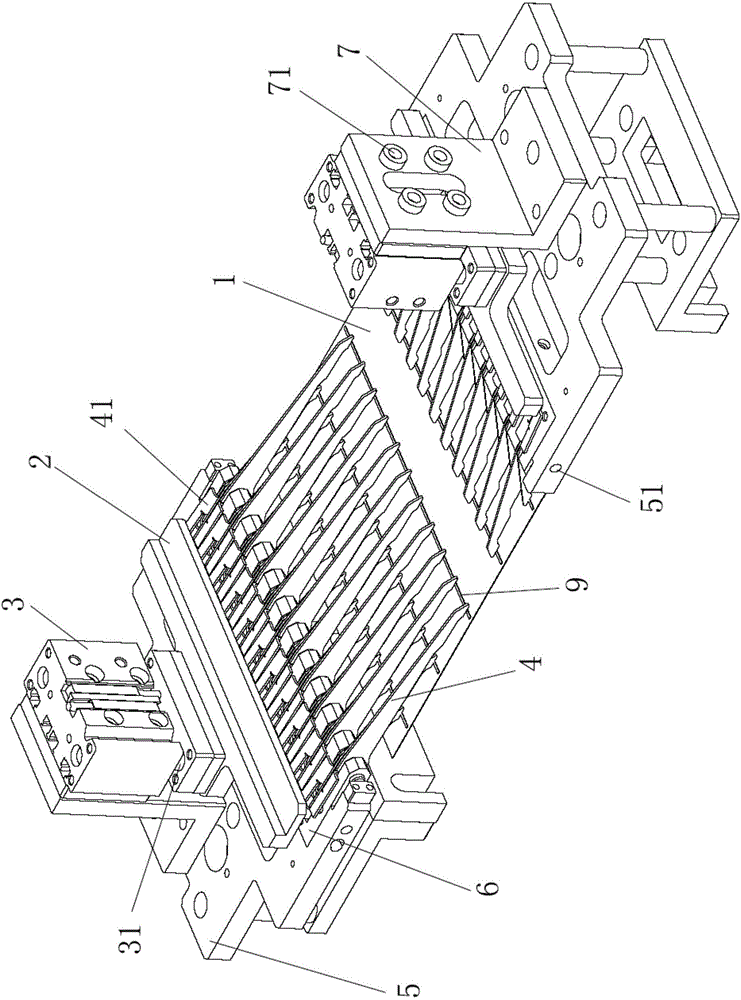

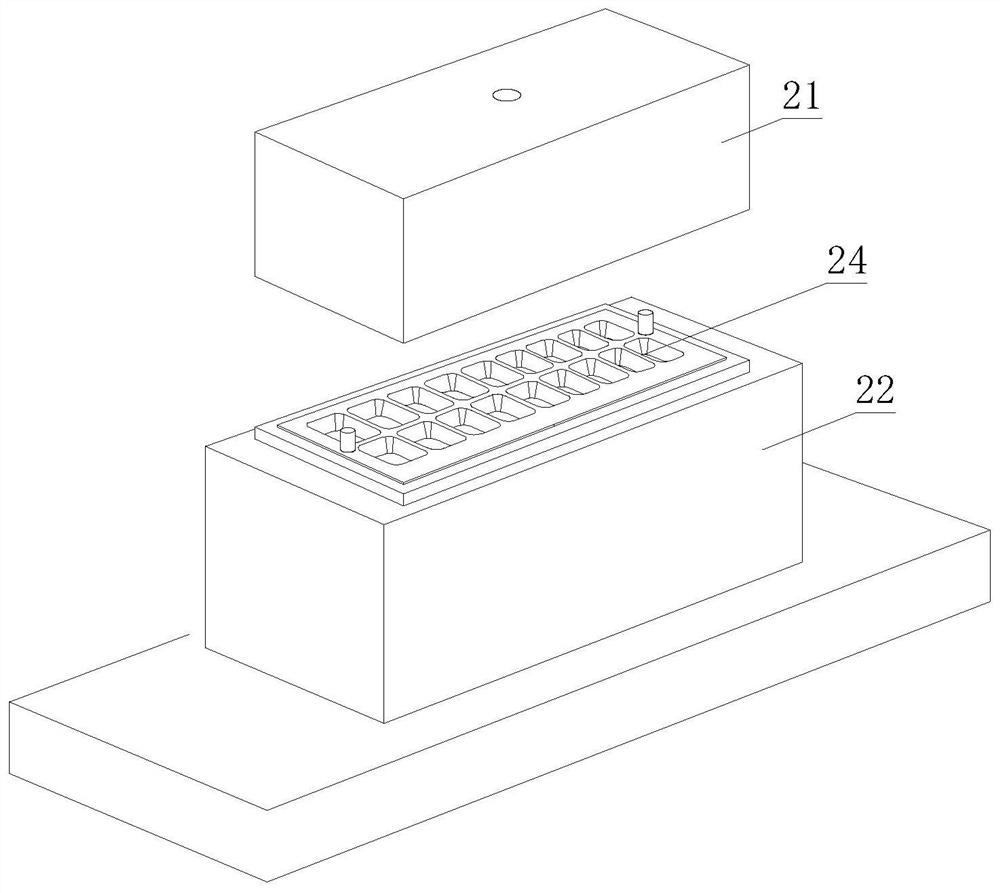

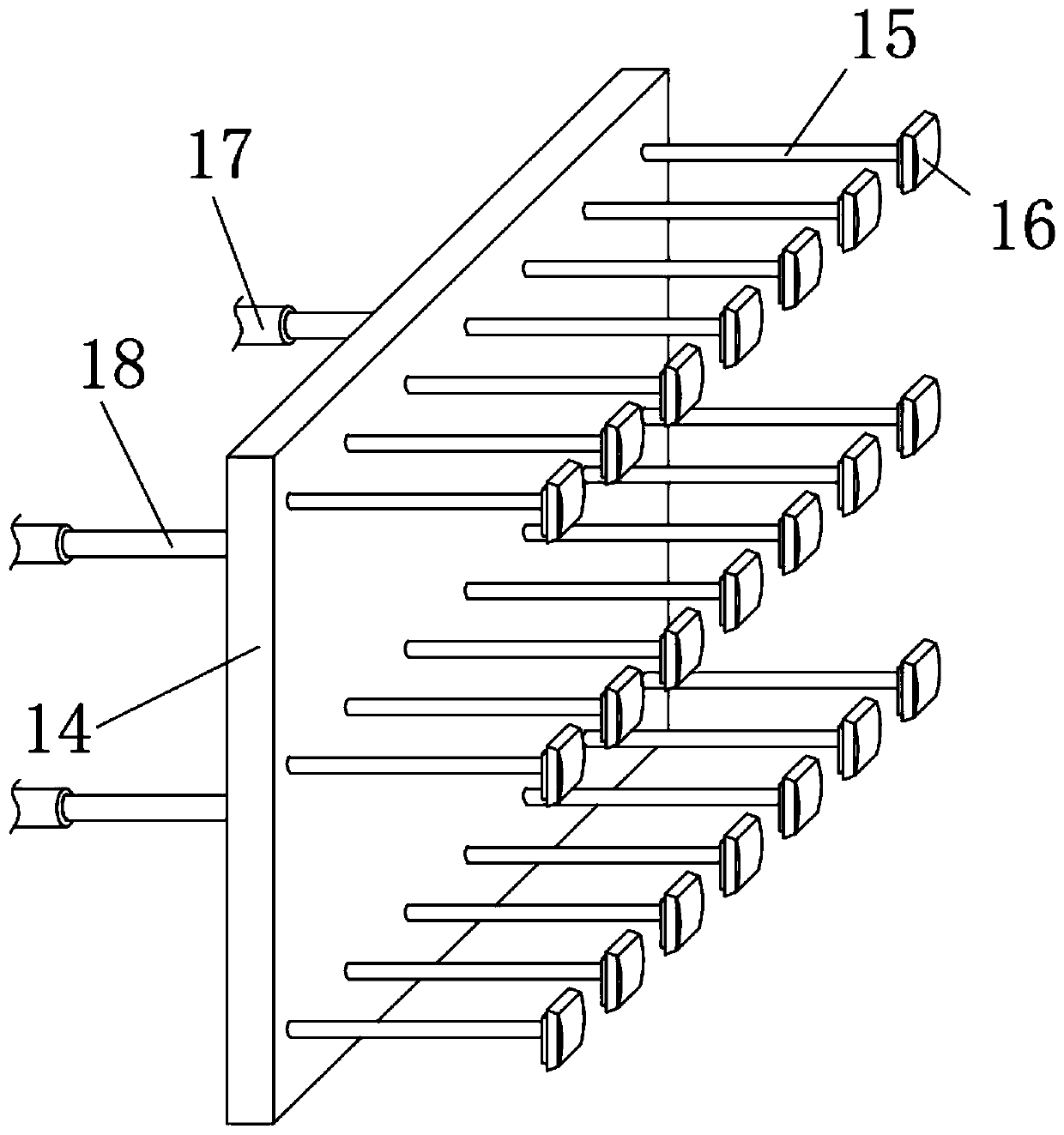

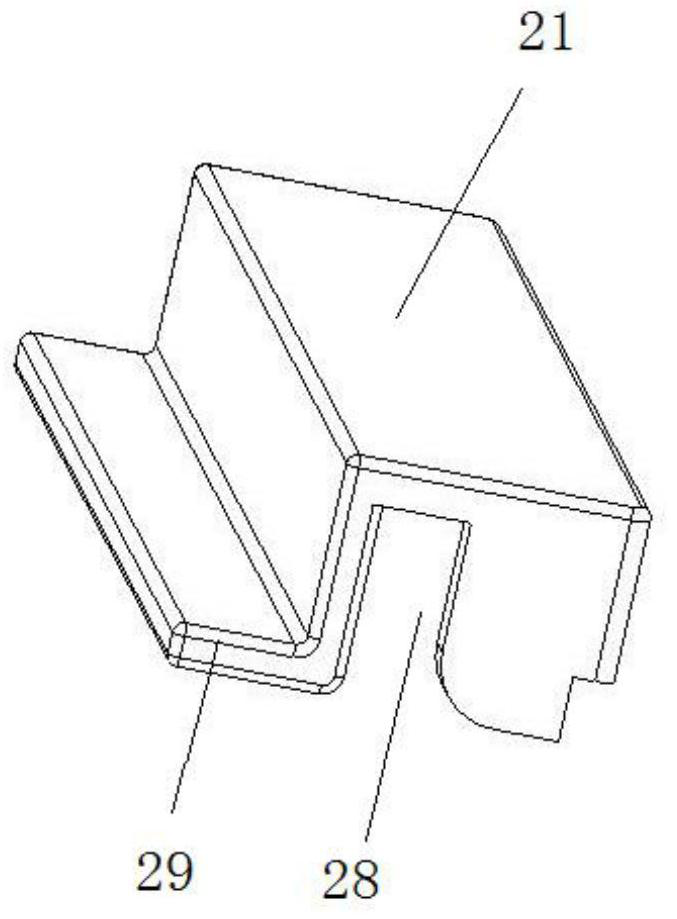

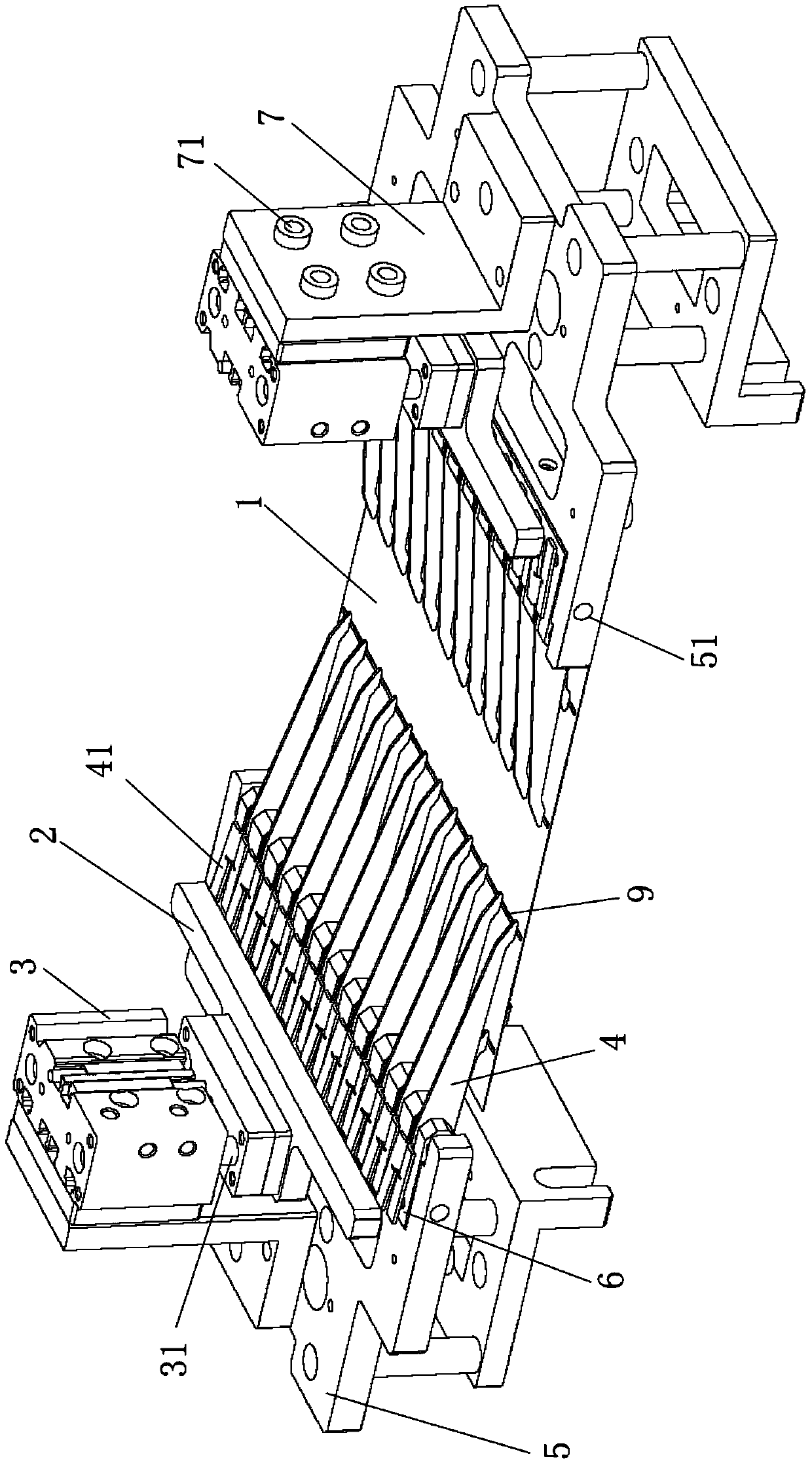

Novel pressing claw device

ActiveCN105522309AImprove welding qualityEven by forceFinal product manufactureWelding/cutting auxillary devicesWaste managementWelding

The invention discloses a novel pressing claw device. The novel pressing claw device comprises a pressing plate, a drive part driving the pressing plate, a plurality of pressing claws located under the pressing plate, a foundation base for bearing the parts and an installation base connected to the foundation base; installation parts for installing the pressing claws are arranged on the installation base at intervals, and an installation gap is formed between every two adjacent installation parts; convex installation plates are arranged on the tails of the reverse sides of the installation parts at intervals and are located on the joints between the installation parts and the installation gaps, and a concave installation plate is formed between every two adjacent convex installation plates; clamping and connecting elements are arranged at the tails of the pressing claws and are clamped from the installation gaps; one installation gap is connected to one or two pressing claws in a clamping mode, and the clamping and connecting ends of the clamping and connecting elements are placed on the convex installation plates or the concave installation plates; the pressing claws are connected to the installation parts in a rotating mode. According to the novel pressing claw device, the pressure welding position is more accurate, the pressing strength is more appropriate, the compatibility is high, the requirements of pressure welding of battery pieces of various specifications can be met, and the product quality can be improved.

