Full-automatic anchor chain gear pressing machine and gear pressing method

An anchor chain press, fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of failure to achieve automation, low control accuracy of the anchor chain press, and improve the degree of automation. , The effect of uniform force and improving the accuracy of the pressure file

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

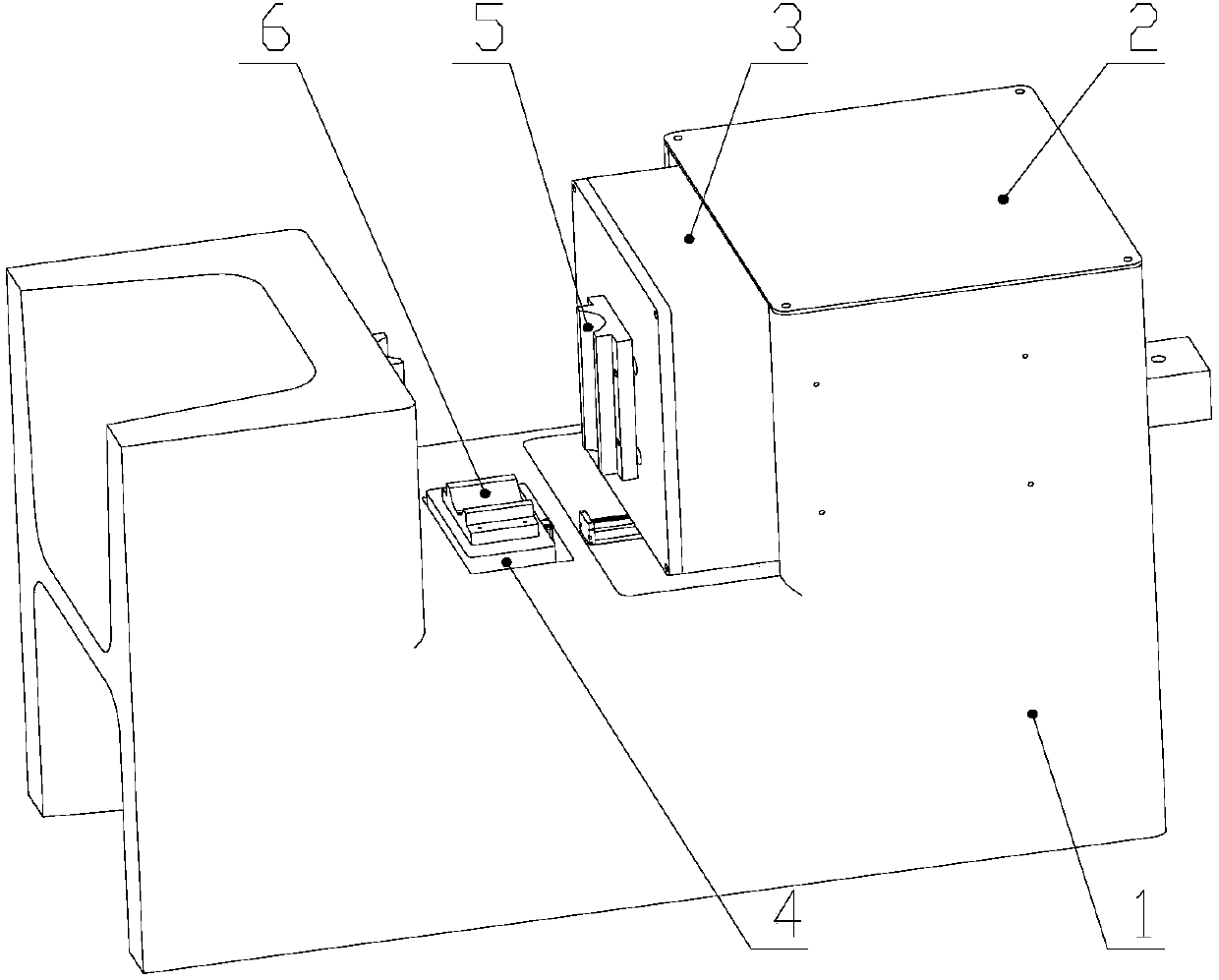

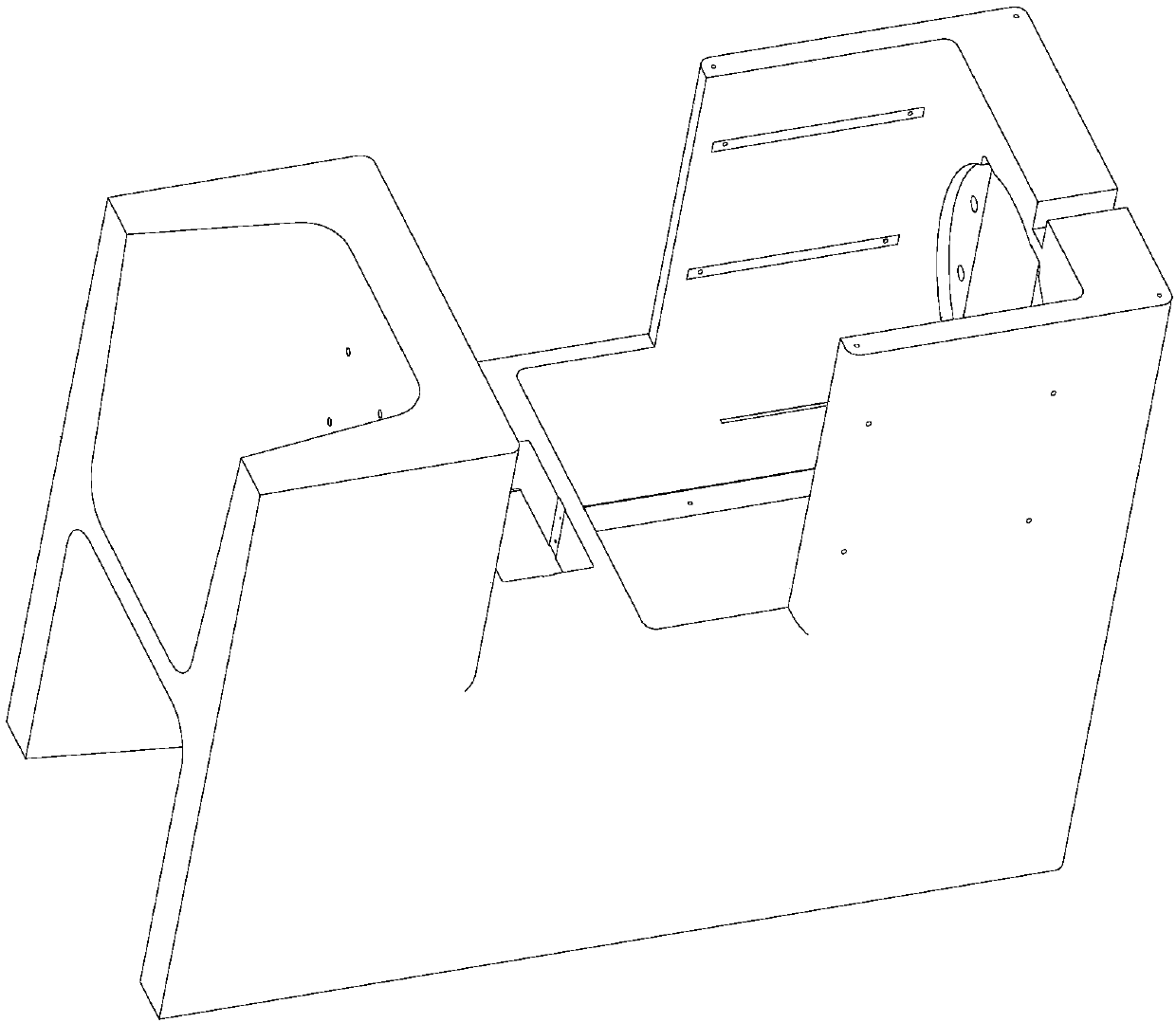

