An integral arch type four-high rolling mill

A four-high rolling mill and archway technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of low pressing precision, and achieve high pressing precision, high working reliability, convenient The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

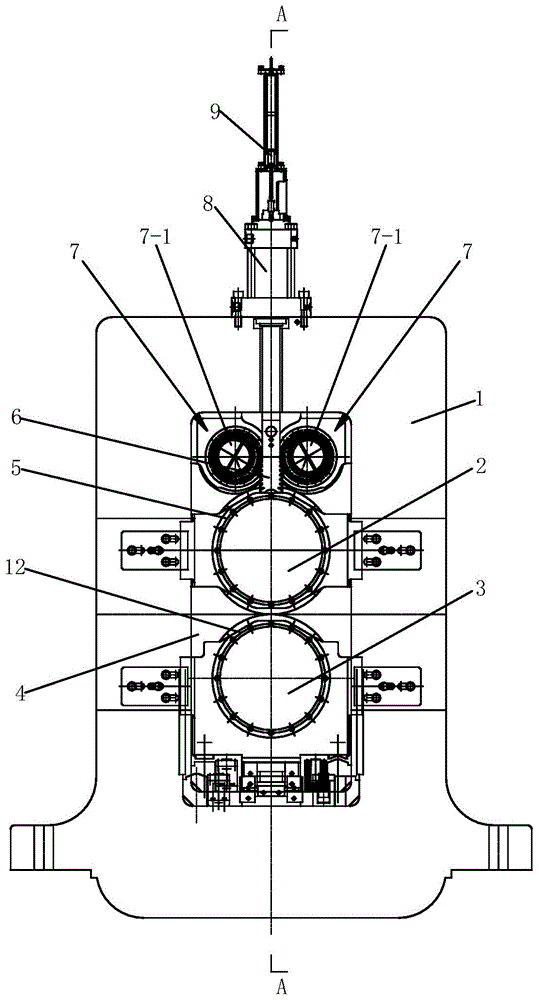

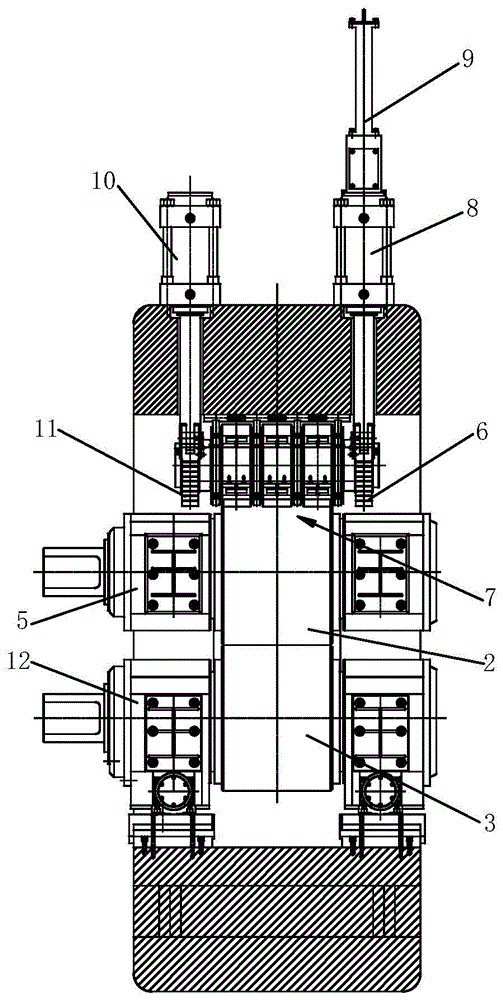

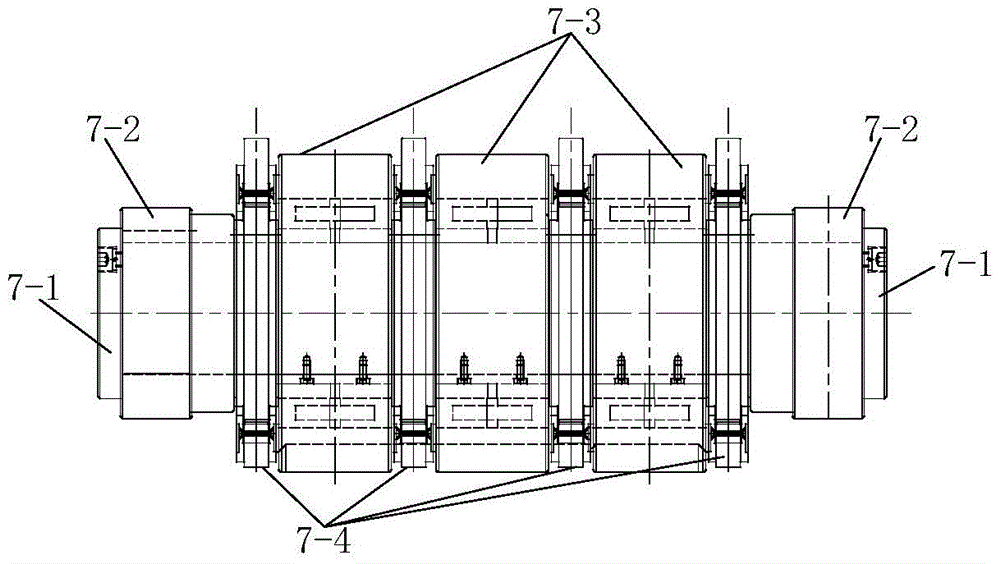

[0028] Such as figure 1 , figure 2 and image 3 The overall archway-type four-roll rolling mill shown includes an archway 1 and an upper work roll 2 and a lower work roll 3 connected to the archway 1 and parallel to each other. Both sides of the archway 1 are provided with rectangular The window 4, the upper work roll 2 and the lower work roll 3 are slidingly connected with the rectangular window 4, and two backing rolls 7 for pressing the upper work roll 2 are arranged above the upper work roll 2 , the two backing rolls 7 all include a central shaft 7-1 and a plurality of saddles 7-4 arranged on the central shaft 7-1, two eccentric gears 7-2 and are used to connect with the upper working roll 2. A plurality of rolling sleeves 7-3 that are in contact with each other. The two eccentric gears 7-2 are respectively installed on the two ends of the central shaft 7-1. The saddle seat 7-4 is fixedly connected with the archway 1. The saddle The seat 7-4 is in rotation with the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com