Owner:SUZHOU AUTOWAY SYST

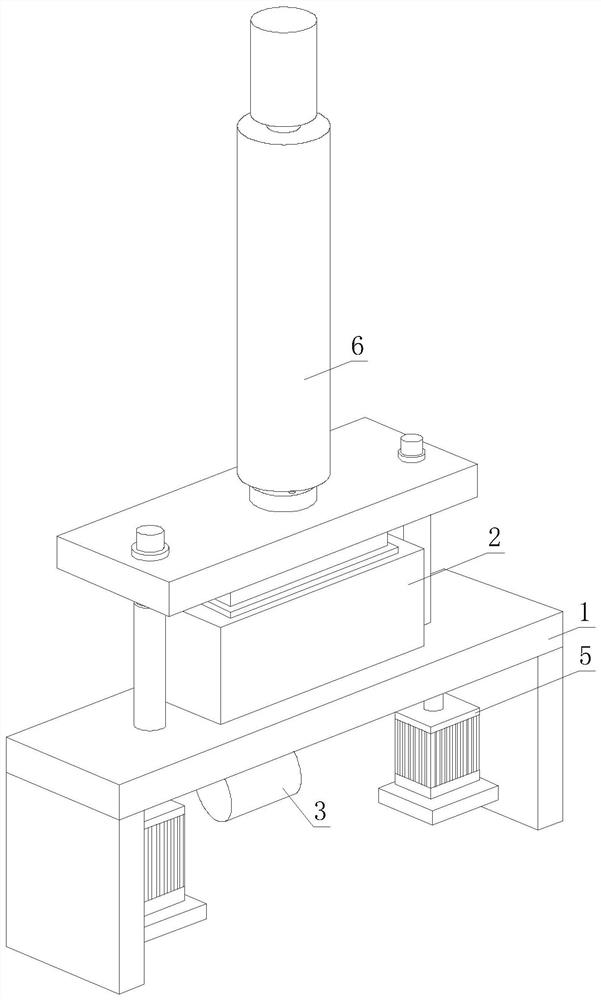

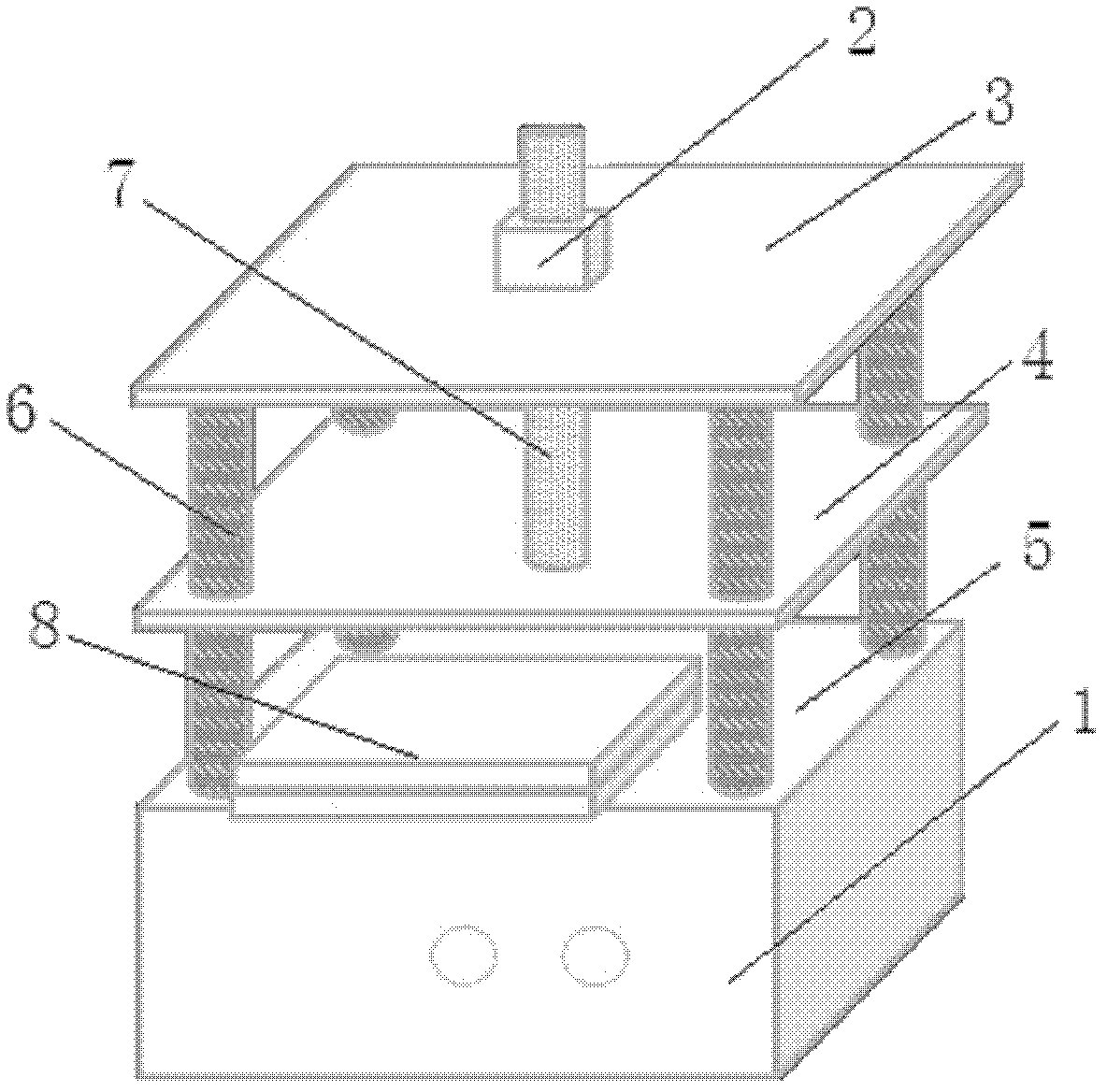

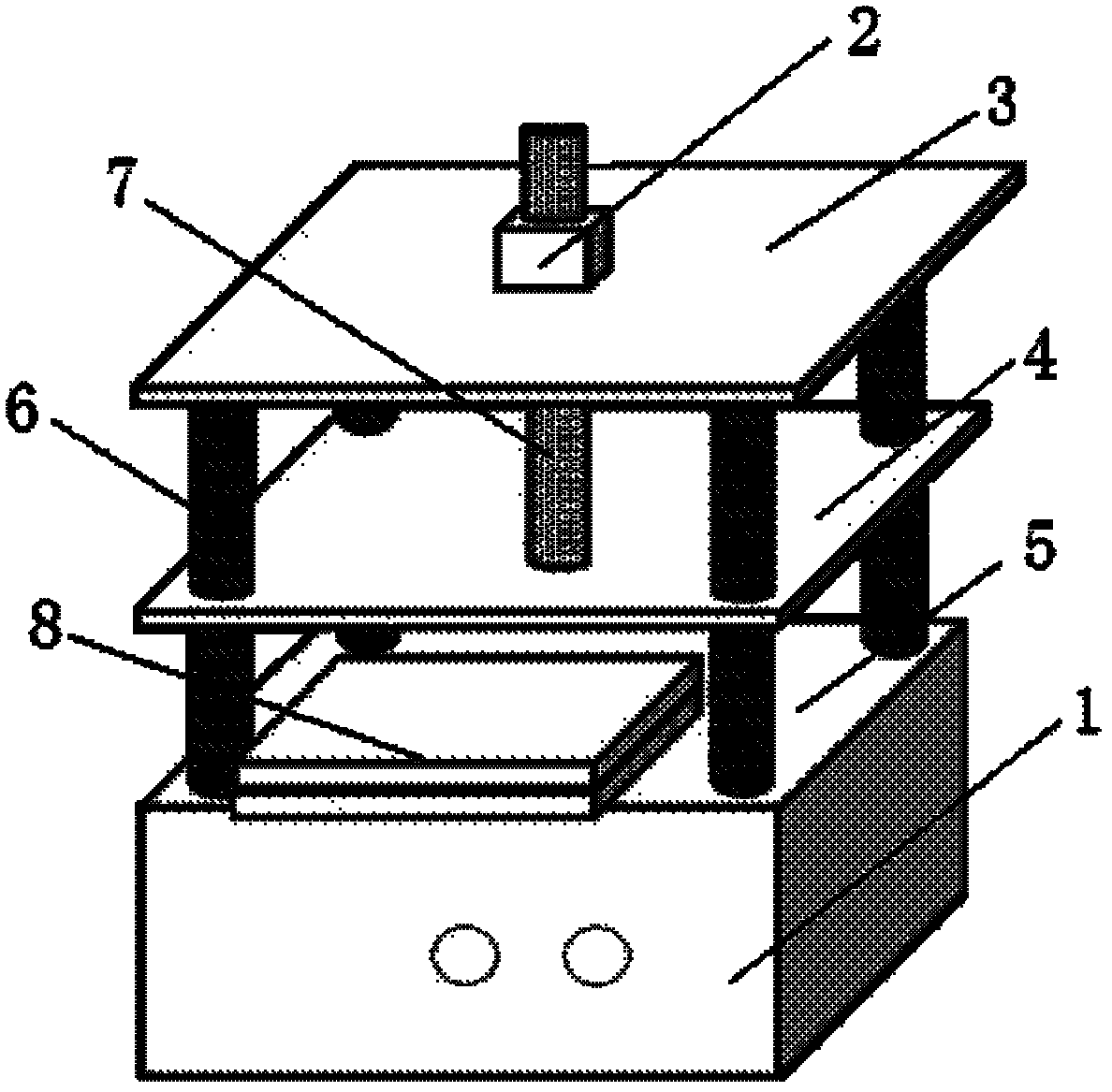

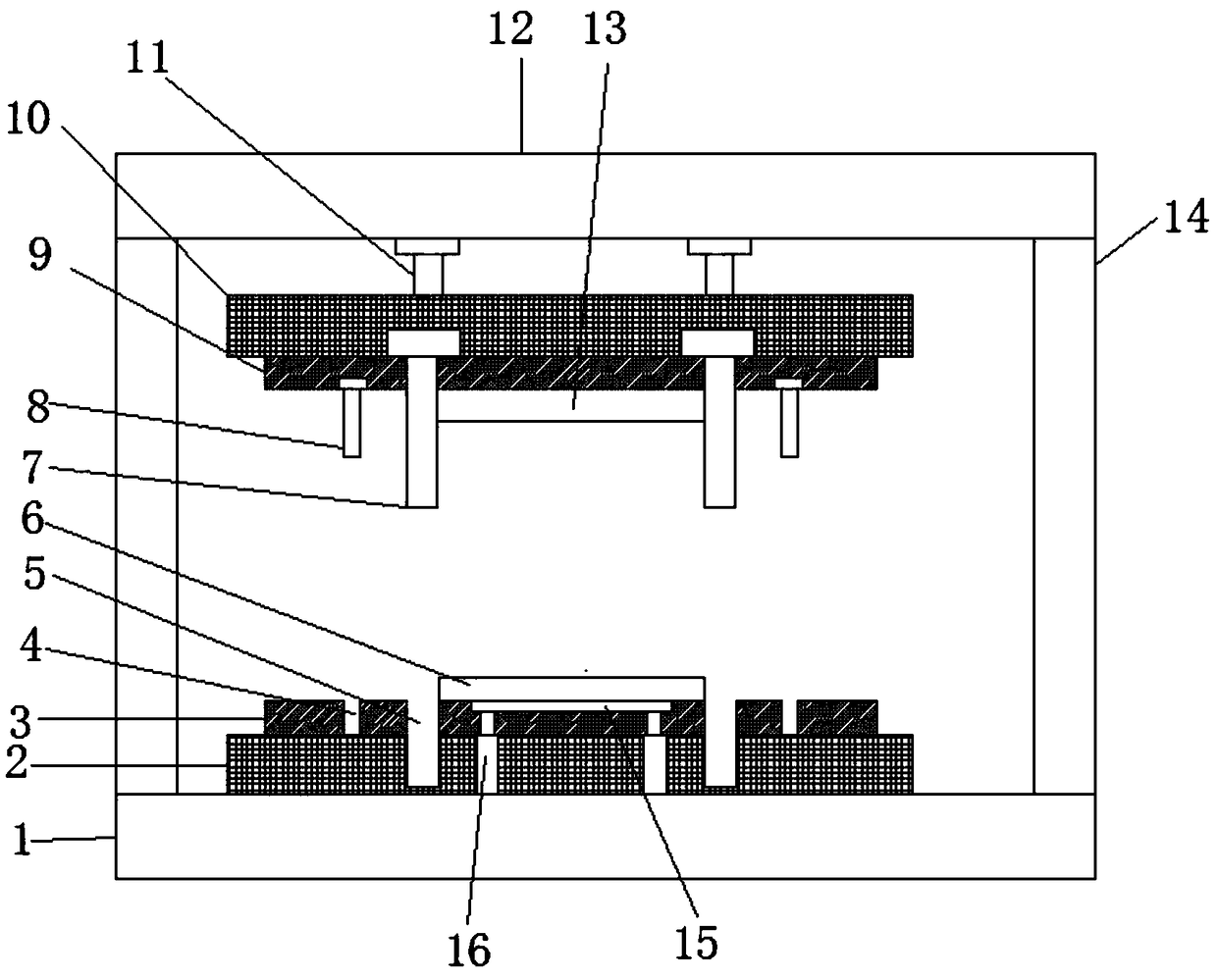

Forming curing mold for plastic-sealed diode production and implementation method of forming curing mold

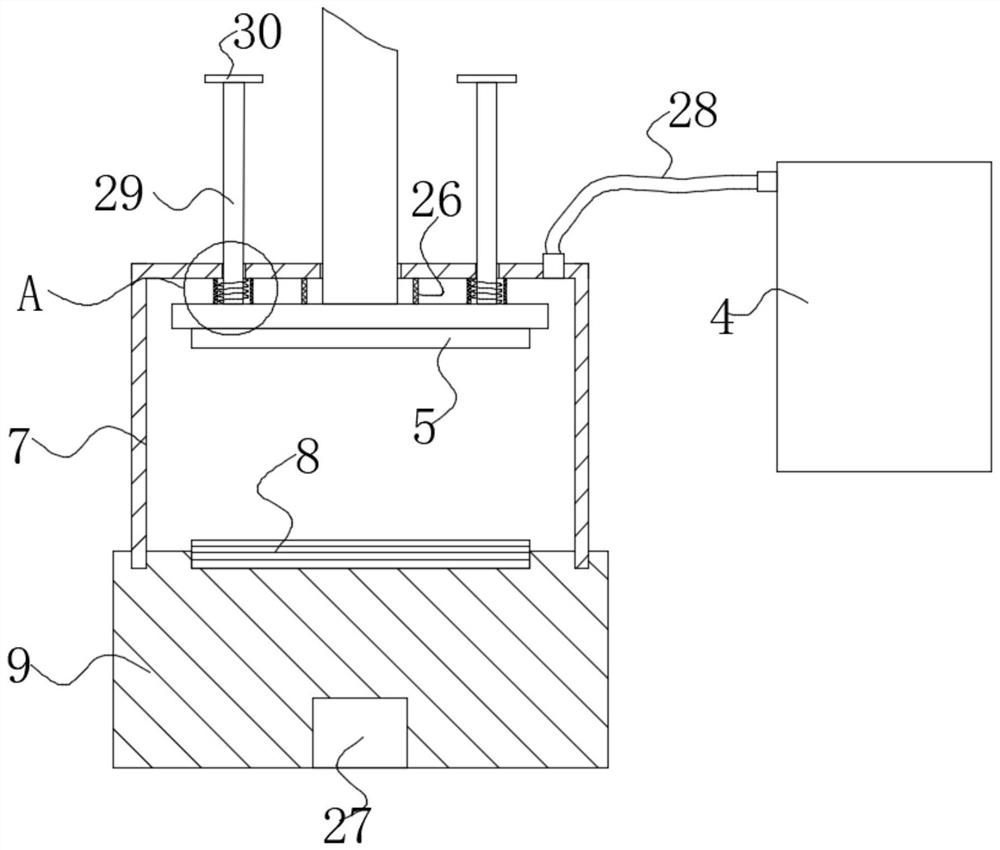

InactiveCN113085098AEasy to placeEffective placementDomestic articlesInjection molding processMechanical engineering

The invention discloses a forming curing mold for plastic-sealed diode production and an implementation method of the forming curing mold, and belongs to the technical field of plastic-sealed diode production. The forming curing mold comprises a base, wherein a curing mold assembly is arranged above the base, a demolding ejection assembly is arranged on the lower portion in the curing mold assembly, a cooling assembly is arranged in the curing mold assembly, a power assembly is connected to the upper portion of the curing mold assembly, and an injection molding assembly is connected to the upper portion of the power assembly above the curing mold assembly. According to the forming curing mold for plastic-sealed diode production and the implementation method of the forming curing mold, injection molding liquid is prevented from leaking, the quality of plastic-sealed objects is improved, the demolding efficiency is improved, the inconvenience of manual demolding is reduced, and the effect of rapid curing is achieved; water resource waste is reduced through circular cooling, and the cooling efficiency is also greatly improved; and the mechanical energy of an upper mold base is effectively guided, the pressing precision is improved, the joint closing efficiency is guaranteed, the injection molding efficiency is improved, the situation that internal liquid solidifies to block an inner groove in the next injection molding process can be avoided, and the dredging efficiency is improved.

Owner:赣龙微电子科技(定南)有限公司

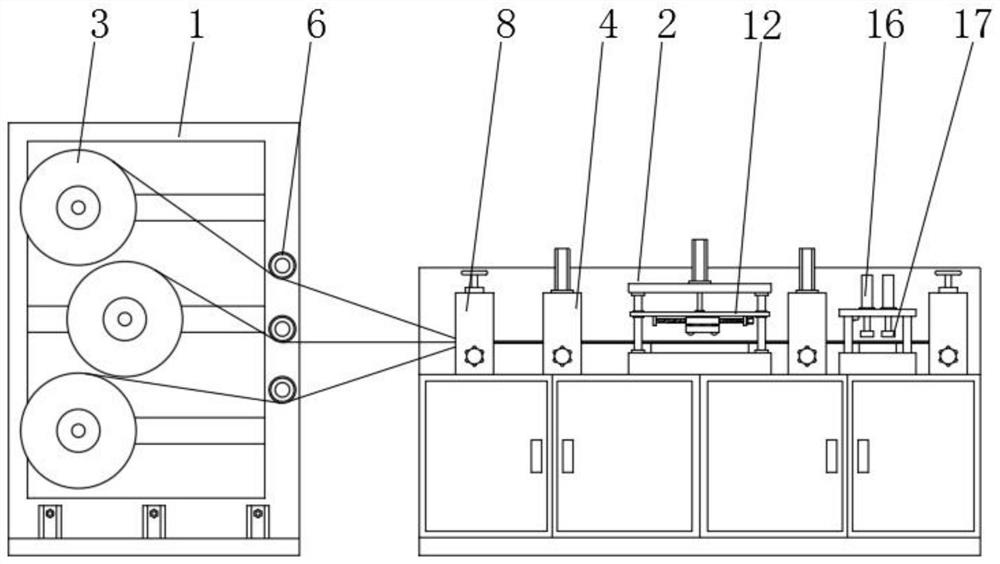

Laminating and pressing device for mask production

InactiveCN111838856APrevent back and forth shakingImprove pressing accuracyProtective garmentClothes making applicancesEngineeringMechanical engineering

The invention discloses a laminating and pressing device for mask production. The device comprises a placement frame and a press-fit table, a plurality of mask cloth placement rollers and a pluralityof cloth guide frames are arranged on the placement frame, the guide frames are located on sides of the mask cloth placement rollers, two cloth limiting frames and a press-fit device are arranged on the outer surface of the upper end of the press-fit table, and the press-fit device is located between the two cloth limiting frames; and the cloth guide frame comprises a mounting column, a sleeve andan arc-shaped piece. The invention discloses the laminating and pressing device for mask production, the position of cloth is limited, forward and backward shaking during cloth conveying is avoided;the cloth can be limited from the two ends and can be supported, so that the cloth is in a tensioned state, the shaking of the cloth is reduced, the pressed cloth is prevented from being separated, the pressing effect of the cloth is improved, the comprehensive pressing of the cloth is achieved, the pressing effect of the mask cloth is better, and a better use prospect is brought.

Owner:安徽美裕集团有限公司

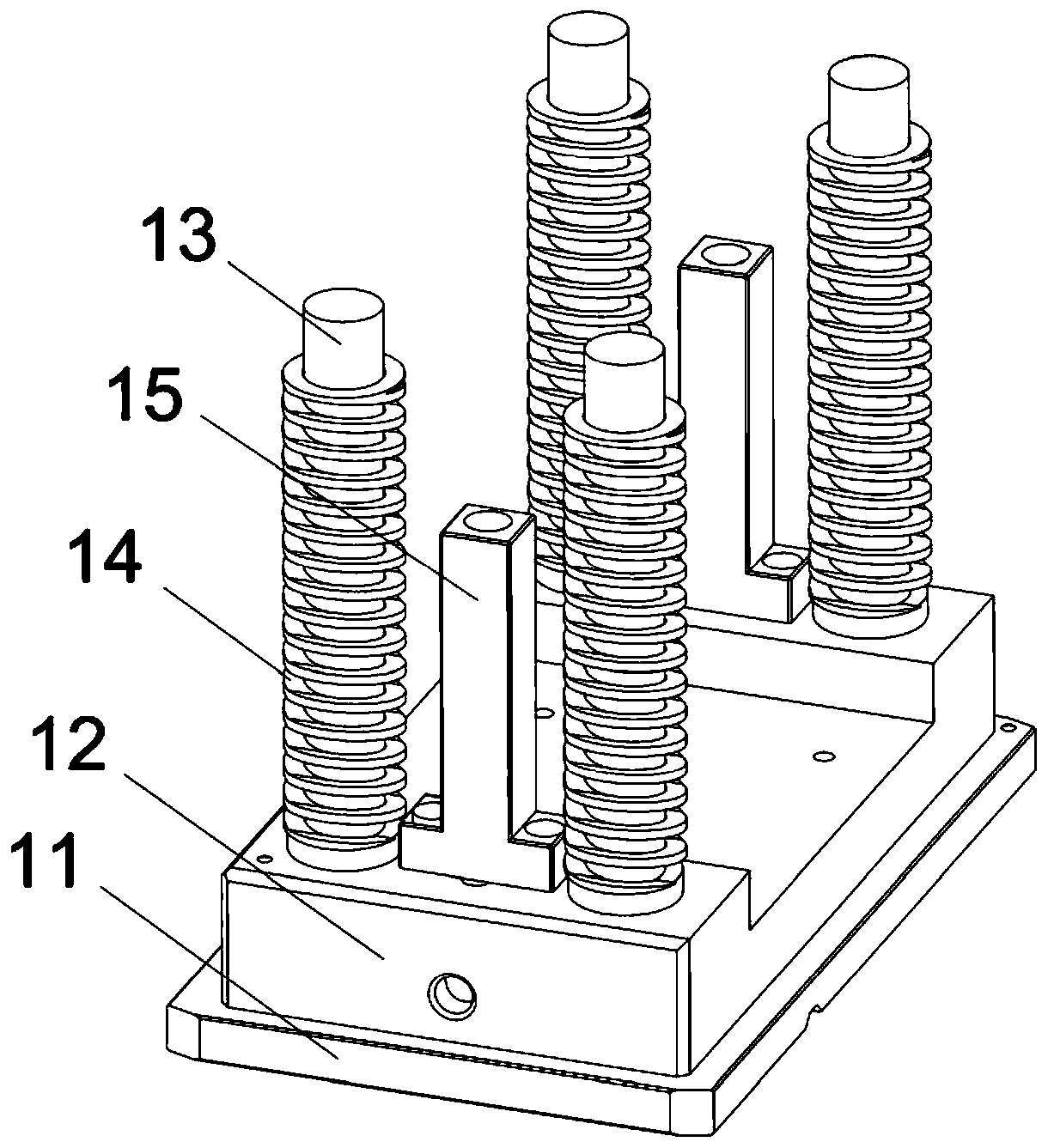

Precision pressing mechanism for ecological plate machining

ActiveCN110843054APlay a limiting effectImprove stabilityPlywood pressesVeneer pressesElectric machineryEngineering

The invention relates to the technical field of ecological plate machining, and particularly discloses a precision pressing mechanism for ecological plate machining. The mechanism comprises a worktable, a top plate and a putting plate, the center of the front face of the top plate is fixedly connected with a fixed table through a bolt, the front face of the bottom of the fixed table is fixedly connected with a fixed plate, a supporting plate is fixedly connected to the position, close to the bottom of the center, of the front face of the fixed plate, the center of the top of the supporting plate is fixedly connected with a sliding rail, the center of the front face of the sliding rail is fixedly connected with a stepping motor, the back face of a connecting block is fixedly connected witha push rod, the end, away from the connecting block, of the push rod penetrates through the back face of the fixed plate and is fixedly connected with a connecting plate, the position, corresponding to the putting plate, of the side, away from the push rod, of the connecting plate is fixedly connected with multiple connecting rods, and correction push blocks are fixedly connected to the ends, close to the putting plate, of the connecting rods. The correction push blocks can push the plate on the putting plate under the effect of the stepping motor, and the plate pressing precision can be improved effectively.

Owner:雪宝家居集团有限公司

Cell phone key pressing device

InactiveCN102646529AIncrease the pressing speedImprove efficiencyElectric switchesKey pressingEngineering

The invention discloses a cell phone key pressing device, which comprises a base and an extrusion device. A working table for placing cell phone keys is arranged on the base. The cell phone key pressing device is characterized by further comprising a top plate and a pressing plate. A guiding track is arranged on the working table, the guiding track penetrates through the pressing plate, the pressing plate can move along the guiding track vertically, the top plate is arranged on top of the guiding track, the extrusion device is arranged on the top plate, and a pressing rod of the extrusion device penetrates through the top plate to be connected with the top of the pressing plate. The cell phone key pressing device solves the problems that in the prior art keys and rubber are pressed manually, pressing speed is slow, efficiency is low, precision is poor, defective rate of products is high, and production cost of enterprises is high are solved. The cell phone key pressing device is simple in structure, low in production cost, and capable of pressing plastic keys and rubber fast, accurately and safely.

