Forming curing mold for plastic-sealed diode production and implementation method of forming curing mold

A technology for curing molds and diodes, which is applied in household appliances, other household appliances, applications, etc., can solve the problems of easily damaged diodes, easy overflow of insulating materials, troublesome mold taking, etc., to reduce waste of water resources, improve demoulding efficiency, Effect of preventing leakage of injection molding liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

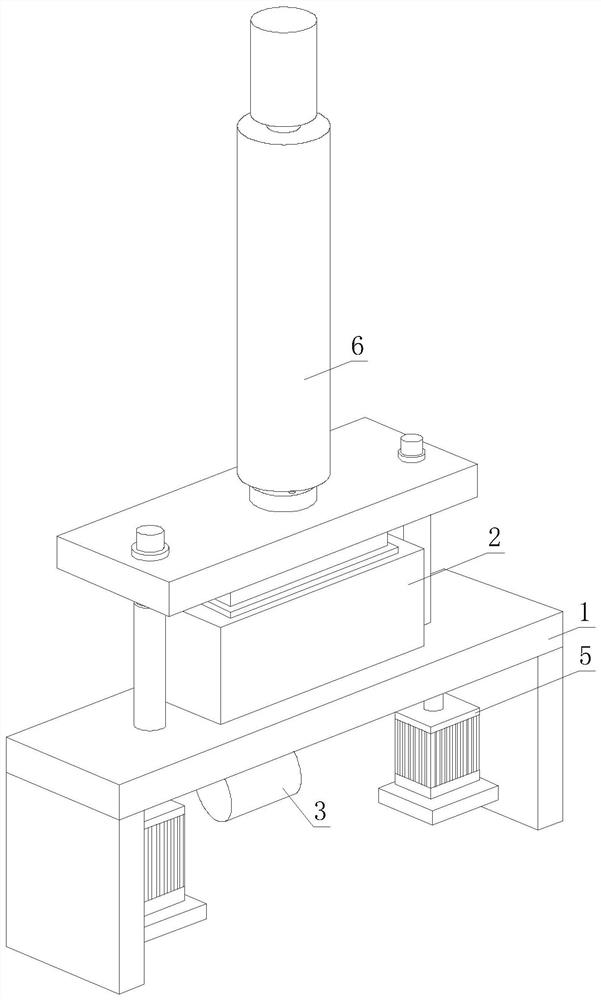

[0042] In order to better demonstrate the implementation process of the molding and curing mold for the production of plastic-encapsulated diodes, this embodiment proposes a method for implementing the molding and curing mold for the production of plastic-encapsulated diodes, including the following steps:

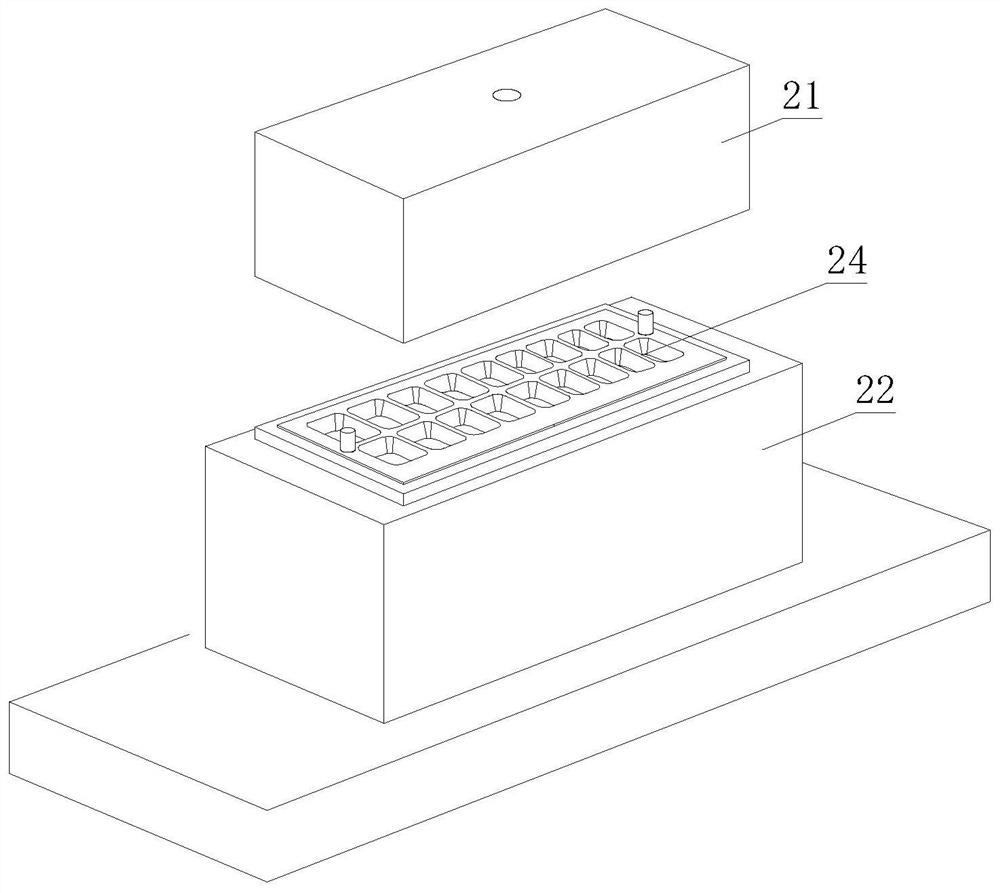

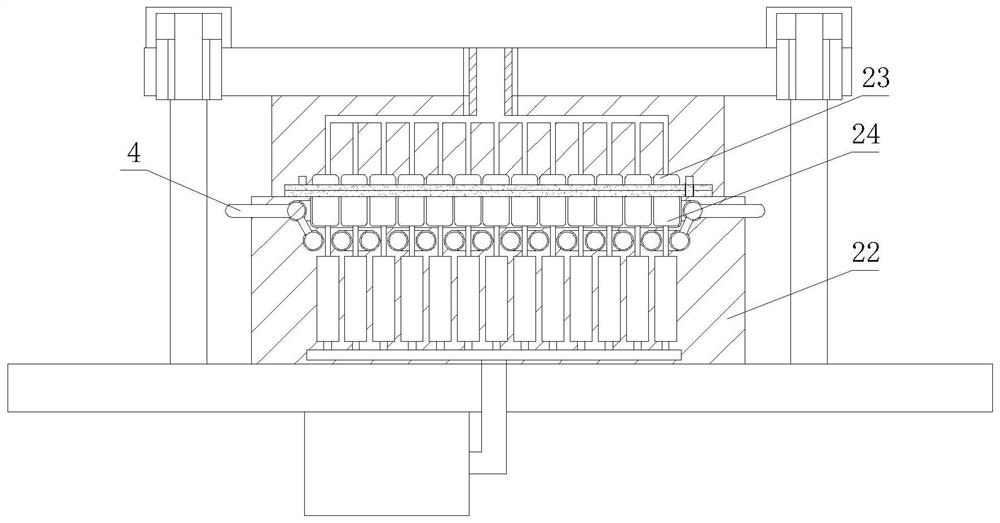

[0043] Step 1: Place the object to be plastic-sealed in the lower mold groove 24 from the packaging placement groove 25, and the upper mold base 21 below the upper pressing plate 53 is driven down by the telescopic rod 52 above the pressing cylinder 51, thereby pressing the upper mold base 21 and the lower mold base. Die base 22 is pressed and closed;

[0044] Step 2: After the upper mold base 21 and the lower mold base 22 are pressed together, the screw 63 is rotated to drive the piston 65 to extrude the injection molding in the injection pipe 61, and the injection liquid is squeezed into the main injection groove 671, and a plurality of injection shunt grooves 672 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com