Cold storage plate production system

A production system and cold storage board technology, applied in applications, household appliances, flat products, etc., can solve the problems of low plastic foam quality, affecting product quality, poor work efficiency, etc., achieve high lamination precision, reliable quality, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

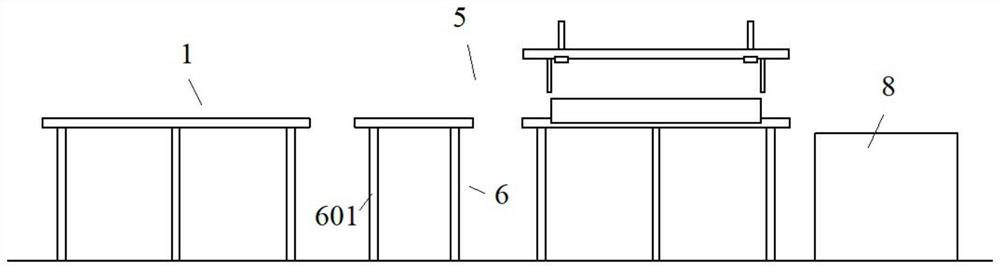

[0026] Such as figure 1 As shown, a cold storage panel production system includes a cutting device 1 , a laminating device 5 and a foaming glue injection device 8 arranged in sequence.

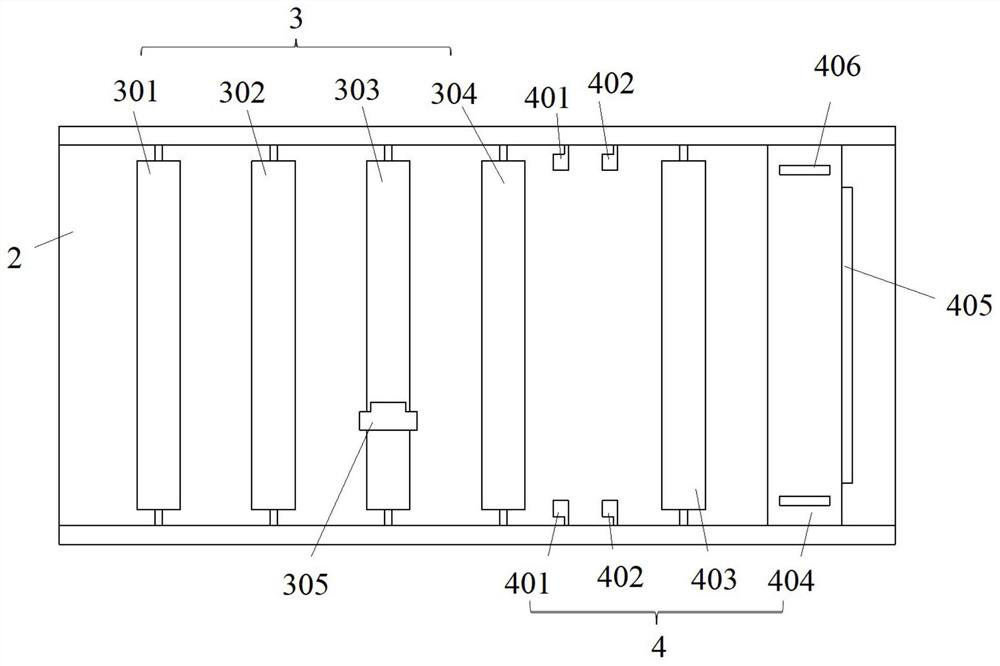

[0027] Such as figure 2 As shown, the cutting device 1 includes a frame 2 and a rough cutting module 3 and a fine cutting module 4 which are sequentially arranged on the frame 2. The vertical first conveying roller 301, paired grinding roller 302 ( figure 2 Among them, one grinding roller 302 is covered by another grinding roller 302), cutting roller 303 and second conveying roller 304, and the first cutting knife 305 is movable on the cutting roller 303, and the fine cutting module 4 includes a plurality of pairs and is arranged on Cutter, the 3rd delivery roller 403 and hold-down plate 404 on frame 2 both sides, cutter is located between the second delivery roller 304 and the 3rd delivery roller 403, and cutter comprises the first cutter for pre-cutting 401 and the second cutter 402 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com