Owner:昆山威茂电子科技有限公司

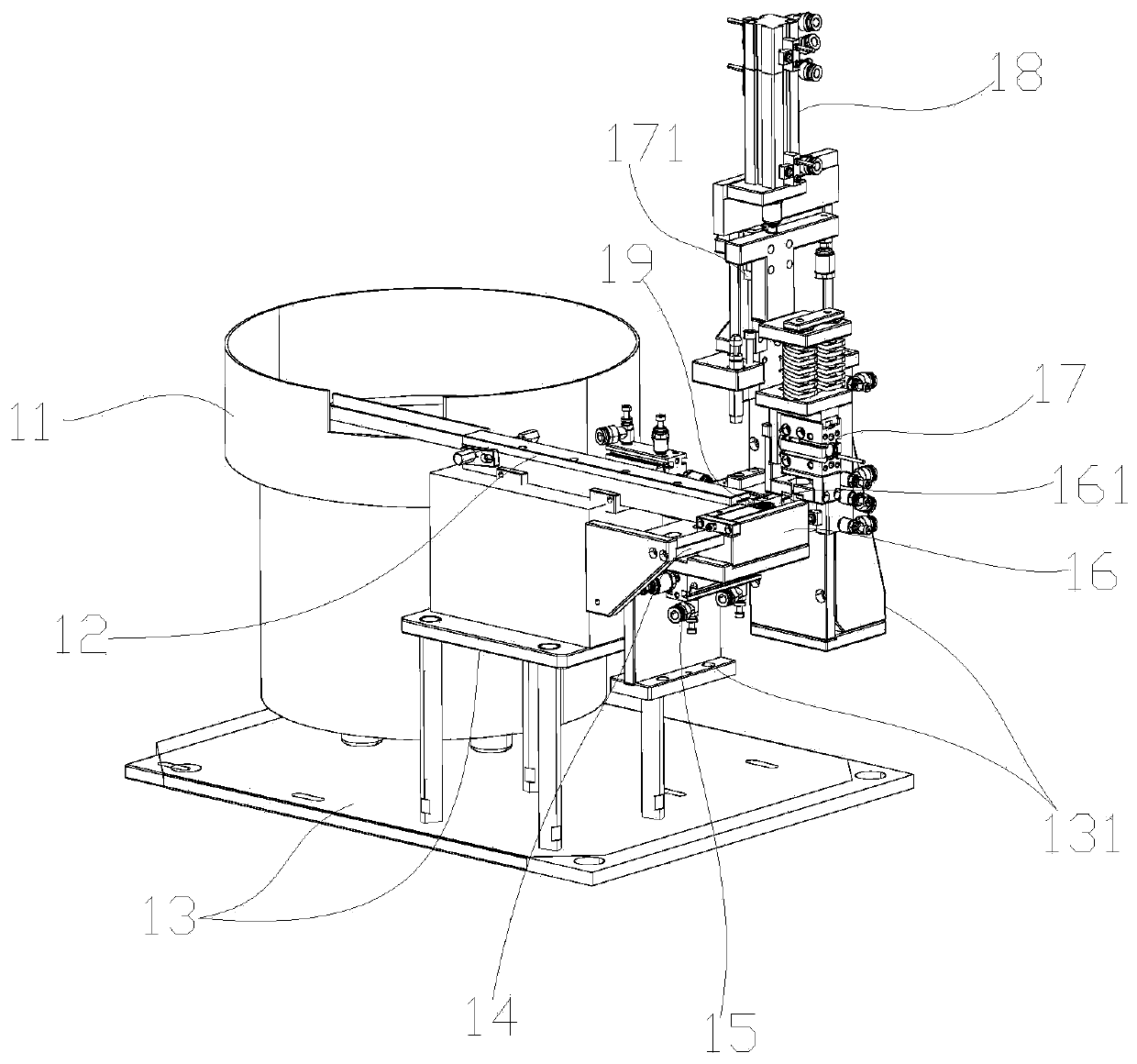

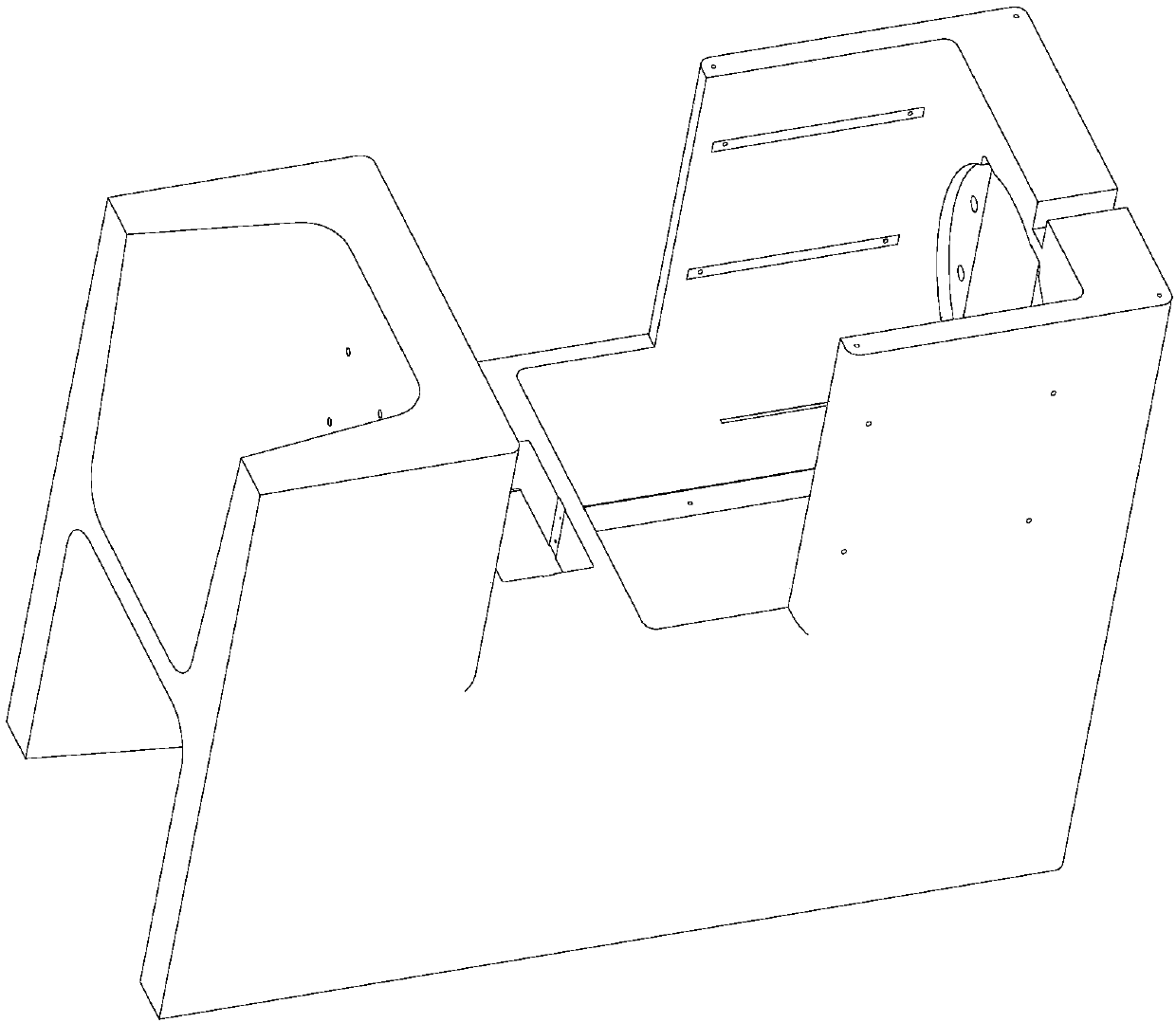

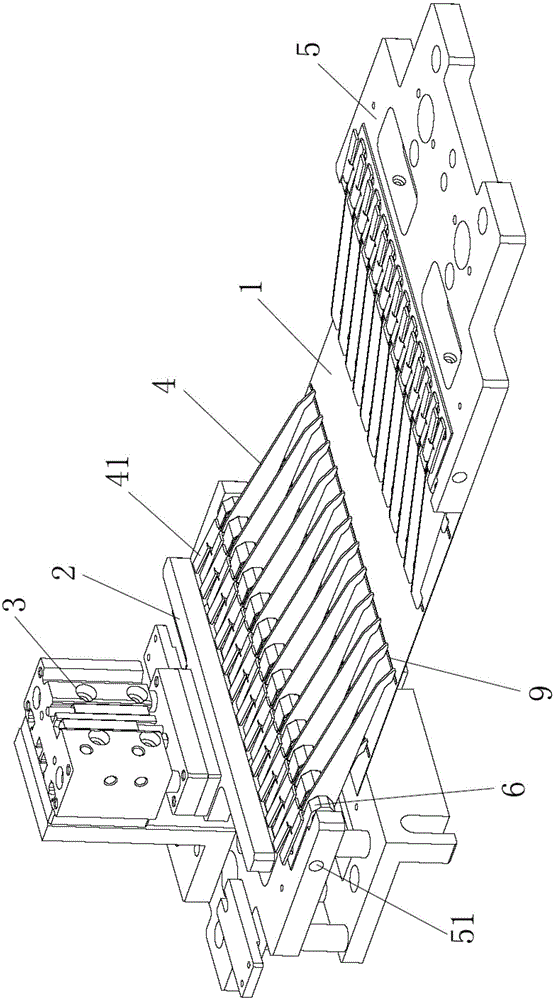

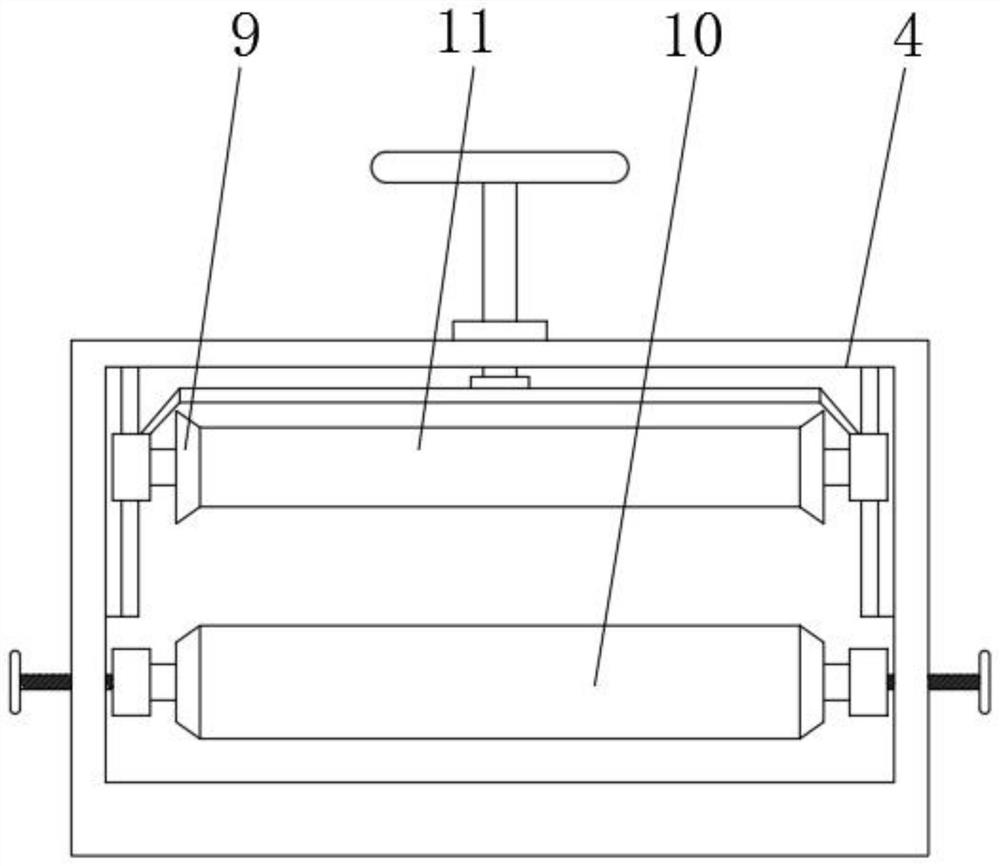

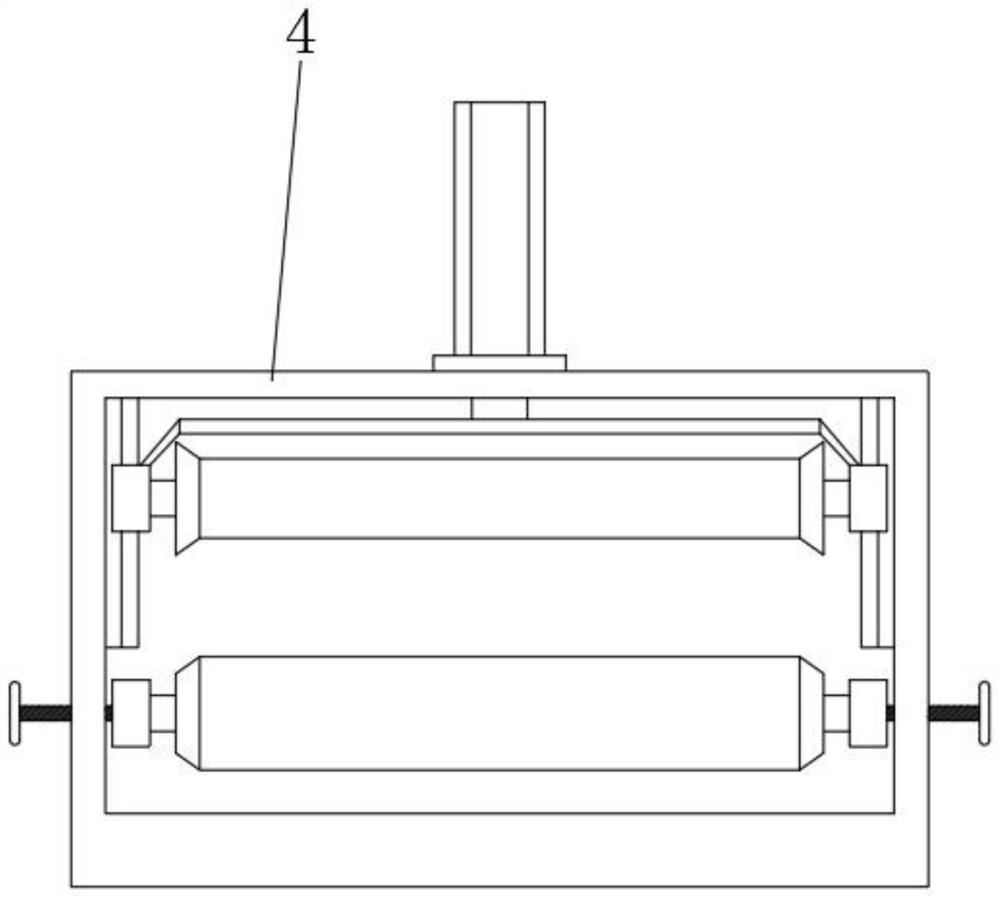

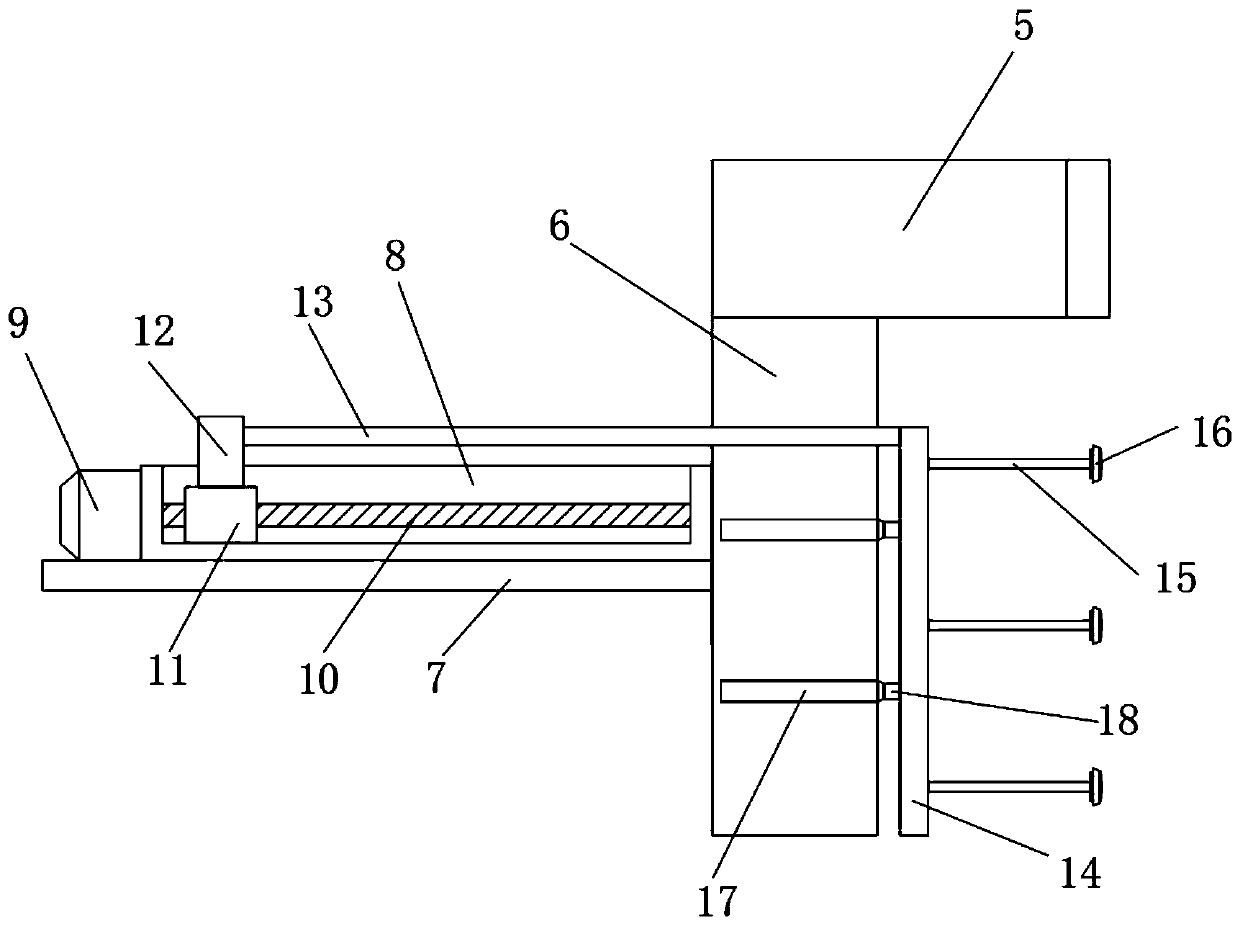

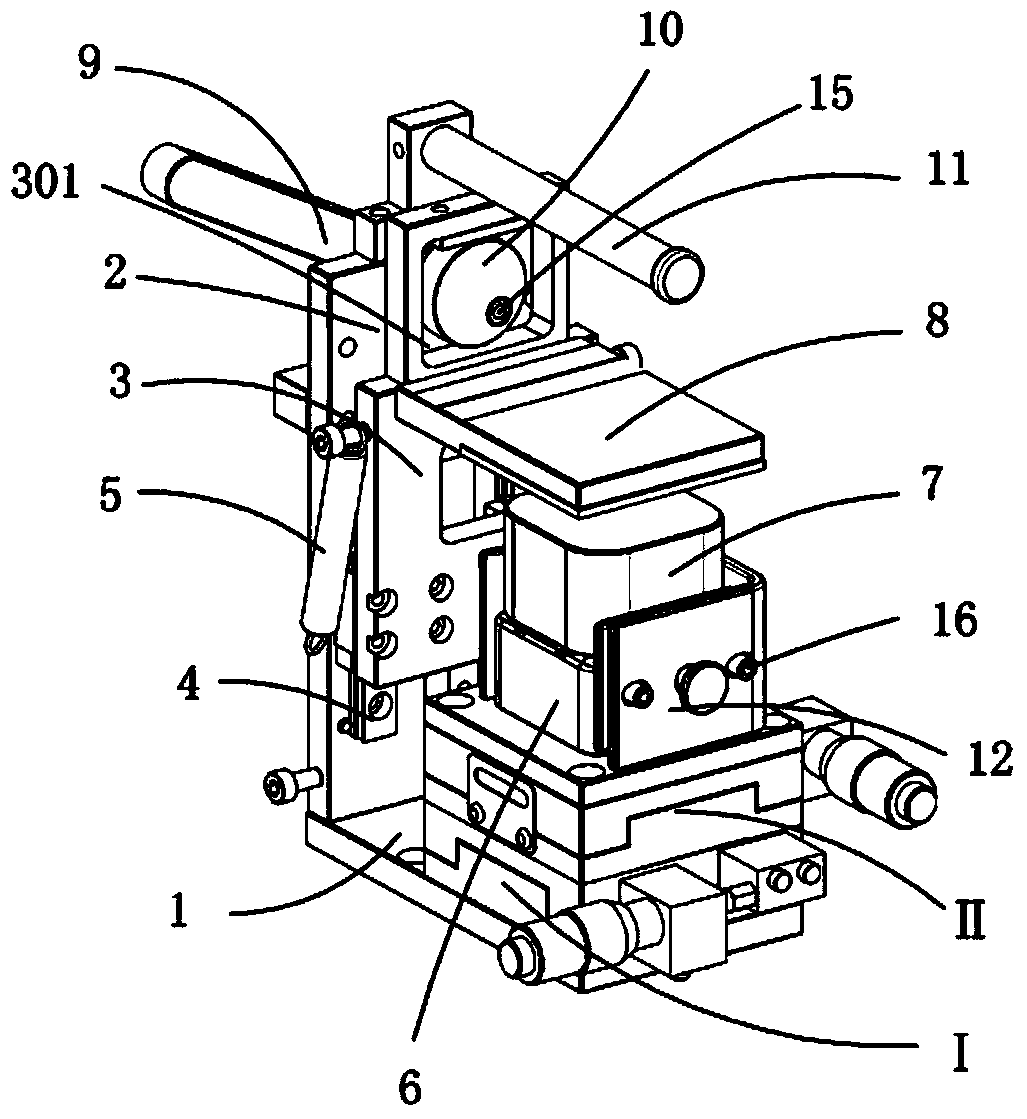

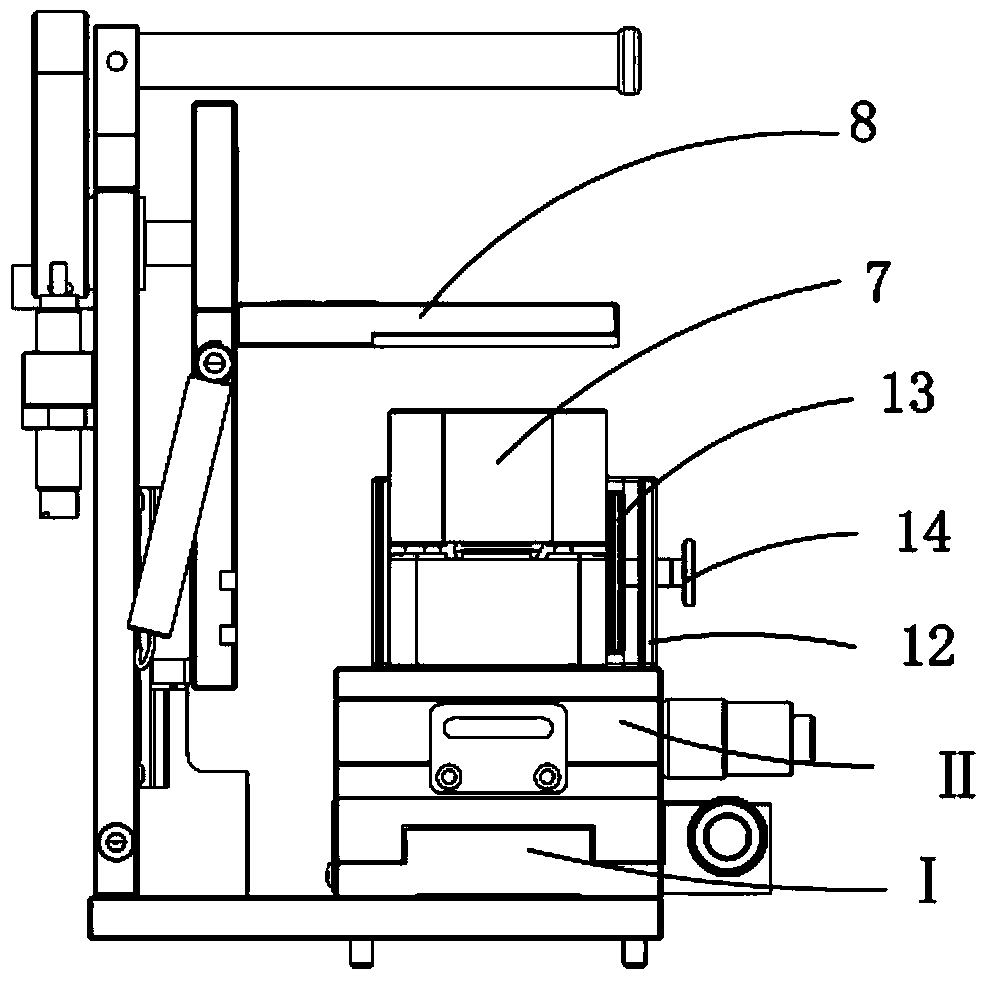

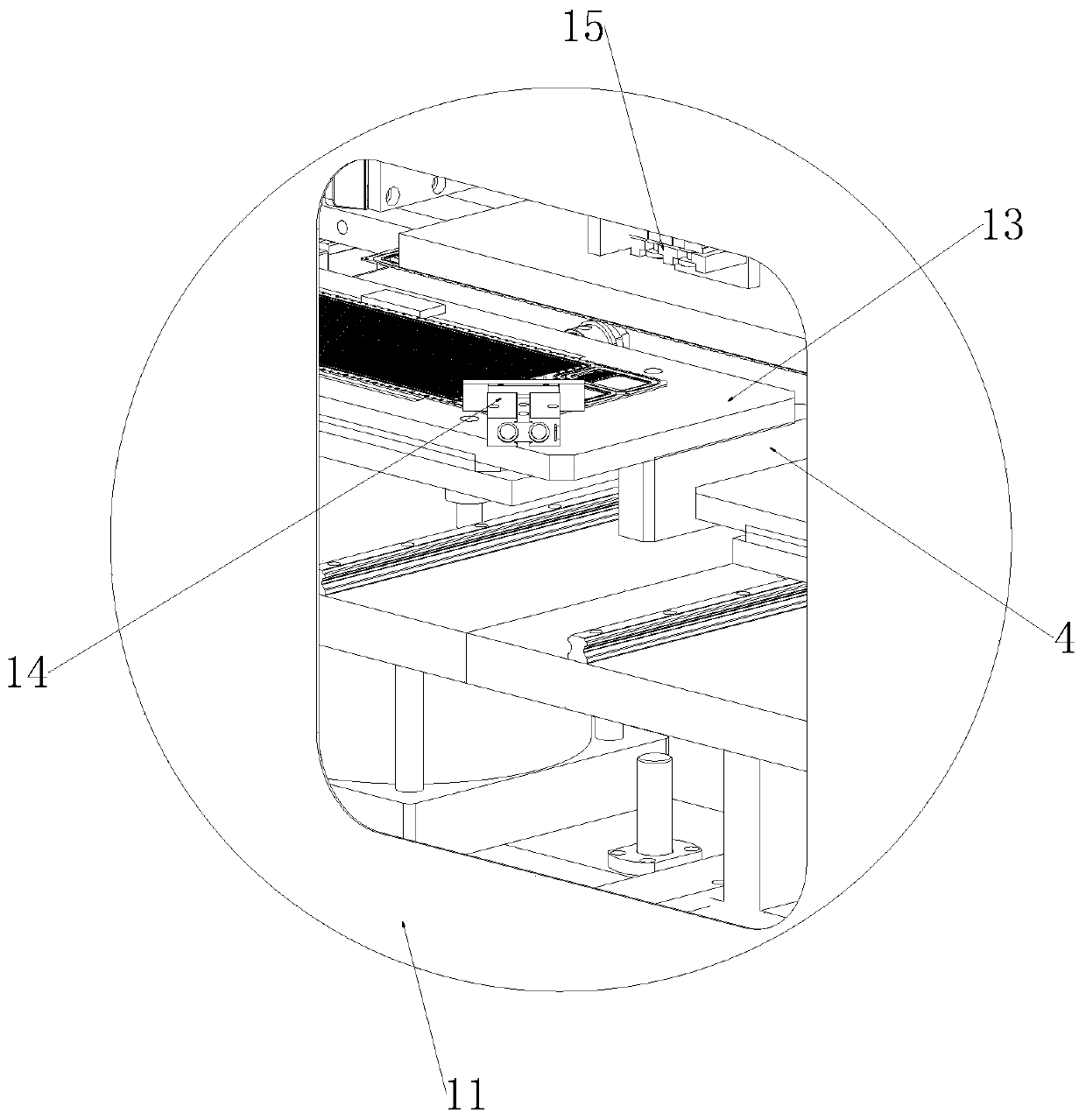

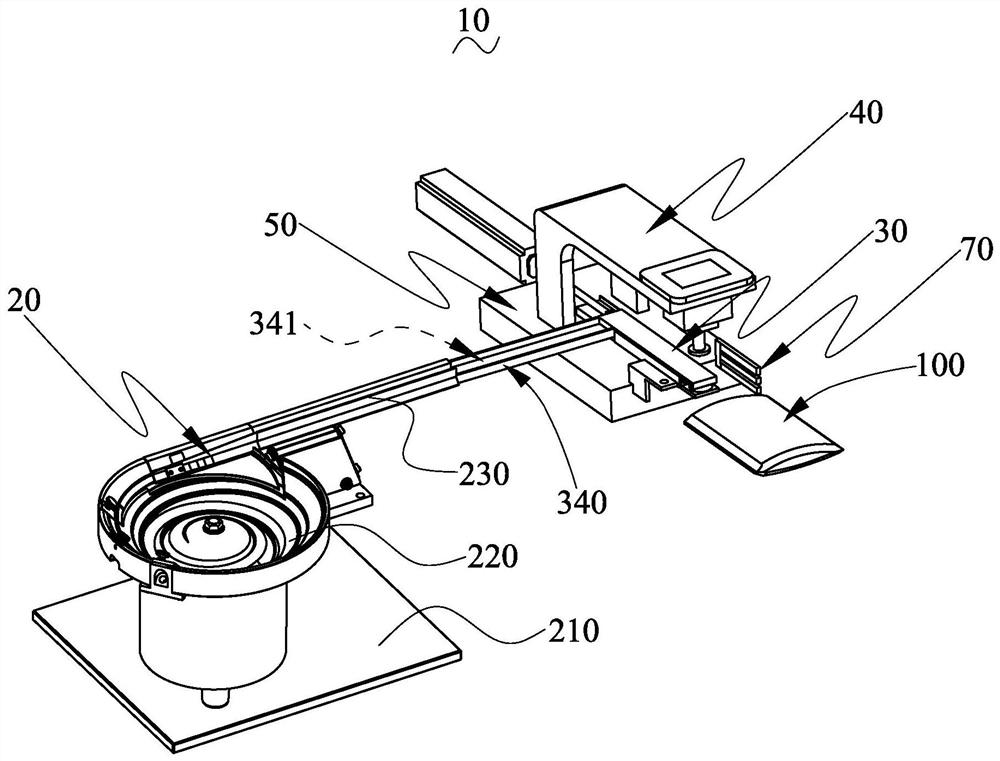

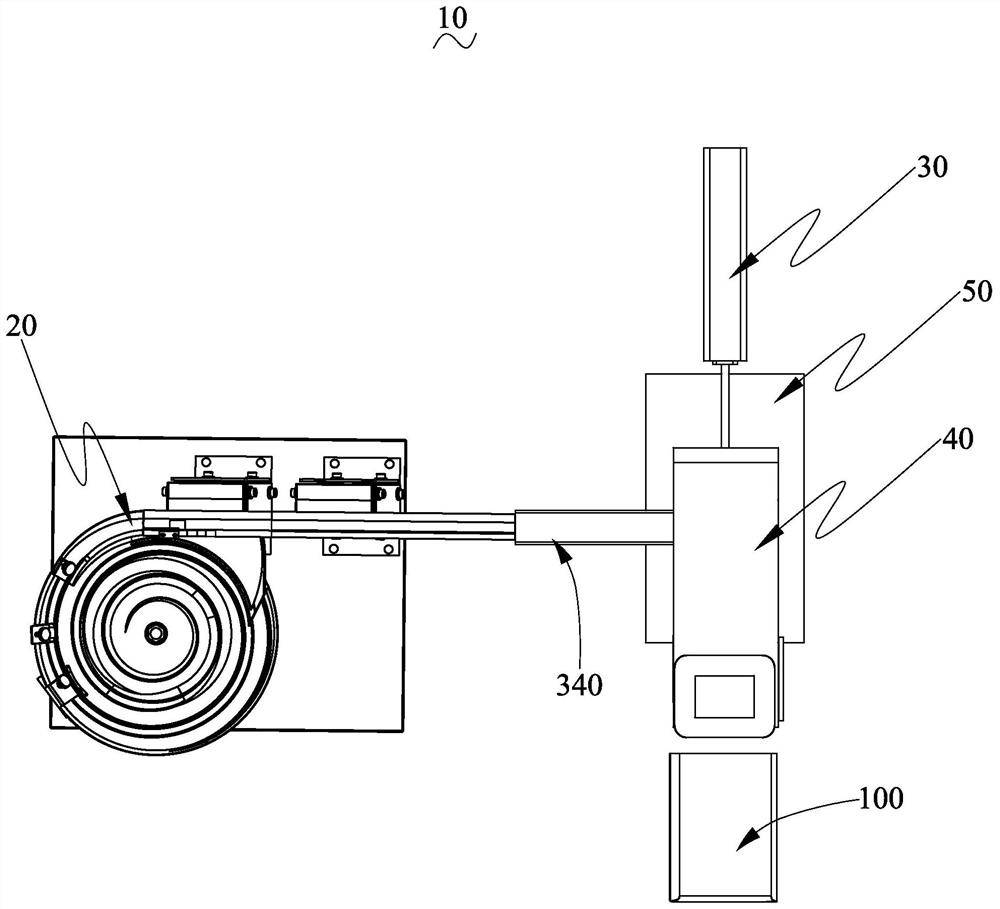

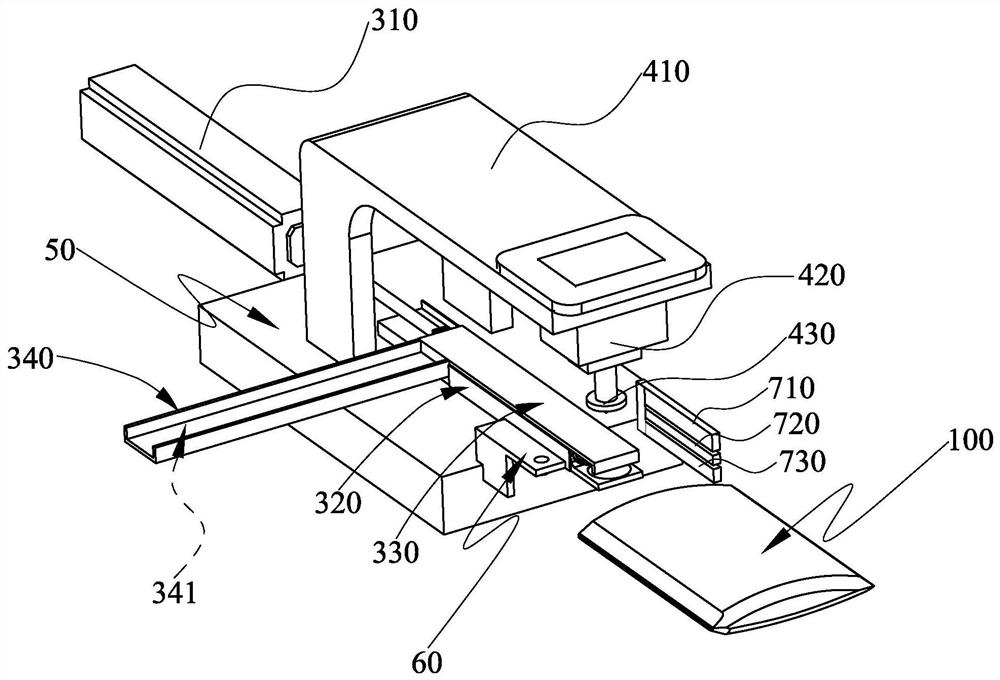

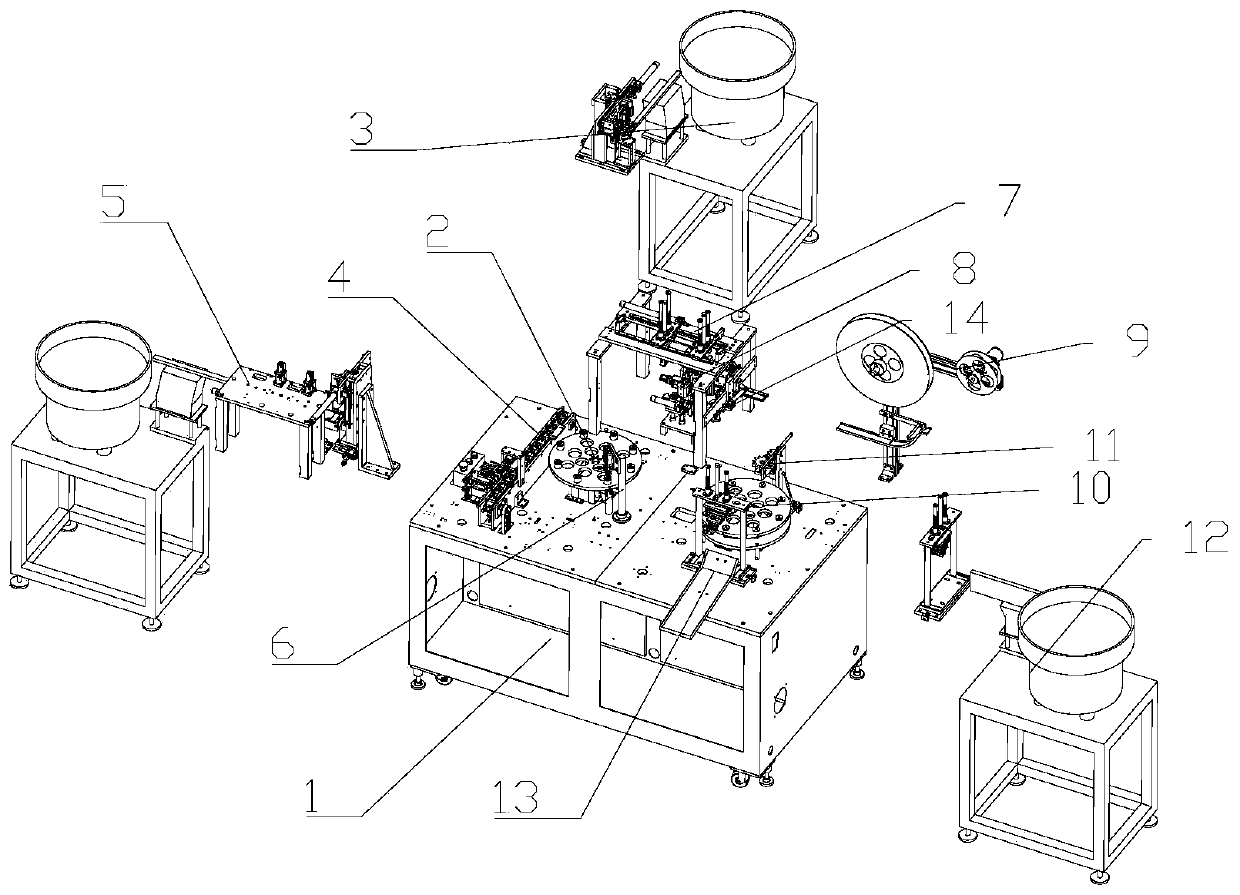

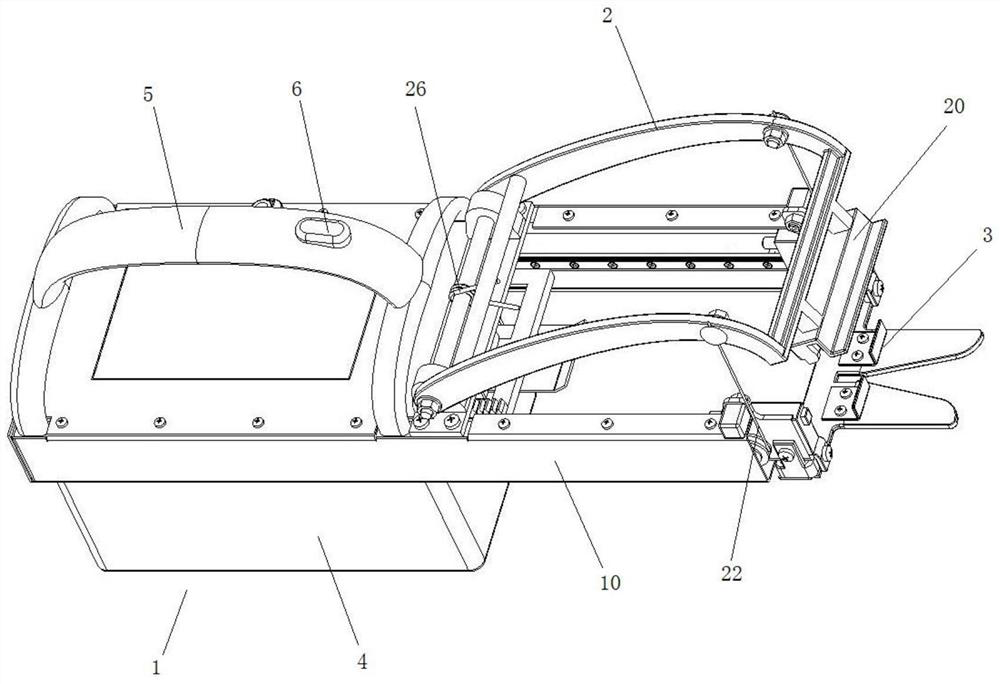

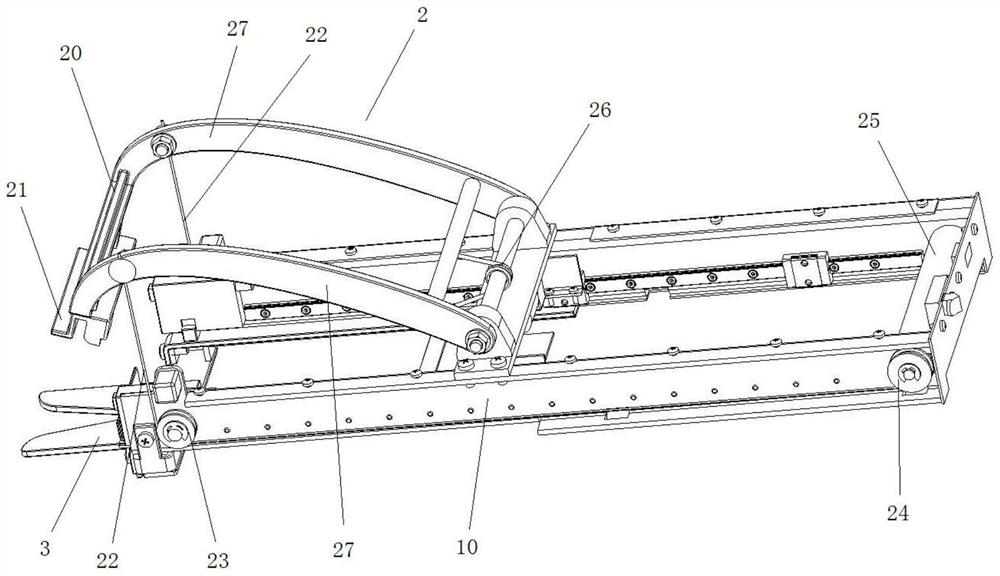

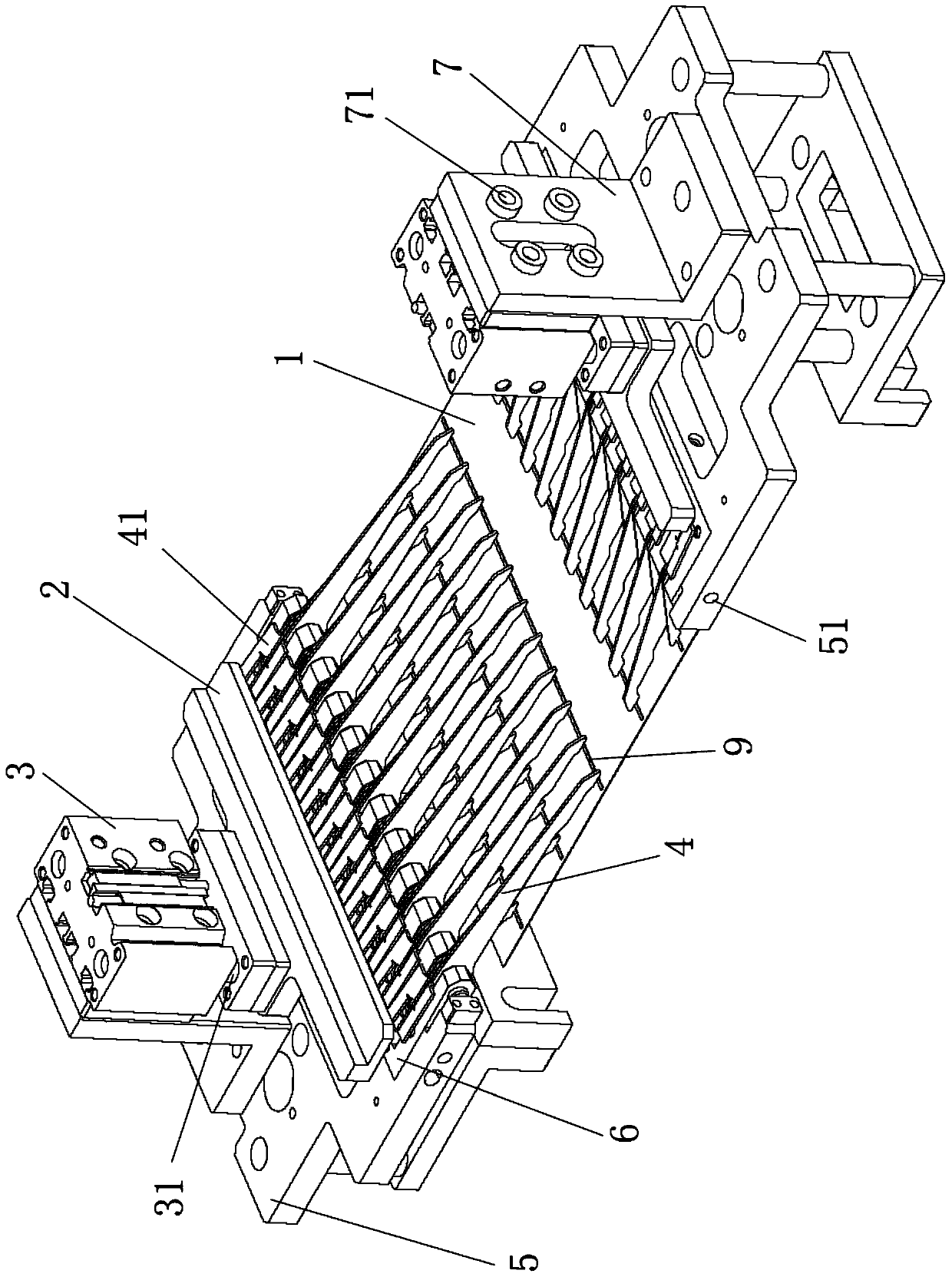

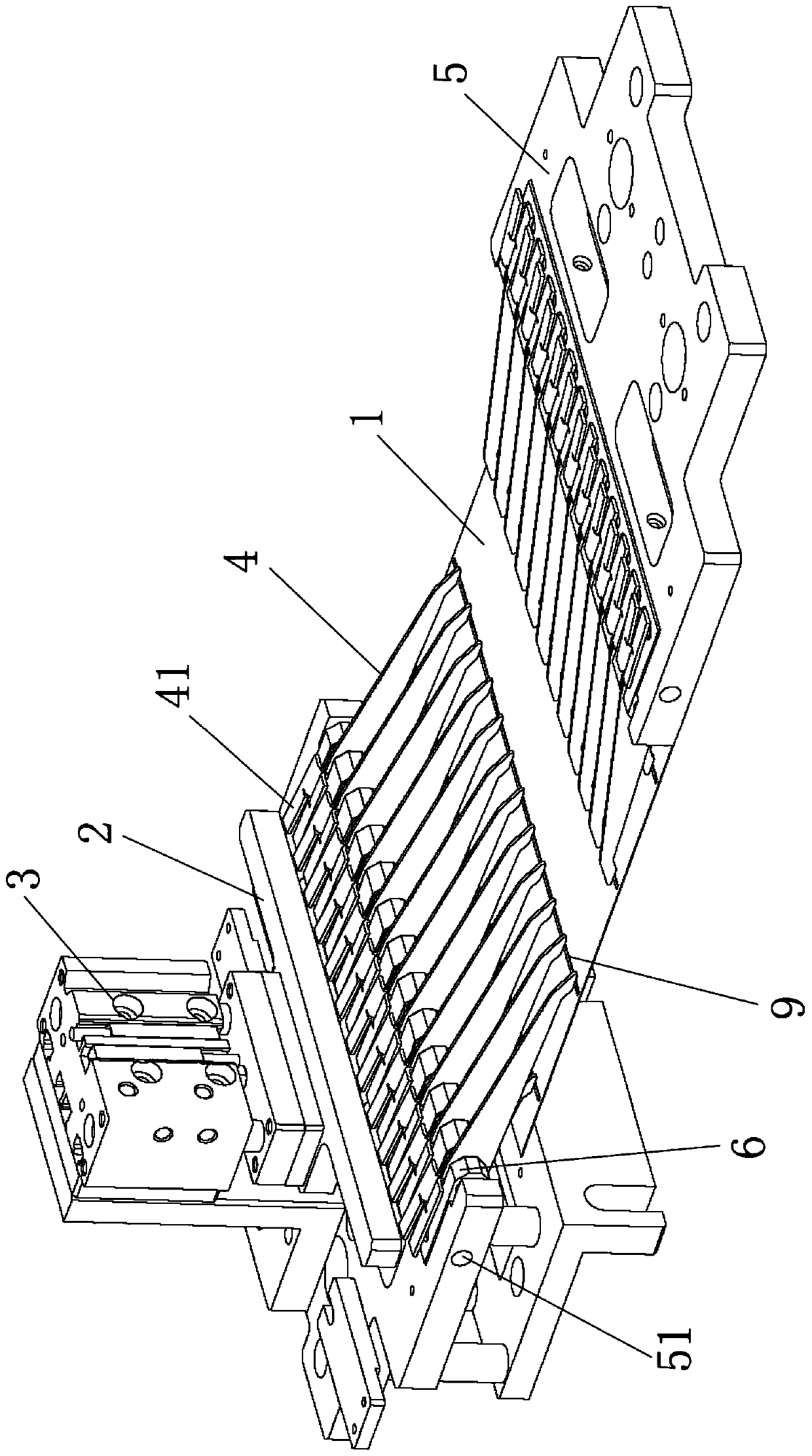

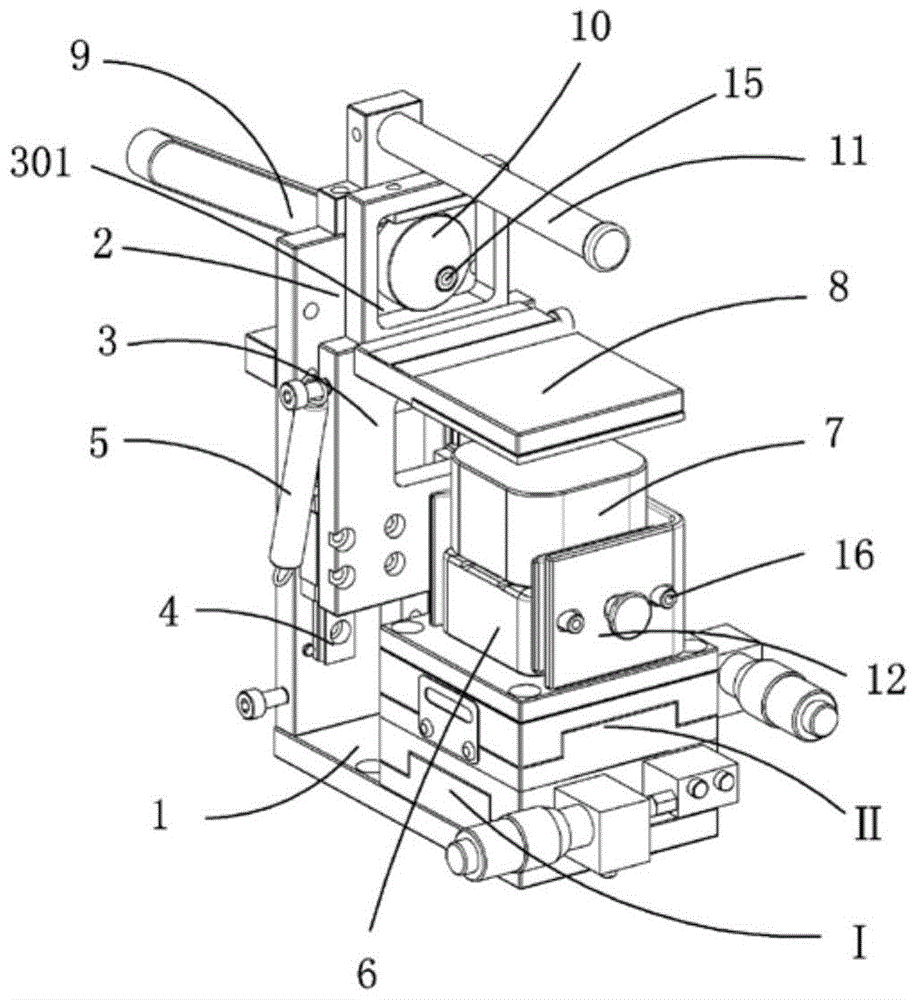

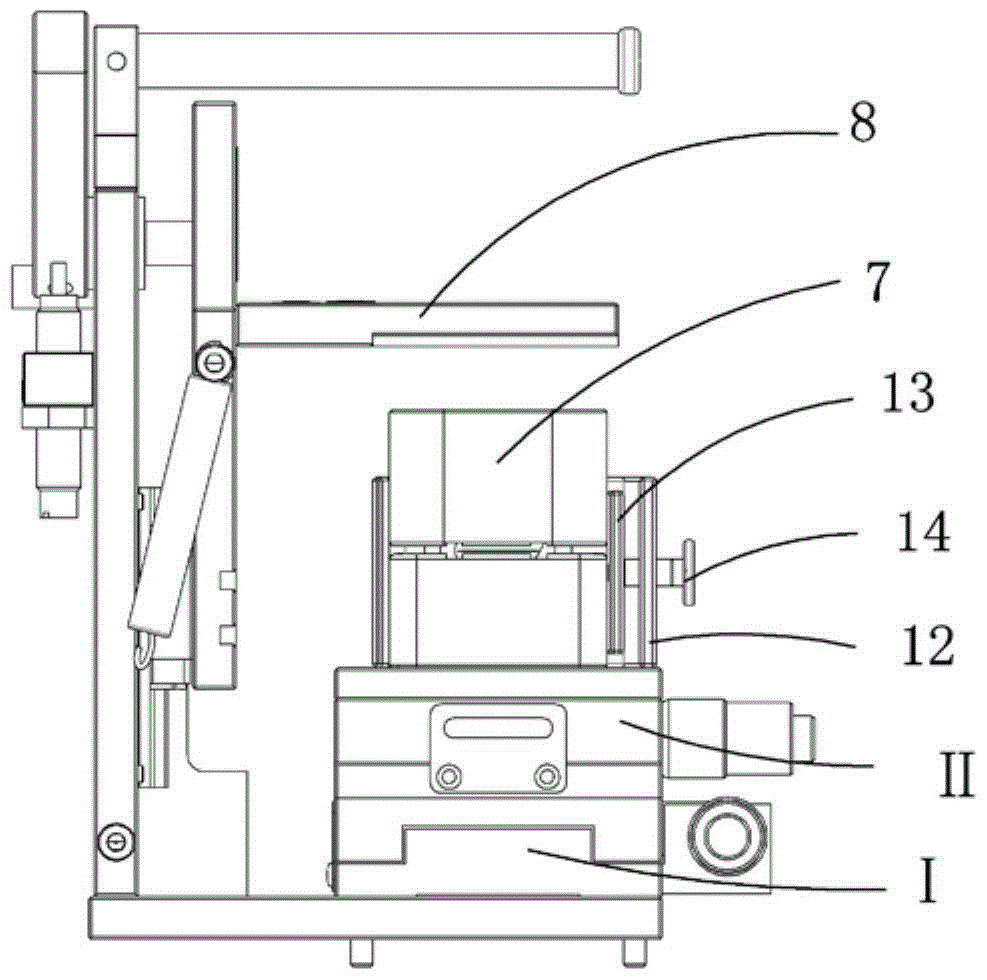

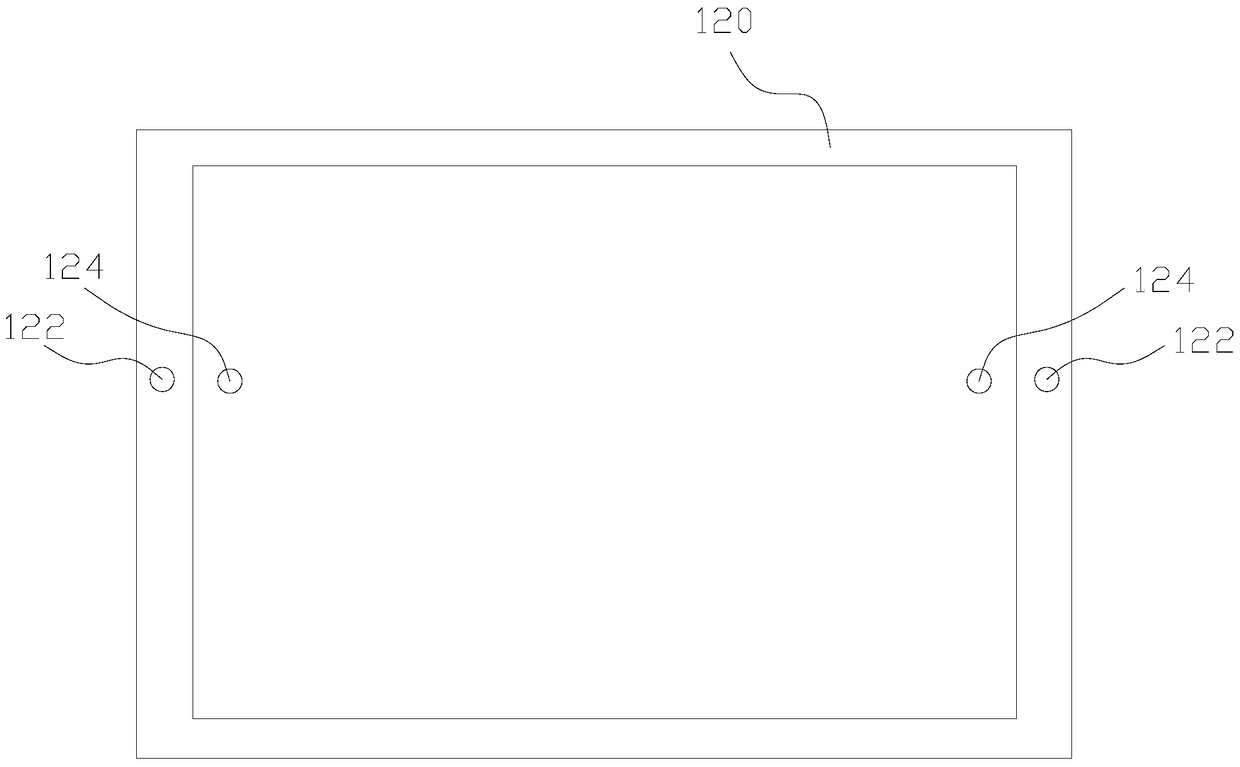

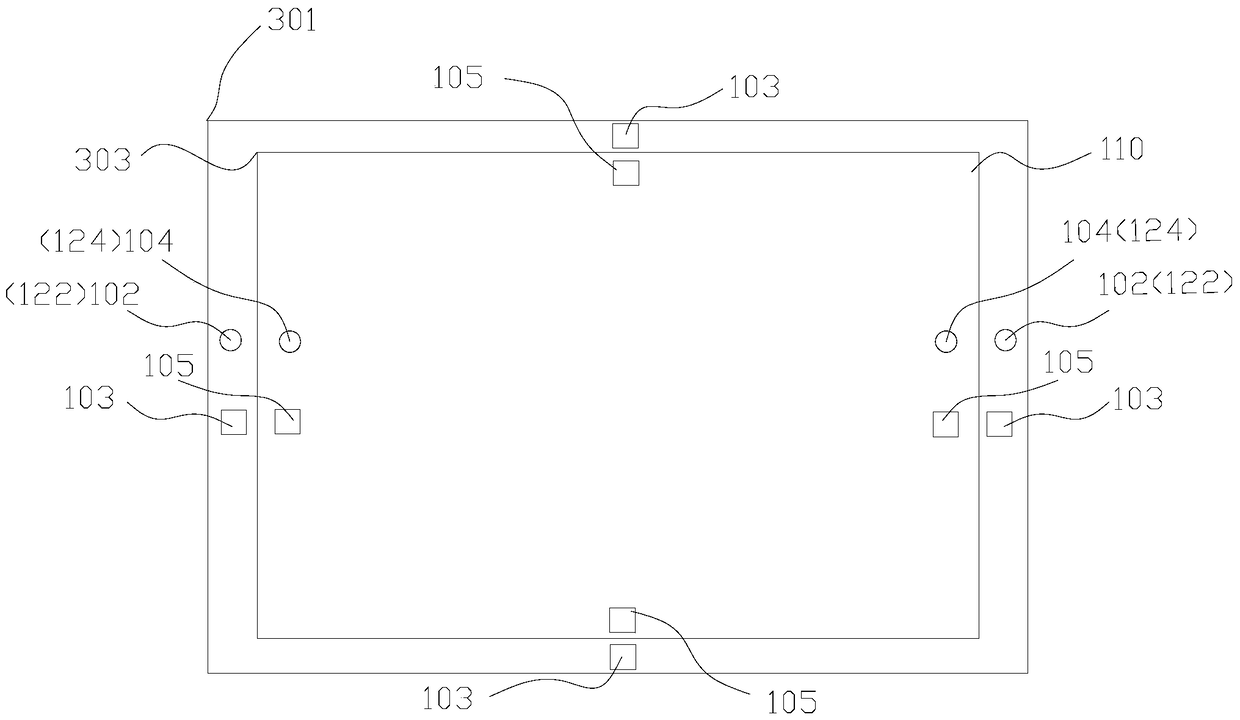

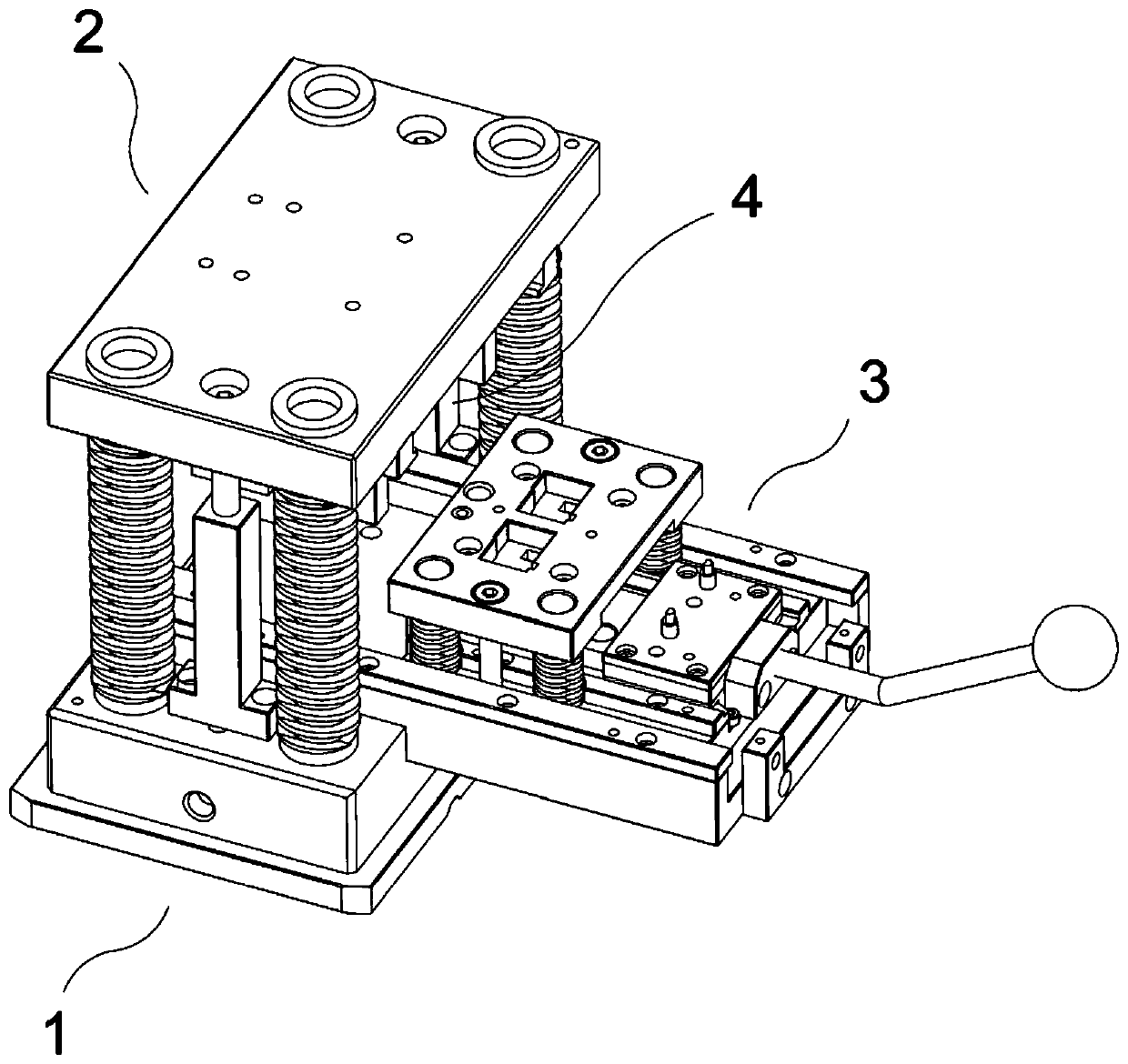

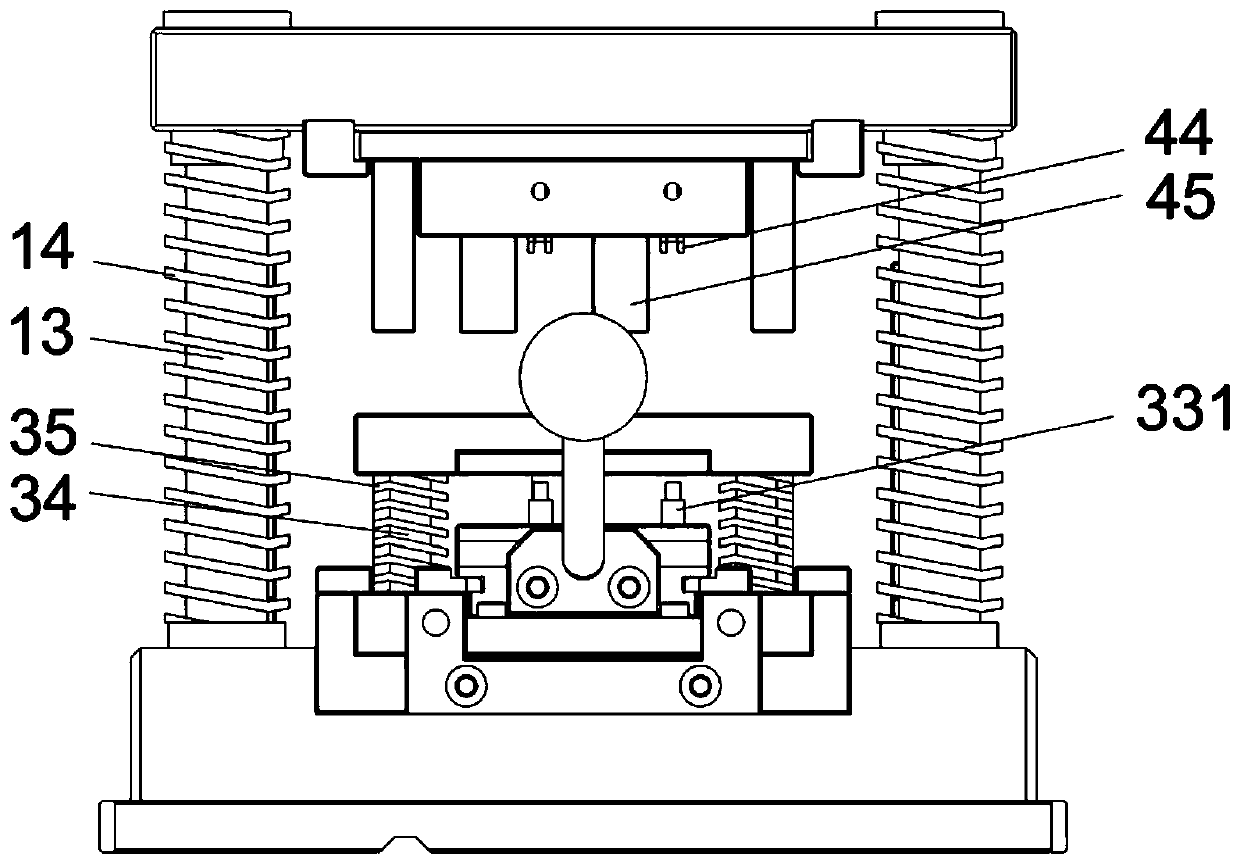

Automatic press-fitting mechanism for earphones

ActiveCN103634732AReduce labor intensityImprove pressing accuracyElectrical transducersEngineeringSlide plate

