Automatic press-fitting mechanism for earphones

A pressing mechanism and earphone technology, applied to electrical components, sensors, etc., can solve problems such as unguaranteed quality, low work efficiency, and high labor intensity, and achieve high pressing accuracy, reduce labor intensity, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

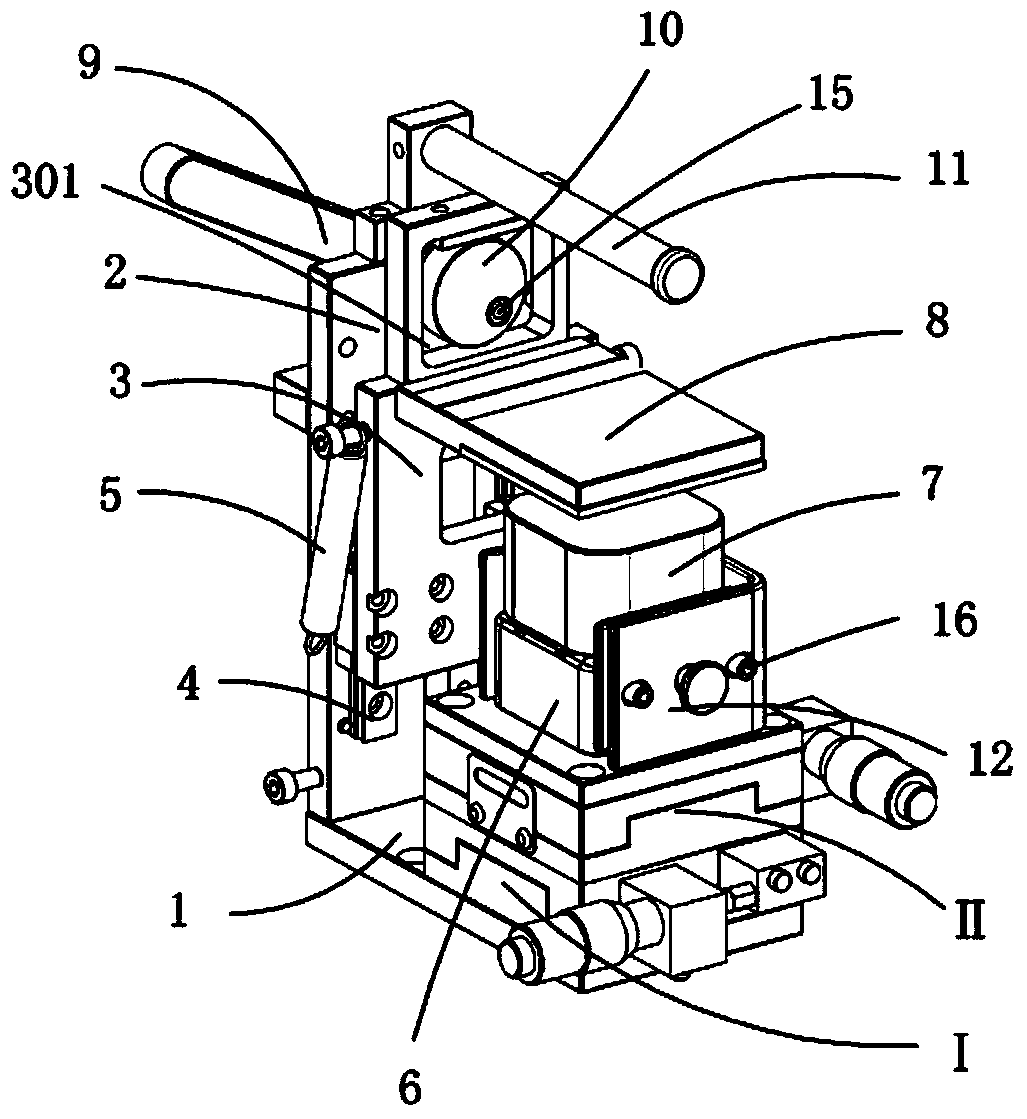

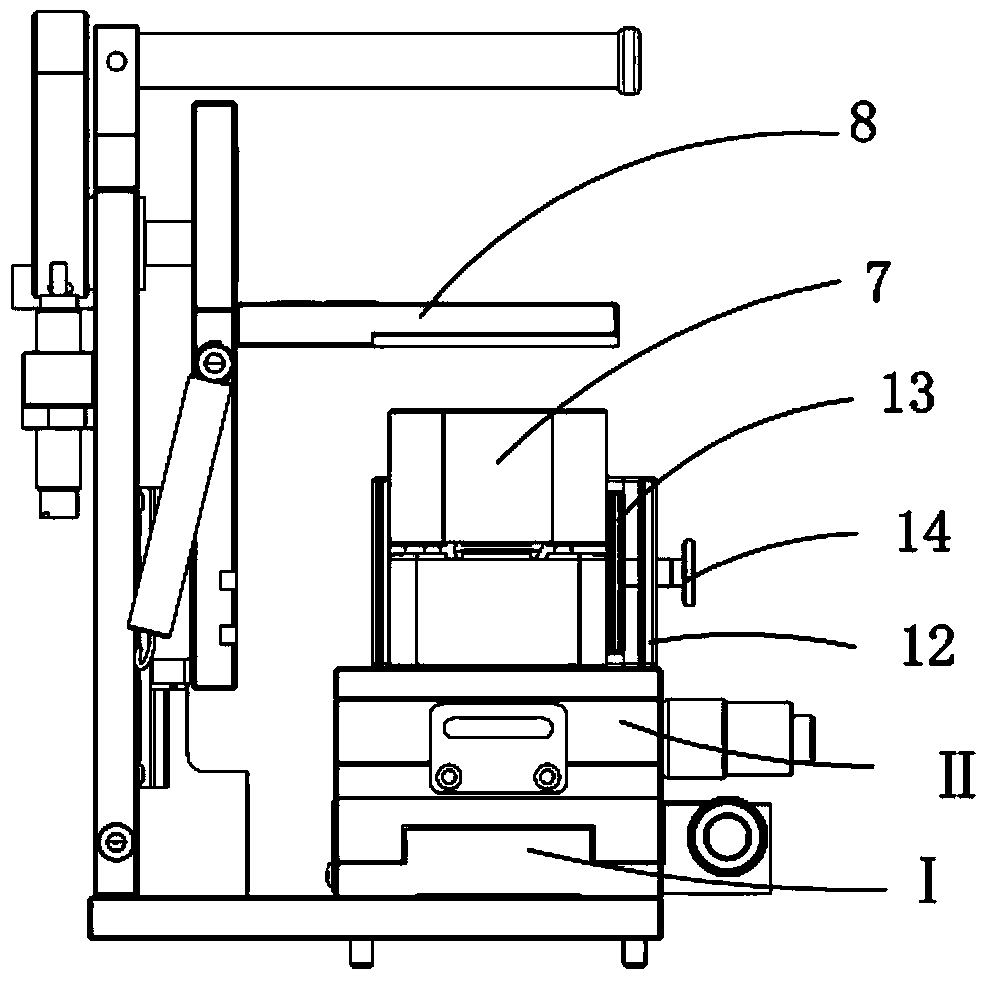

[0017] Examples, see attached figure 1 and 2 , an automatic pressing mechanism for earphones, which includes a base plate 1, a rear vertical plate 2, a sliding plate 3, a slide rail 4, a spring 5, left and right adjustment components I, front and rear adjustment components II, a lower pressing block 6, an upper pressing block 7, Pressing plate 8, position handle 9, eccentric wheel 10, handle 11 and alignment adjustment device, said alignment adjustment device includes U-shaped plate 12, elastic pressure block 13 and adjustment knob 14, and said rear vertical plate is installed vertically on the base plate The rear part; the rear vertical plate is provided with a slide rail, and the sliding plate is installed on the sliding rail through a slider; a spring is connected between the sliding plate and the rear vertical plate for buffering; the upper part of the sliding plate is provided with a square slot hole 301, the position handle is installed behind the rear vertical plate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com