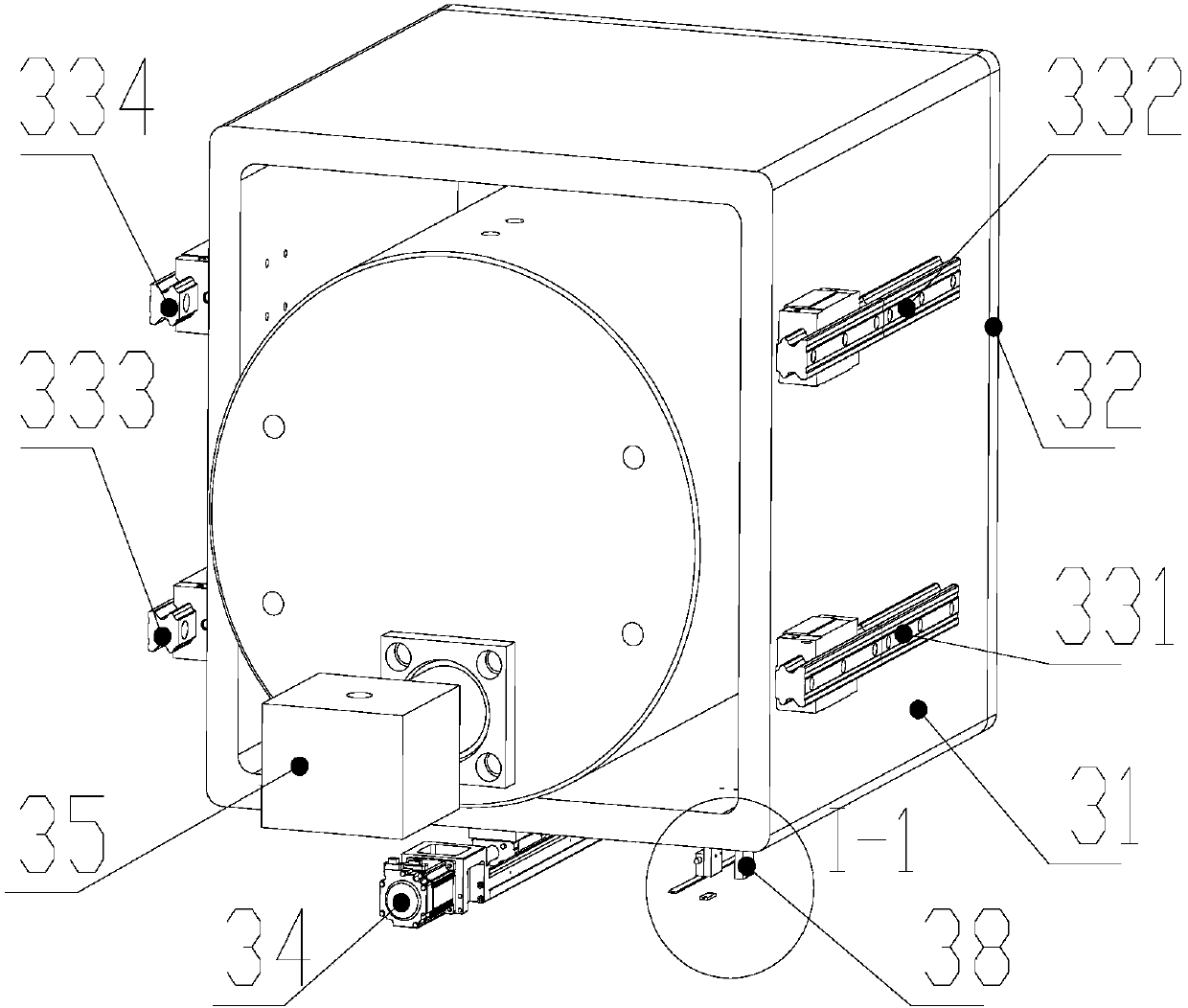

[0029] Such as Figure 1 to Figure 5 As shown, a fully automatic anchor chain presser of the present invention includes a fuselage 1, an upper cover plate 2 of the fuselage, a presser mechanism 3, an anchor chain support mechanism 4, a transverse mold 5 and a longitudinal mold 6. The fuselage 1 is concave as a whole, and the raised part at the right end is hollowed out, leaving three sides, the front, the rear and the right. There is a rectangular slot I in the middle of the bottom right end of the fuselage 1, and the pressing linear module 34 is installed in the rectangular slot I by screws, and a rectangular slot II is opened on the side for installing the magnetic strip 362 of the magnetic scale 36 , and there is a threaded hole next to it for installing the first proximity switch 37; there is a circular groove on the right side of the right end of the fuselage 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com