The invention relates to an automatic press-fitting mechanism for earphones. A rear vertical plate is disposed on a bottom plate and provided with a slide rail; a sliding plate is mounted on the slide rail; the upper portion of the sliding plate is provided with a square slot; a position handle is mounted behind a rear vertical plate through a rotating shaft; an eccentric wheel is mounted on the rotating shaft and disposed in the square slot; a pressure plate is mounted on the sliding plate; a left-right adjustment component is mounted on the bottom plate and provided with a front-back adjustment component; a lower press block is mounted on the front-back adjustment component; an upper press block is arranged above the lower press block, and an earphone is arranged between the upper press block and the lower press block; a knob is adjusted to adjust the front-back position of an elastic press block so as to align the upper press block and the lower press block; after alignment, an alignment regulator is removed; the front-back and left-right positions of the upper and lower press blocks are adjusted, the position handle is then manually operated to rotate the eccentric wheel, the sliding plate drives the pressure plate to move down, a spring on the side acts for buffering, the pressure plate presses down against the upper press plate, and the upper press block and the lower press block co-act to press-fit front and rear covers of the earphone.

Owner:BOZHON PRECISION IND TECH CO LTD

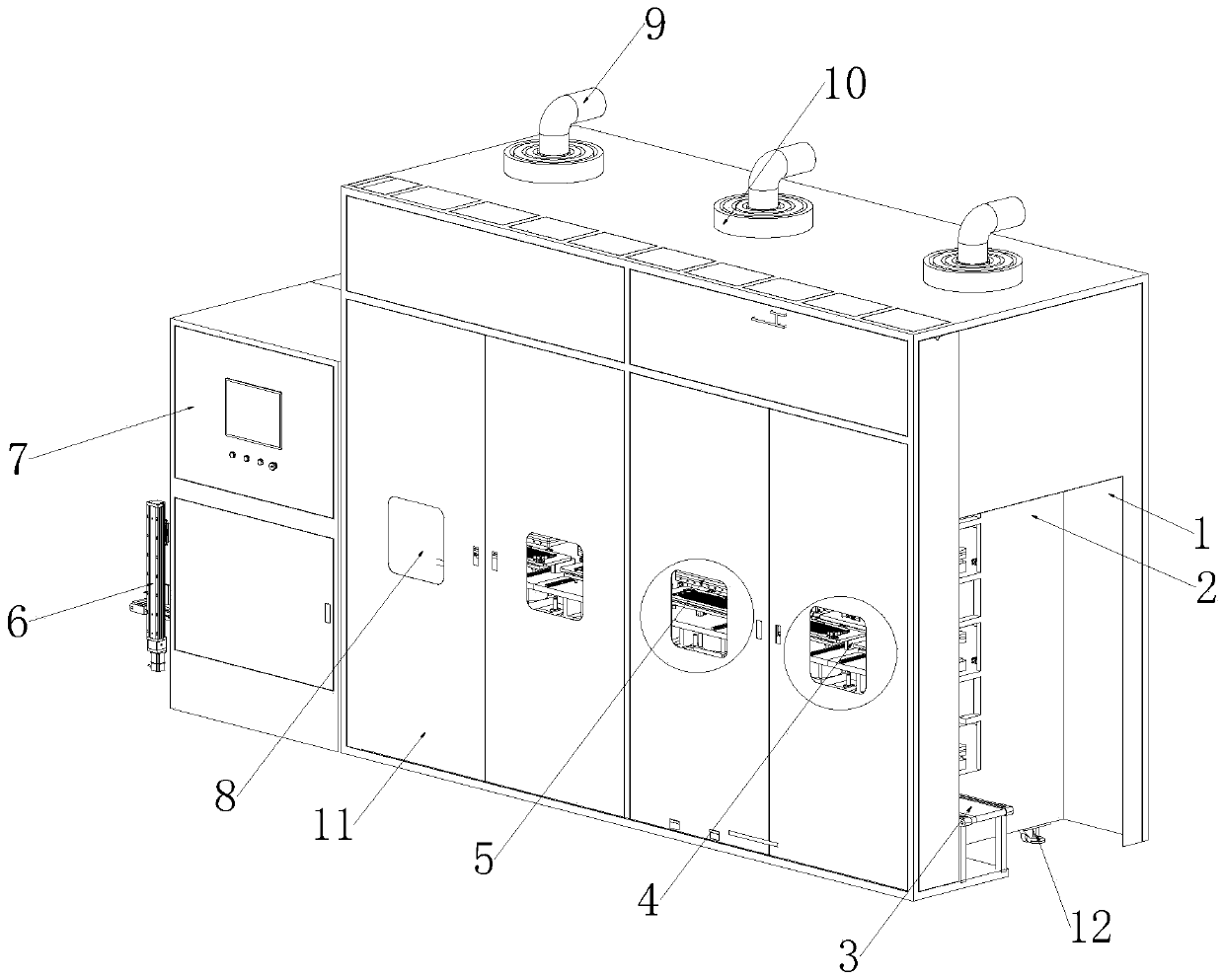

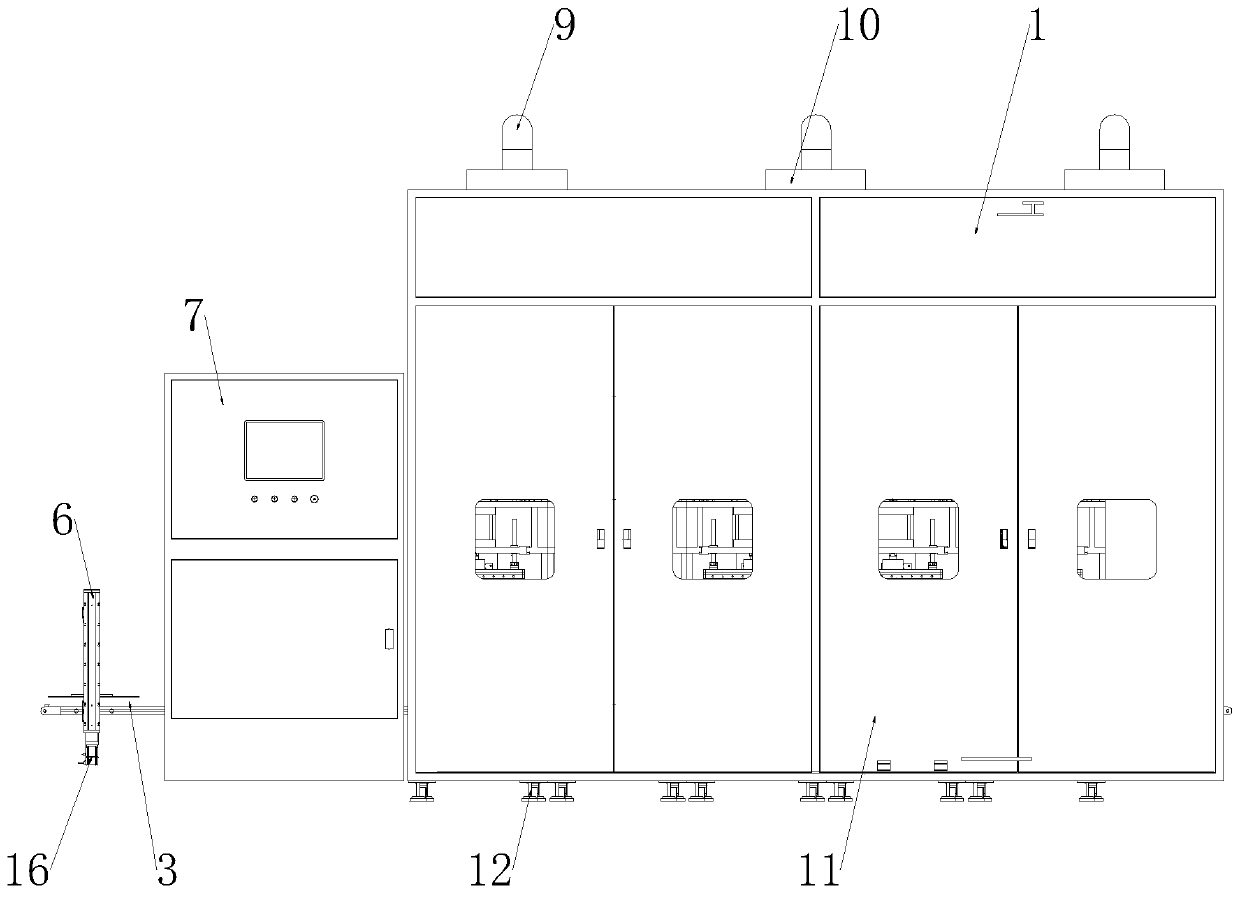

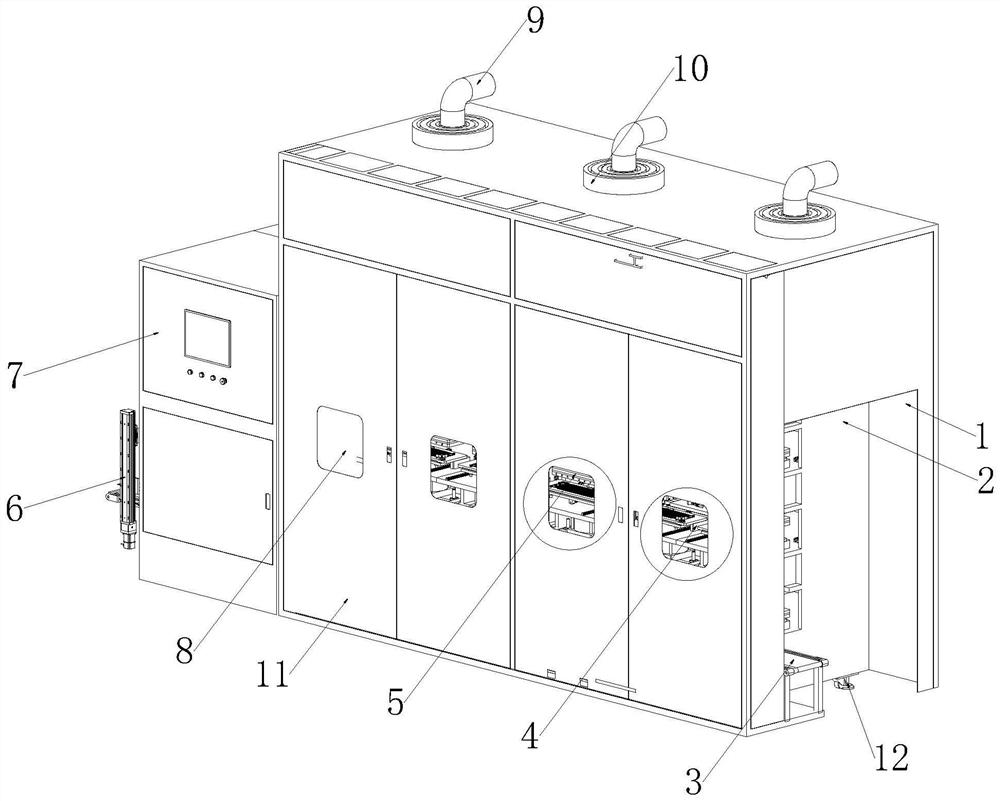

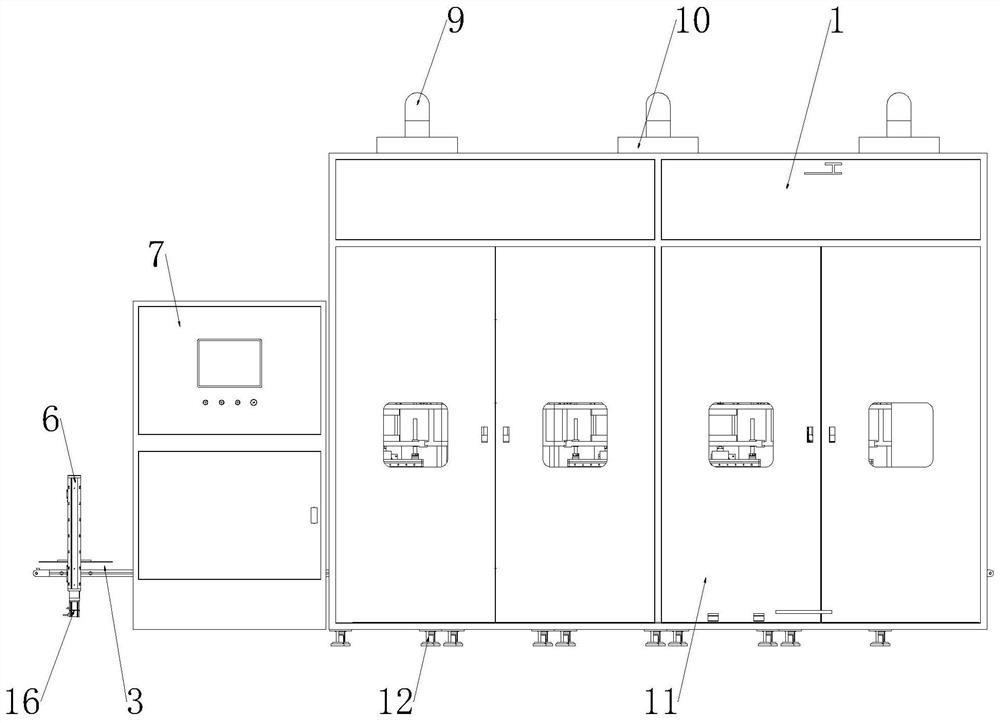

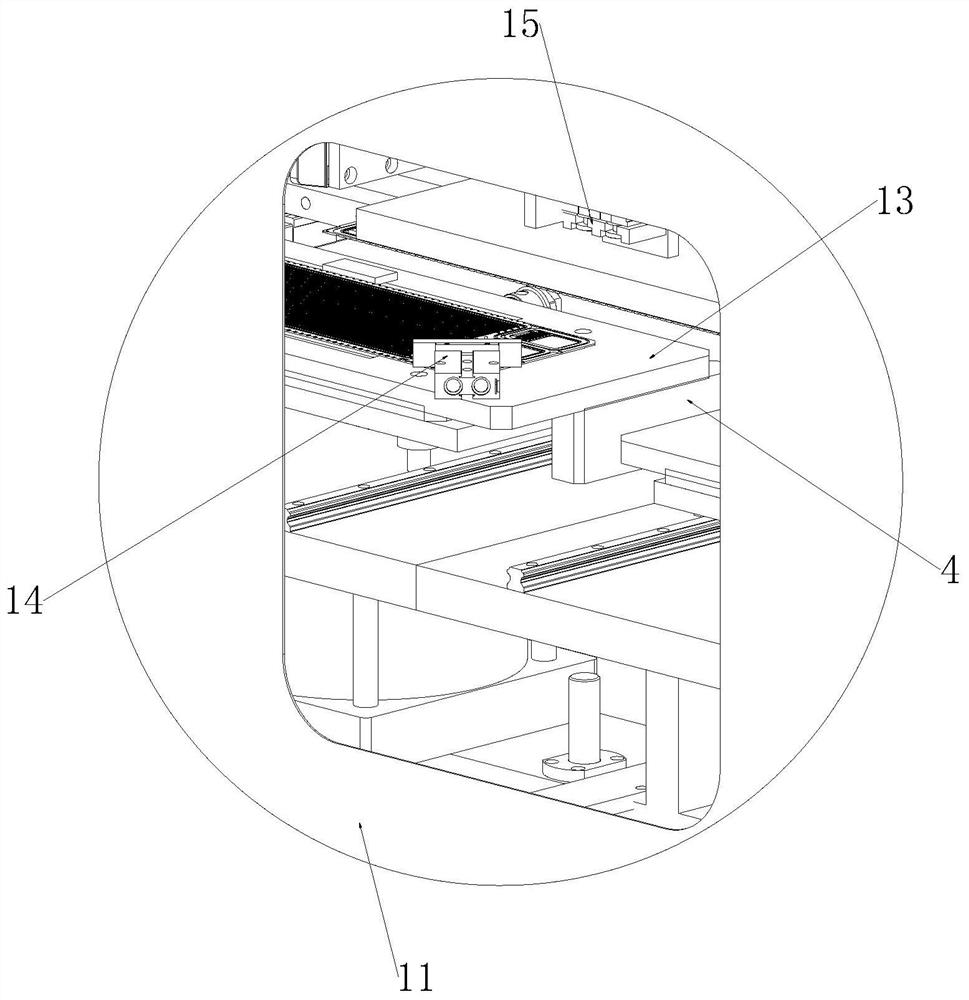

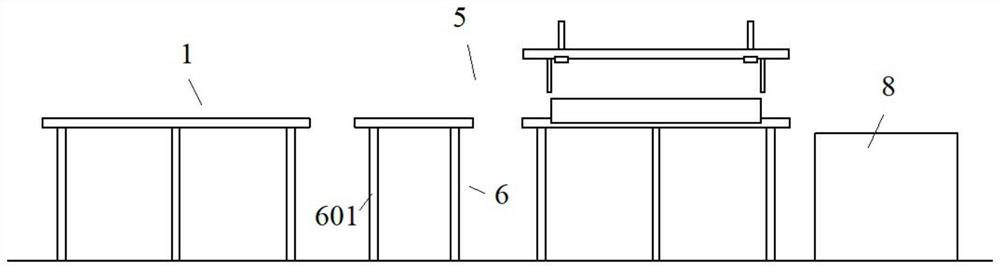

Hydrogen fuel cell bipolar plate thermocuring pressure maintaining equipment

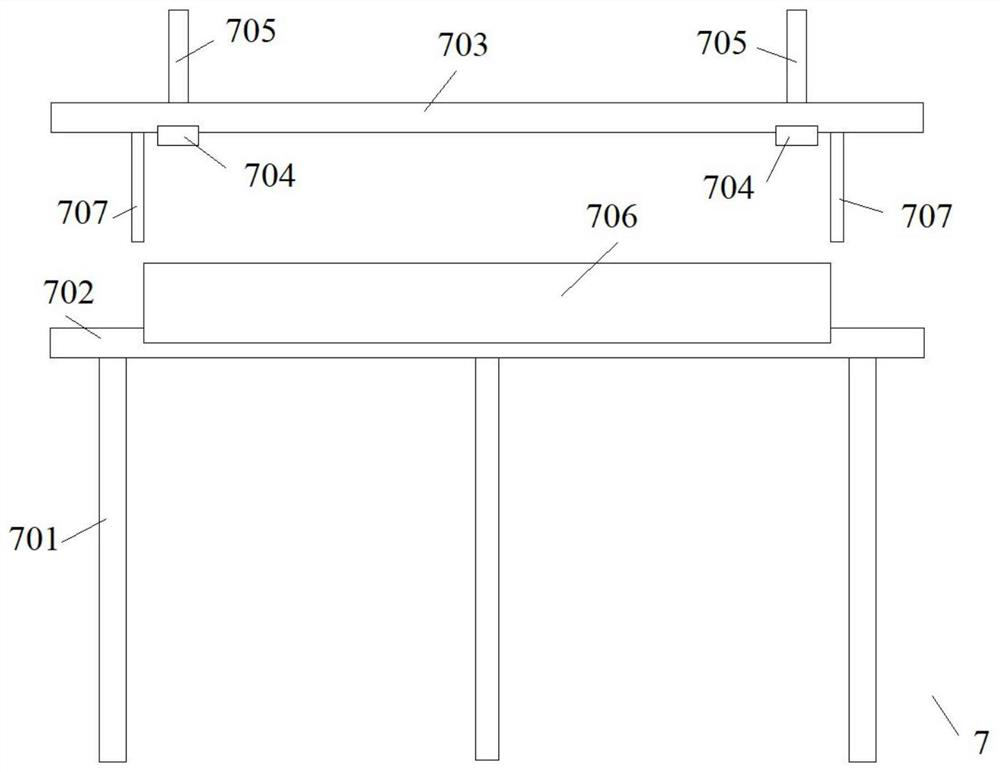

ActiveCN110341225AShorten the lengthPrevent wet misalignmentFouling preventionFinal product manufactureLocking mechanismHydrogen fuel cell

The invention discloses hydrogen fuel cell bipolar plate thermocuring pressure maintaining equipment comprising an equipment body. A dustproof outer cover is installed at the top of the equipment body. A floor mat is installed at the bottom of the equipment body. A conveying line is installed on one side of the equipment body. A lifting mechanism is installed on one side of the conveying line. A base is installed at the bottom of the lifting mechanism. A lower heating jig is installed on the side face of the equipment body. An upper heating jig is installed at the top of the lower heating jig.A servo press is installed at the top of the upper heating jig. A locking mechanism is installed at the top of the lower heating jig. A door plank is installed on the side face of the dustproof outercover. A glass view window is embedded in the side face of the door plank. The hydrogen fuel cell bipolar plate thermocuring pressure maintaining equipment is provided with the upper heating jig, thelifting mechanism, the lower heating jig and the servo press, and thus the problems that common pressure maintaining equipment is only provided with a single pressure maintaining station, the space utilization rate is low, loss of electric power resources is large during work, production cost is high, and production efficiency is low are solved.

Owner:深圳市昆龙卓盈机电有限公司

Laminate composite board producing press facilitating adjustment of thickness of board material

The invention discloses a laminate composite board producing press facilitating adjustment of the thickness of a board material. The laminate composite board producing press facilitating the adjustment of the thickness of the board material comprises a base; a fixed mold plate is fixed to the outer wall of the top end of the base through a bolt; a lower cushion plate is fixed to the outer wall ofthe top end of the fixed mold plate through a bolt; a lower mold plate is connected to the outer wall of the top end of the lower cushion plate through a bolt; the outer wall of the top end of the fixed mold plate is provided with a hole; a second hydraulic oil cylinder is fixed to the inner wall of the hole through a bolt; a top plate is fixed to one end of a piston rod of the second hydraulic oil cylinder through a bolt, and is located on the inner wall of the bottom end of the lower mold plate; and the outer wall of the top end of the lower cushion plate is provided with two openings. According to the laminate composite board producing press facilitating the adjustment of the thickness of the board material, by adding positioning nails with the models capable of being fast replaced, thethickness of a composite board can be fast adjusted, a guiding column and a guiding groove matched with the guiding column can be fast and accurately pressed, and a bottom plate and the hydraulic oilcylinder can be subjected to demolding. According to the laminate composite board producing press facilitating the adjustment of the thickness of the board material, the pressing thickness of the composite board can be fast and conveniently adjusted, the pressing precision is high, and the production efficiency is improved.

Owner:天津金创装饰工程有限公司

Material roller press for making cement

InactiveCN108325616AExpand the pressing rangeAffect qualityGrain treatmentsEngineeringMechanical engineering

The invention provides a material roller press for making cement, wherein the material roller press includes a material groove; a press roller is arranged on the material groove, a lifting cylinder isarranged above the press roller, connecting arms are arranged at both ends of the press roller, and the press roller and the lifting cylinder are connected together through the connecting arms; material finishing plates are arranged at both sides of the material groove respectively, and the rear part of each material finishing plate is provided with a material finishing cylinder; the material finishing plates are pushed to push dispersed materials to under the press roller by the material finishing cylinders; the lifting cylinder is provided with a reciprocating motor, and the lifting cylinder is driven to move back and forth by the reciprocating motor. The press roller is driven to extrude and crush the materials by the lifting cylinder, the materials moving at two sides are pushed backto under the press roller by the material finishing plates, and thus the pressing precision is increased; moreover, the press roller is driven to move back and forth by the reciprocating motor, so thepressing range of the press roller is increased, and the pressing efficiency is increased; meanwhile, with arrangement of a cleaning disk, the press roller is cleaned, so the materials are preventedfrom attaching on the press roller, the materials of two times of work are prevented from being mixed, and the quality of the materials is prevented from being affected.

Owner:JIANGSU XINYE HEAVY IND

A kind of hydrogen fuel cell bipolar plate thermal curing pressure maintaining equipment

ActiveCN110341225BShorten the lengthPrevent wet misalignmentFouling preventionFinal product manufactureHydrogen fuel cellEngineering

The invention discloses a hydrogen fuel cell bipolar plate thermal curing and pressure maintaining equipment, comprising an equipment body, a dust-proof cover is installed on the top of the equipment body, a foot pad is installed at the bottom of the equipment body, and a side of the equipment body is installed with a dust-proof cover. Conveying line, a lifting mechanism is installed on one side of the conveying line, a base is installed at the bottom of the lifting mechanism, a lower heating tool is installed on the side of the equipment body, and an upper heating tool is installed on the top of the lower heating tool, and the upper heating tool is installed A servo press is installed on the top of the lower heating tool, a locking mechanism is installed on the top of the lower heating tool, a door panel is installed on the side of the dustproof cover, and a glass window is embedded in the side of the door panel. The invention solves the general pressure maintaining equipment by setting the upper heating tool, the lifting mechanism, the lower heating tool and the servo press, only a single pressure maintaining station is set, the space utilization rate is low, the loss of power resources during operation is large, and the production cost is high. high and low productivity.

Owner:深圳市昆龙卓盈机电有限公司

Cold storage plate production system

The invention relates to a cold storage plate production system which comprises a cutting device, a laminating device and a foaming glue injection device which are sequentially arranged, the cutting device comprises a rack, a rough cutting module and a fine cutting module, and the rough cutting module and the fine cutting module are sequentially arranged on the rack; the rough cutting module comprises a first conveying roller, paired grinding rollers, a cutting roller and a second conveying roller which are sequentially arranged on the rack in parallel and are perpendicular to the axis direction of the rack, a first cutter is movably arranged on the cutting roller, and the fine cutting module comprises a plurality of cutters, a third conveying roller and a pressing plate which are arranged on the two sides of the rack in pairs; the cutter is arranged between the second conveying roller and the third conveying roller, the third conveying roller is parallel to the second conveying roller, and a second cutter and a plurality of pressing rods are movably arranged on the pressing plate. Compared with the prior art, the device is high in cutting precision, good in cutting efficiency, high in laminating precision and good in foaming glue injection effect.

Owner:SHANGHAI BESTSTEEL STEEL STRUCTURE BUILDING

Pressing device on aluminum substrate production line

ActiveCN113133231ACompact structureReasonable designMultilayer circuit manufactureProduction lineStructural engineering

The invention aims at providing a pressing device on an aluminum substrate production line. The pressing device comprises a machine base, a hot pressing assembly and a cold pressing assembly, the hot pressing assembly and the cold pressing assembly are assembled on the machine base, an annular rail is assembled on the machine base, the hot pressing assembly and the cold pressing assembly are located on the outer side of the annular rail, and at least two sliding seats are installed on the annular rail in a sliding mode. A machine frame further comprises a driving mechanism used for driving the sliding seats to slide on the annular rail, a vertically-through step groove is formed in the outer side portion, away from the annular rail, of each sliding seat, a separating seat is erected on the step groove, jacking cylinders are arranged at the positions, located at the hot pressing station and the cold pressing station, of the machine base respectively, a lifting plate is fixedly installed at the top end of a movable rod of the jacking cylinder, and a limiting mechanism is arranged between the lifting plate and the separating seat. The hot pressing assembly comprises a first rack, a first pressing cylinder and a hot pressing plate, the first rack is fixedly installed on the machine base, and the first pressing cylinder is fixedly installed on the top of the first rack.

Owner:ANHUI LINCHI ELECTRONICS CO LTD

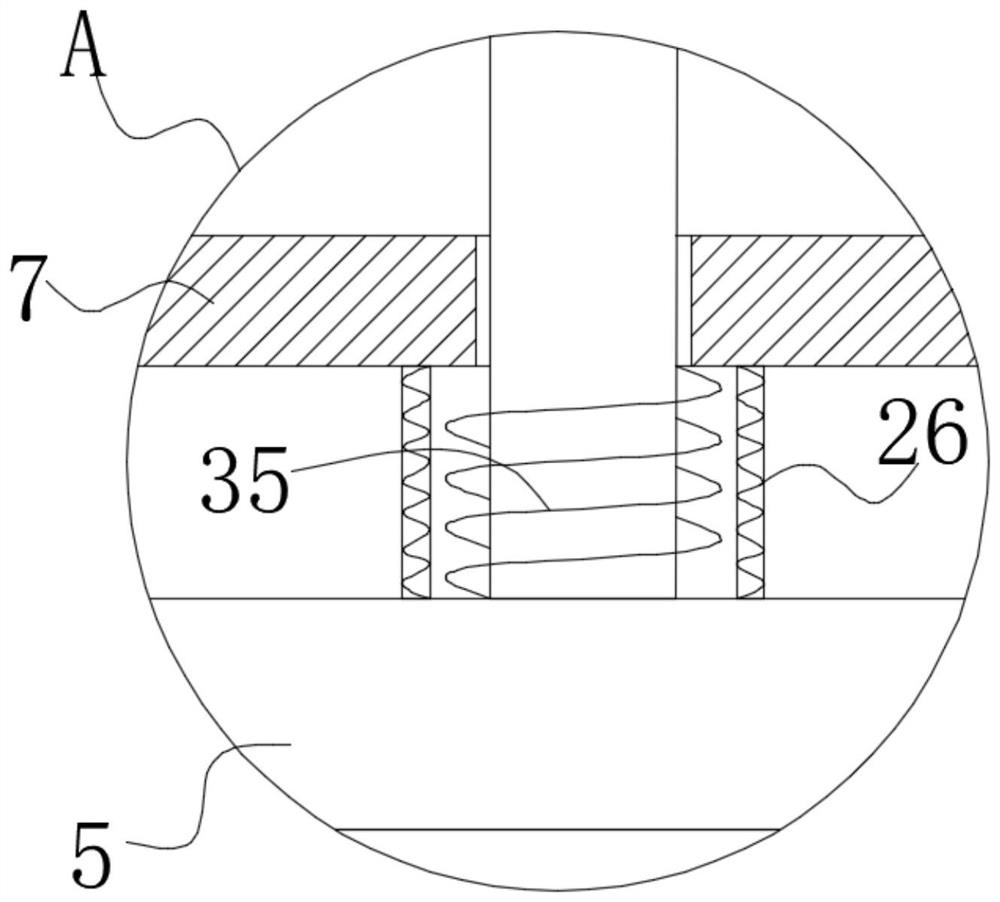

Air pressure valve equipment applied to packaging bag production

InactiveCN111960042AImprove pressing accuracyIncrease productivityBag making operationsPaper-makingEngineeringMechanical engineering

The invention relates to air pressure valve equipment applied to packaging bag production. The air pressure valve equipment comprises a vibration disc, a conveying positioning mechanism, a punching hot-pressing mechanism and a base, wherein the conveying positioning mechanism and the punching hot-pressing mechanism are arranged on the base, and the conveying positioning mechanism communicates withthe vibration disc; the conveying positioning mechanism comprises a conveying driver, a conveying guide member and a conveying member, the conveying guide member is arranged on the base and providedwith a conveying guide part and a positioning part, a height difference is formed between the conveying guide part and the positioning part, and the conveying guide part is provided with a conveying guide channel; and the conveying member is arranged in the conveying guide channel in a sliding mode, and the conveying driver is in driving connection with the conveying member so that the conveying member can get close to or get away from the positioning part of the conveying guide member along the conveying guide channel and the conveying guide channel can communicate with or separated from thevibration disc. The air pressure valve equipment applied to packaging bag production is high in production efficiency, the pressing precision of an air pressure valve is high, and the production yieldis high.

Owner:ASUWANT PLASTIC PACKAGING CO LTD

Circuit board laminating and pressing method

InactiveCN110324993AAvoid press fit offsetImprove pressing accuracyMultilayer circuit manufacturePunchingElectrical conductor

The invention relates to the technical field of circuit board processing, and discloses a circuit board laminating and pressing method; the circuit board laminating and pressing method comprises the following steps that a plurality of single-layer core boards which are stacked into a multi-layer board are prepared, wherein each core board comprises at least one layer of conductor layer; by takingthe center point of the single-layer core board as a base point, a plurality of sets of circuit arrangement are symmetrically designed on the single-layer core board, wherein at least four sets of circuit arrangement are arranged; punching is carried out on the single-layer core boards; tool holes are manufactured in a mode that a drilling mode is replaced by a process method of punching multipleholes in one time; and circuit processing is carried out on the single-layer core boards. According to the circuit board laminating and pressing method, by taking the center point of the single-layercore board as a base point, a plurality of sets of circuit arrangement are symmetrically designed on the single-layer core board, so that the resultant force on the multiple sets of circuits on the single-layer core boards in the subsequent pressing process is the same, the phenomenon that the circuit board is pressed in an offset mode due to non-uniform pressing stress of the circuit board is further avoided, and the effect of efficient pressing and offset prevention is achieved.

Owner:重庆科迈电子科技有限公司

A keyboard with an "I" shape keycap integrally formed by injection molding

ActiveCN106128830BImprove pressing accuracyPrevent excessive deformationEmergency actuatorsElectric switchesEngineeringInjection moulding

The invention relates to an injection-molded one-piece keyboard with an I-shaped keycap, a mold and a production method. The keyboard comprises the one-piece I-shaped keycap, a printed circuit film and a keyboard base plate which supports the printed circuit film. Through slotting guidance of a hard sheet, a soft plastic convex flexible switch body is integrally injection-molded at the center inside the hard sheet. The soft plastic convex flexible switch body is directly molded at the center of the hard sheet. When pressing is carried out, the soft plastic convex flexible switch body is directly pressed by the hard sheet, so that the pressing accuracy is high. The technical problems of injection molding and mold stripping of a traditional structure are solved. The entire keyboard has the advantages of small key surface gap and smooth key surface. An adhesive structure is used, so that the keyboard has the advantages of less product parts, thin overall thickness, light weight, simple assembly and low cost. A positioning ring is arranged at the bottom surface of the hard sheet to improve the pressing feel and balance.

Owner:江海波

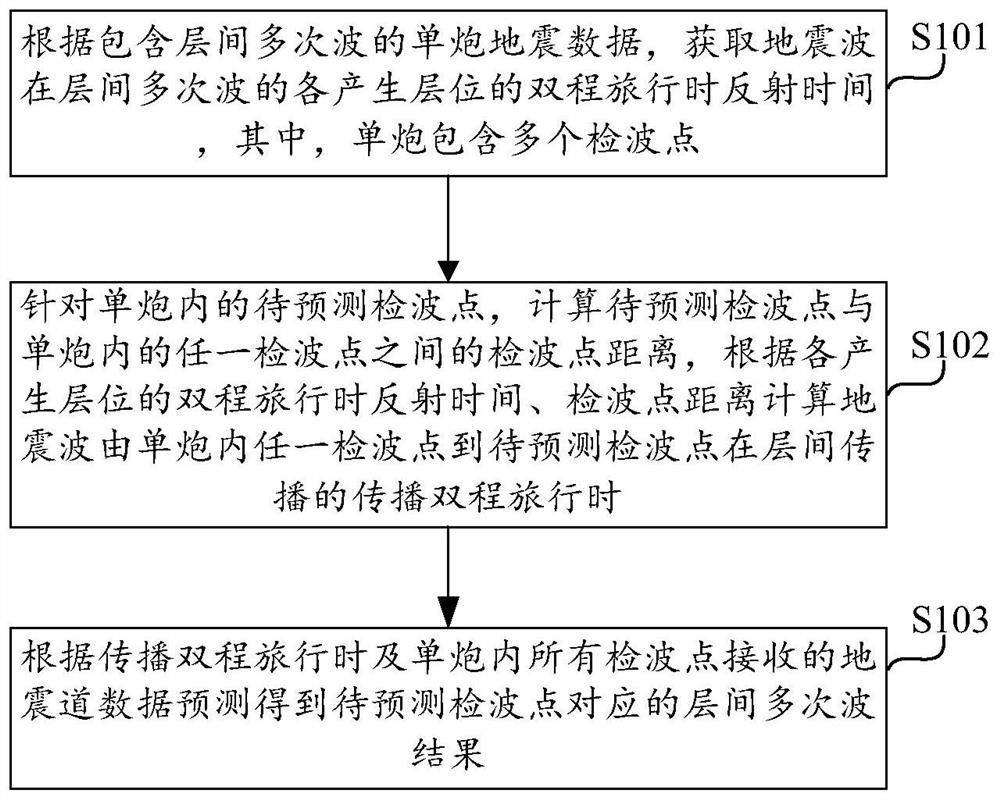

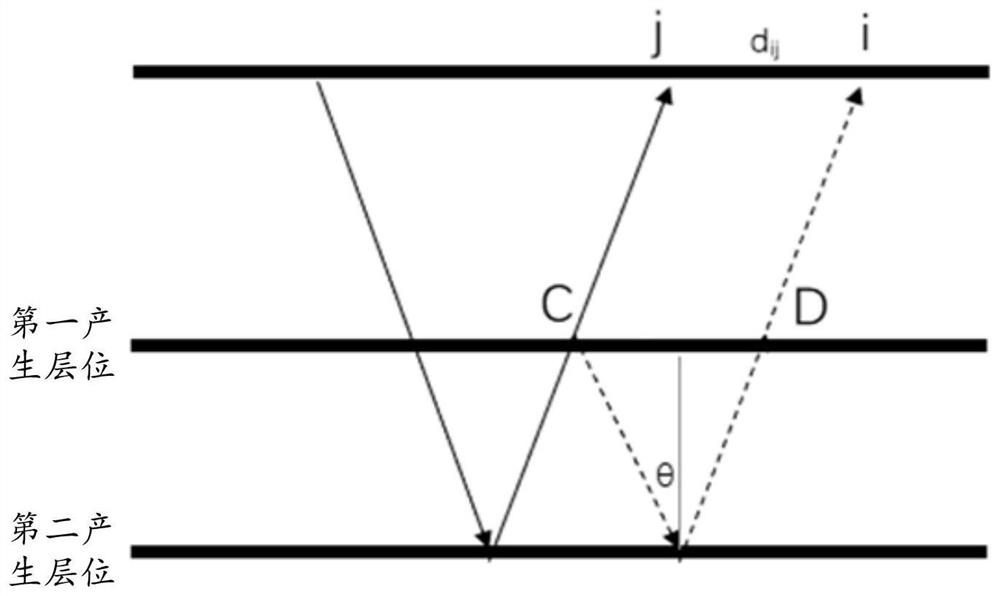

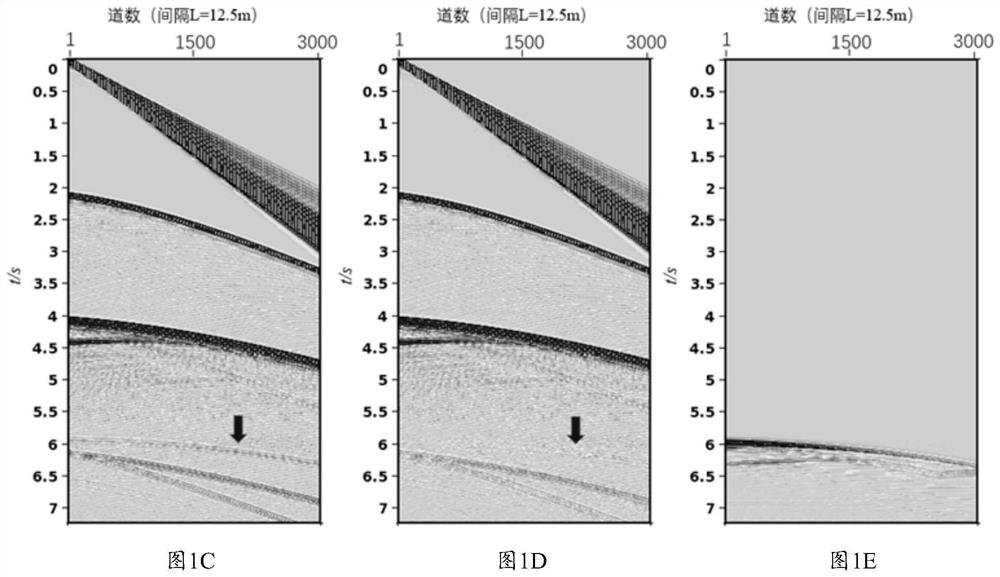

Interlayer multiple prediction method and device

PendingCN114779327AImprove accuracyHigh precisionSeismic signal processingComputational physicsSingle shot

The invention discloses an interlayer multiple prediction method and device. The method comprises the following steps: according to single-shot seismic data containing interlayer multiples, obtaining two-way travel time reflection time of seismic waves at each generation horizon of the interlayer multiples; for a to-be-predicted detection point in the single shot, calculating the detection point distance between the to-be-predicted detection point and any detection point in the single shot, and calculating the propagation double-pass travel time of the seismic wave propagating between the layers from any detection point in the single shot to the to-be-predicted detection point according to the double-pass travel time reflection time and the detection point distance of each generation layer; and predicting an interlayer multiple result corresponding to the to-be-predicted detection point according to the propagation two-way travel time and the seismic trace data received by all the detection points in the single shot. Therefore, the interlayer multiples formed between the strong reflection layers can be accurately predicted, the interlayer multiples can be accurately suppressed based on the result of the interlayer multiples, the suppression accuracy is improved, and the accuracy and precision of the correlation analysis result based on the suppressed seismic data are higher.

Owner:CHINA OILFIELD SERVICES

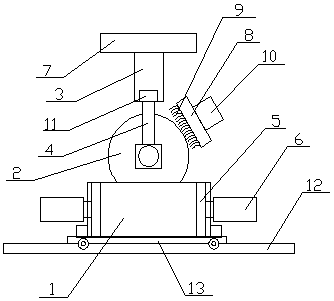

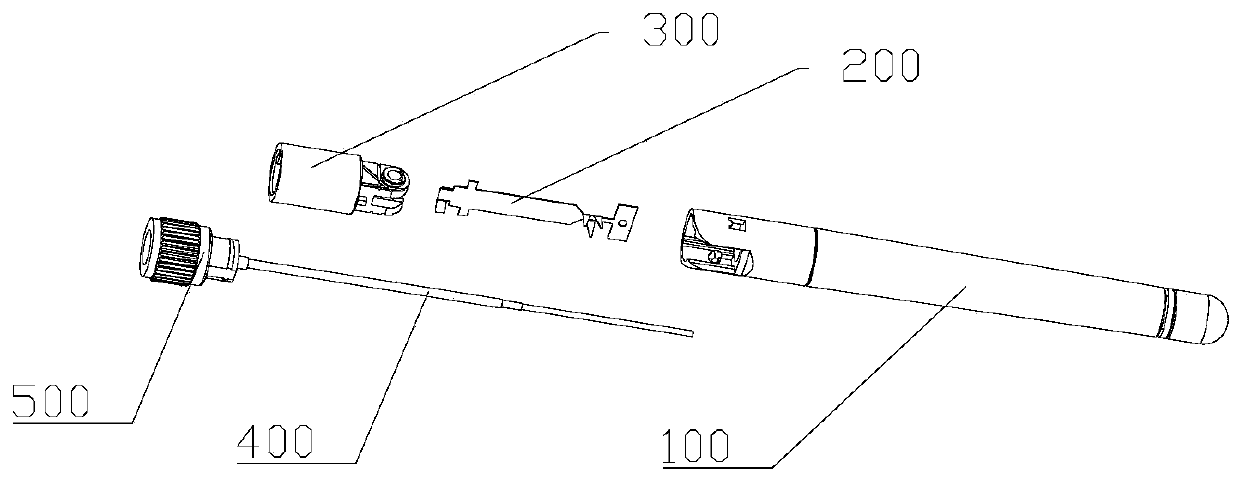

Protection rod assembly device for folding antennas

InactiveCN109759834APrevent movementImprove pressing accuracyAssembly machinesEngineeringMechanical engineering

The invention relates to the manufacturing field of communication equipment, in particular to automatic assembly equipment for folding antennas. A protection rod assembly device for the folding antennas comprises a material falling positioning mechanism and a pressing mechanism. The material falling positioning mechanism is arranged below the pressing mechanism, and the material falling positioning mechanism comprises a twelfth air cylinder, a seventh finger air cylinder and material falling guide blocks. The telescopic end of the twelfth air cylinder is connected with the seventh finger air cylinder, and the two material falling guide blocks are mounted at the moving end of the seventh finger air cylinder to combine into a cone, and a cylindrical hole for passing through an antenna core is formed in the middle of the cone. The pressing mechanism comprises a thirteenth air cylinder, a swinging plate, a fourteenth air cylinder and a rotating seat. The thirteenth cylinder is vertically mounted on the end part of the swinging plate, and the other end of the swinging plate is rotatably connected with a mandrel of the fourteenth air cylinder. According to the technical scheme, the protection rod assembly device for the folding antennas is adopted, the pressing mechanism can swing, a core body can be placed in a same station when the core body is put in and pressed, more efficiency is achieved, the core body is prevented from moving in the position of a protection rod, and the pressing accuracy is improved.

Owner:王朝火

An automatic young fruit bagging machine

ActiveCN105918025BAvoid harmAvoid accidental breakagePlant protective coveringsDrive wheelAgricultural engineering

The invention discloses an automatic young fruit bagging machine, which comprises an upper pressing frame and a fork plate device, the upper pressing frame includes a pressing fork, one end of the pressing fork is hinged on the frame, and the other end of the pressing fork is equipped with a pressing plate , the pressing plate is set above the fork plate device; the bottom of the frame is equipped with a bag storage box, the bag storage box is equipped with an automatic bag feeding device, and the upper end of the bag storage box is equipped with an automatic bag feeding device; the top of the frame is equipped with a handle , There is a control switch on the handle; two fork plates opened in a V shape are set on the fork plate device; one end of the pressing fork is fixedly connected with a pull rope, and the pull rope is connected to the driving wheel at the rear end of the frame after bypassing the driven wheel , the drive wheel is driven by the motor, and the control switch controls the motor to rotate forward or reverse. The automatic young fruit bagging machine of the present invention can realize automatic pressing and bagging, thereby improving bagging efficiency and reducing labor intensity; the front end of the fork plate device adopts a V-shaped opening design, which effectively avoids the problem of broken fruit handles in the bagging process.

Owner:好果子农业科技(北京)有限公司

A pneumatic pressing machine for clothing printing and ironing

InactiveCN105177958BEvenly heatedReduce lossesIroning apparatusTextile decorationEngineeringMechanical engineering

The invention discloses a pneumatic pressing and ironing machine for clothing printing and ironing. The pneumatic pressing and ironing machine comprises a rack, a pressing and ironing table, a pressing and ironing device and a clamping device. The pressing and ironing device comprises an upper pressing and ironing plate, a lower pressing and ironing plate and a pressing and ironing air cylinder. The bottom face of the upper pressing and ironing plate is provided with a limiting protruding block, a clamping groove and an air outlet hole. A guiding device is arranged between the upper pressing and ironing plate and the lower pressing and ironing plate. The clamping device comprises a clamping air cylinder, an upper air clamp and a lower air clamp. The pneumatic pressing and ironing machine is simple in structure and high in practicality; by means of design of the guiding device, pressing precision between the upper pressing and ironing plate and the lower pressing and ironing plate is higher, and the quality of clothing pressing and ironing is improved; meanwhile, as the limiting protruding block and the limiting groove are matched, the situation that the two pressing and ironing plates are dislocated can be prevented, the production efficiency of the pressing and ironing machine is improved by means of the clamping device, the lower air clamp can have effects of fixing and supporting the lower pressing and ironing plate, the parallelism between the lower pressing and ironing plate and the upper pressing and ironing plate is guaranteed, and comprehensive utilization efficiency is improved.

Owner:无锡市和田服饰有限公司

New claw device

ActiveCN105522309BImprove welding qualityEven by forceFinal product manufactureWelding/cutting auxillary devicesWaste managementWelding

The invention discloses a novel pressing claw device, which includes a pressing plate, a driving part for driving the pressing plate, several pressing jaws located under the pressing plate, and a base for carrying various parts. There are installation parts for installing the pressure claws at intervals between the seats, and installation gaps are formed between adjacent installation parts; installation bosses are arranged at intervals at the rear of the opposite side of the installation parts, which are located at the junction of the installation part and the installation gap, and the adjacent installation bosses A mounting concave platform is formed between them; the tail of the pressing claw is provided with a snap-in element, and the snap-in element snaps in from the installation gap; one or two pressure claws are snapped into the installation gap, and the snap-in end of the snap-in element is placed on the installation protrusion On the platform or on the installation concave platform; the pressure claw is rotatably connected to the installation part; the new pressure claw device provided by the present invention has a more accurate crimping position, a more suitable pressing force, and has high compatibility, adapting to multiple specifications of batteries Chip crimping work, improve product quality.

Owner:SUZHOU AUTOWAY SYST

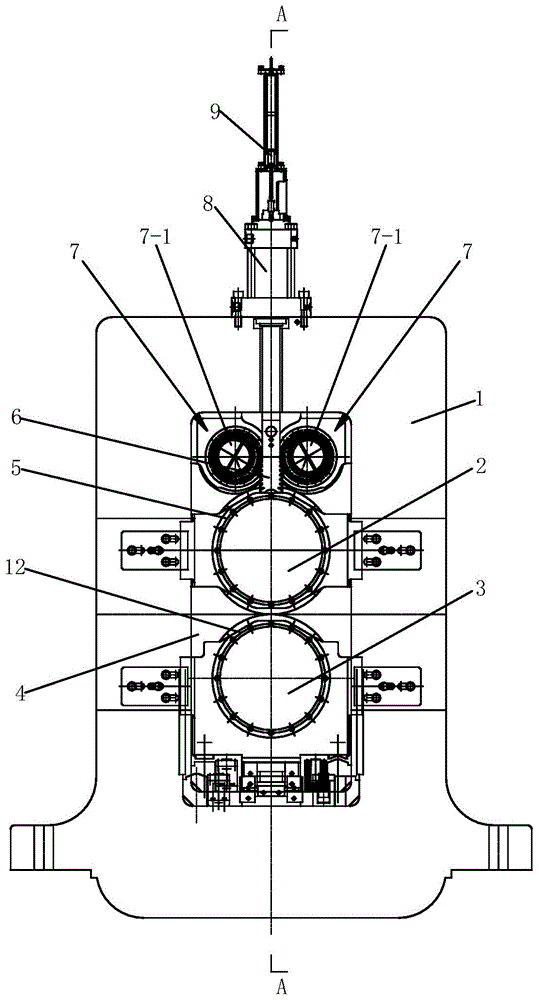

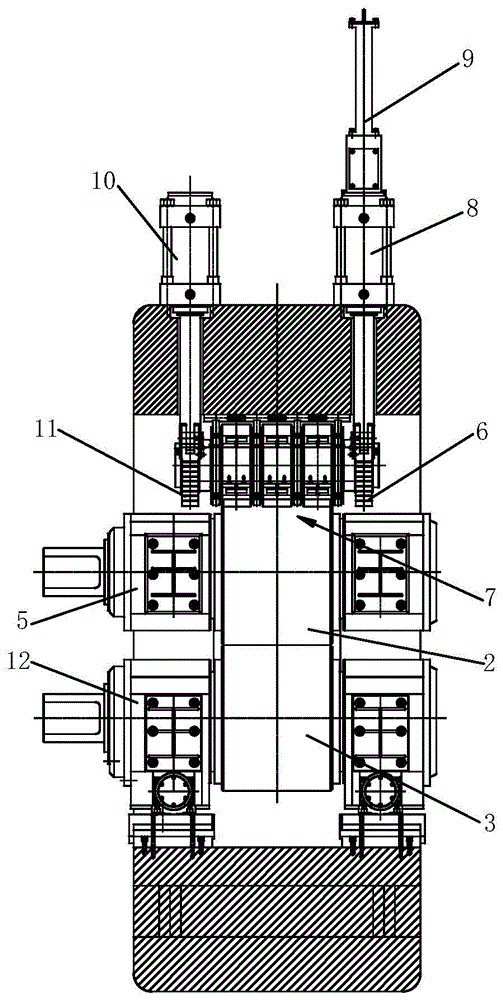

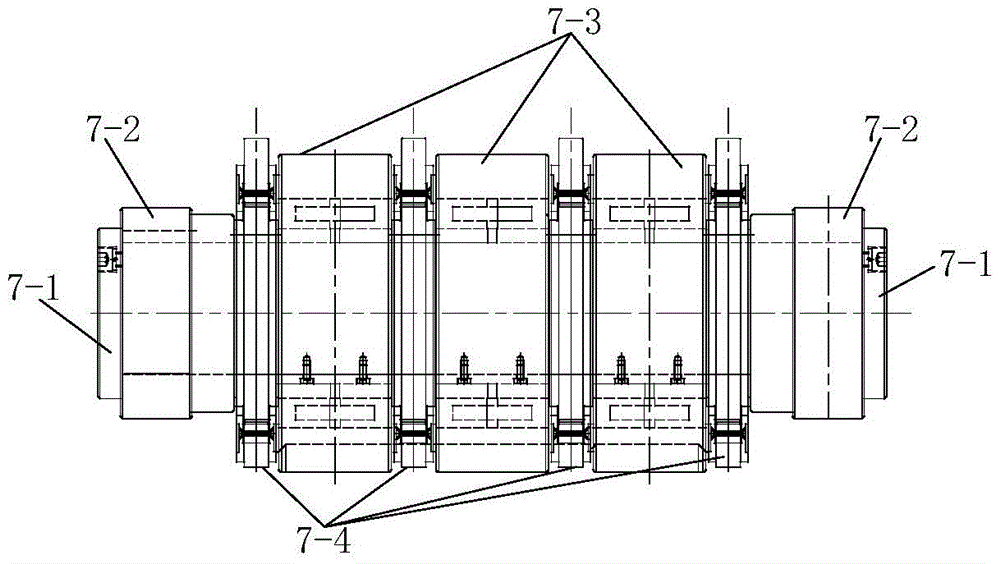

An integral arch type four-high rolling mill

ActiveCN104492813BSimple structureNovel and reasonable designMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderPiston rod

Owner:XIAN JIERUI PRECISION METALLURGICAL EQUIP

An automatic pressing mechanism for earphones

ActiveCN103634732BReduce labor intensityImprove pressing accuracyElectrical transducersCushioningEngineering

Owner:BOZHON PRECISION IND TECH CO LTD

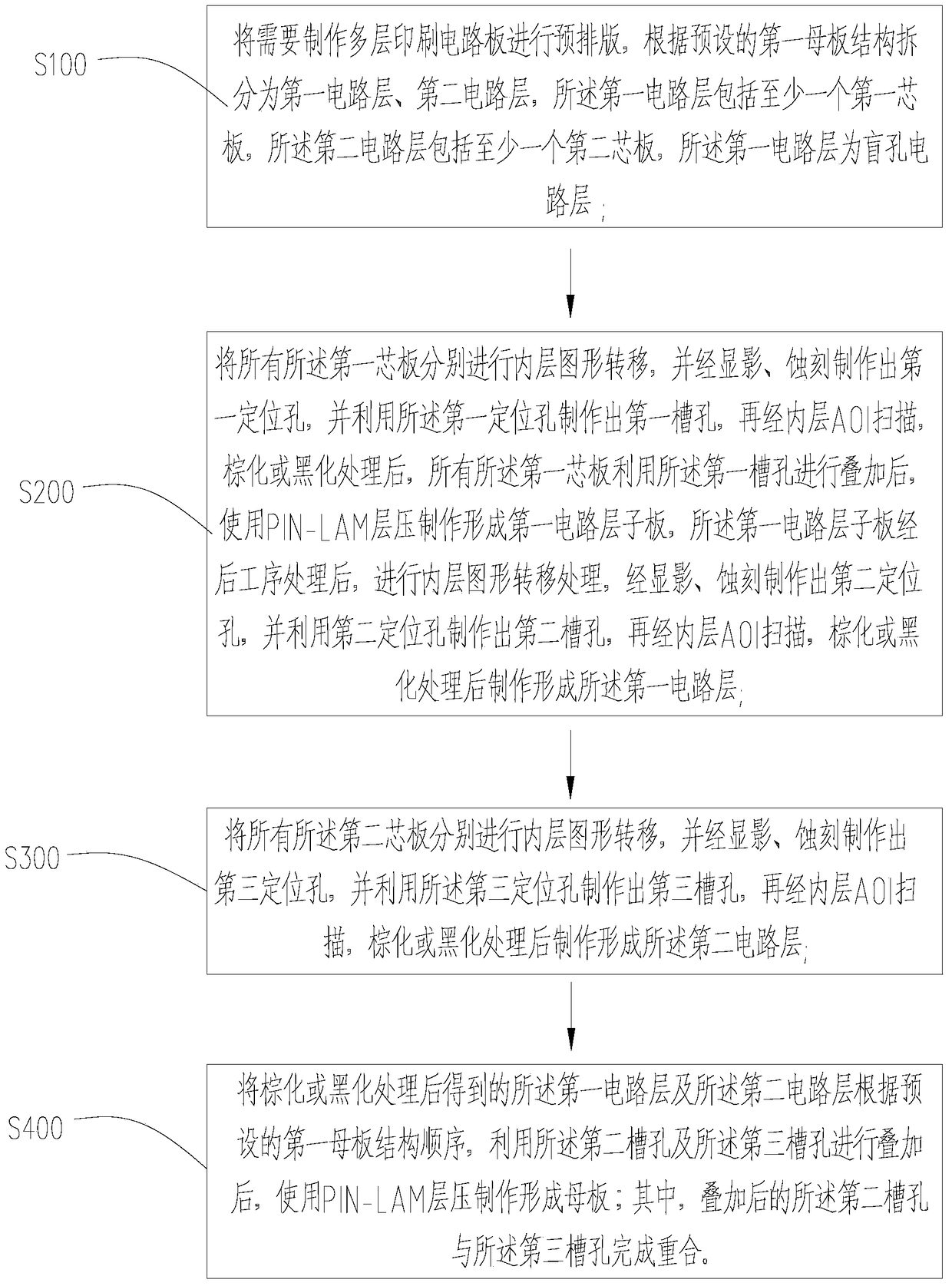

Manufacturing method of multilayer printed circuit board and multilayer printed circuit board

ActiveCN105430944BAvoid Position Accuracy ImpactAvoid the effects of expansion and contractionPre-fabricated insulating pattern transferMultilayer circuit manufactureEngineeringPrinted circuit board

The invention relates to a manufacturing method for a multi-layer printed circuit board and the multi-layer printed circuit board. The manufacturing method for the multi-layer printed circuit board comprises the following steps of: performing inner layer pattern transfer on all first core boards, forming a first groove hole by utilizing a first positioning hole formed by development, laminating all the first core boards by utilizing the first groove hole to form a first circuit layer sub-board, and forming a second groove hole; and performing inner layer pattern transfer on all second core boards, forming a third groove hole by utilizing a third positioning hole formed by development, performing superposition according to a preset first motherboard structure order, and laminating a first circuit layer and a second circuit layer to form a motherboard. According to the manufacturing method for the multi-layer printed circuit board, the alignment precision of multi-time lamination is improved and the press-fit precision of the multi-layer printed circuit board is enhanced.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

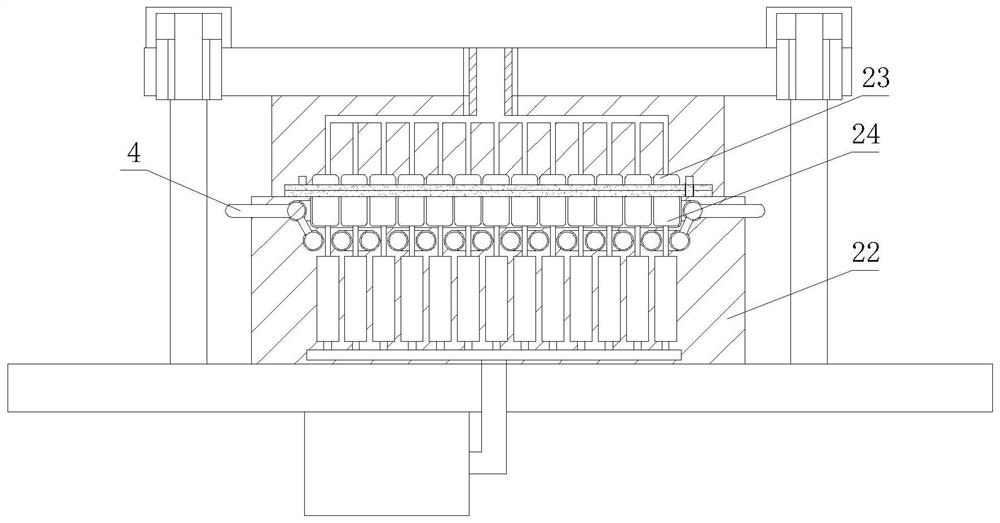

Multifunctional pressing jig

PendingCN110061404AReduce manufacturing costReduce labor costsContact member assembly/disassemblyEngineeringMechanical engineering

The present invention provides a multifunctional pressing jig, comprising a lower die base assembly, an upper die base assembly, a lower die assembly and an upper die assembly. The present invention provides a multifunctional pressing jig capable of pressing a conductive terminal or a grounding terminal into a connector housing separately or simultaneously pressing the conductive terminal and thegrounding terminal into the connector housing, thereby realizing the requirement of combining two stations into one station and simultaneously reducing the production cost and labor cost of the jig. Finally, the effect of improving the production efficiency and shortening the manufacturing cycle of the product are achieved. The jig is highly compatible and highly precise in pressing.

Owner:FCI CONNECTORS DONGGUAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com