A keyboard with an "I" shape keycap integrally formed by injection molding

A shape and keycap technology, applied in emergency actuators, calculations, electrical components, etc., can solve the problems of high production cost and troublesome assembly, and achieve the effect of beautiful product shape, high pressing precision, and smooth key surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

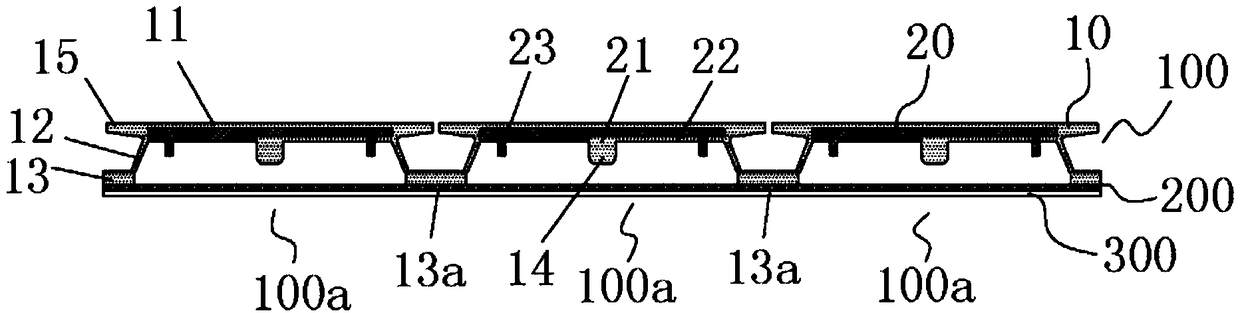

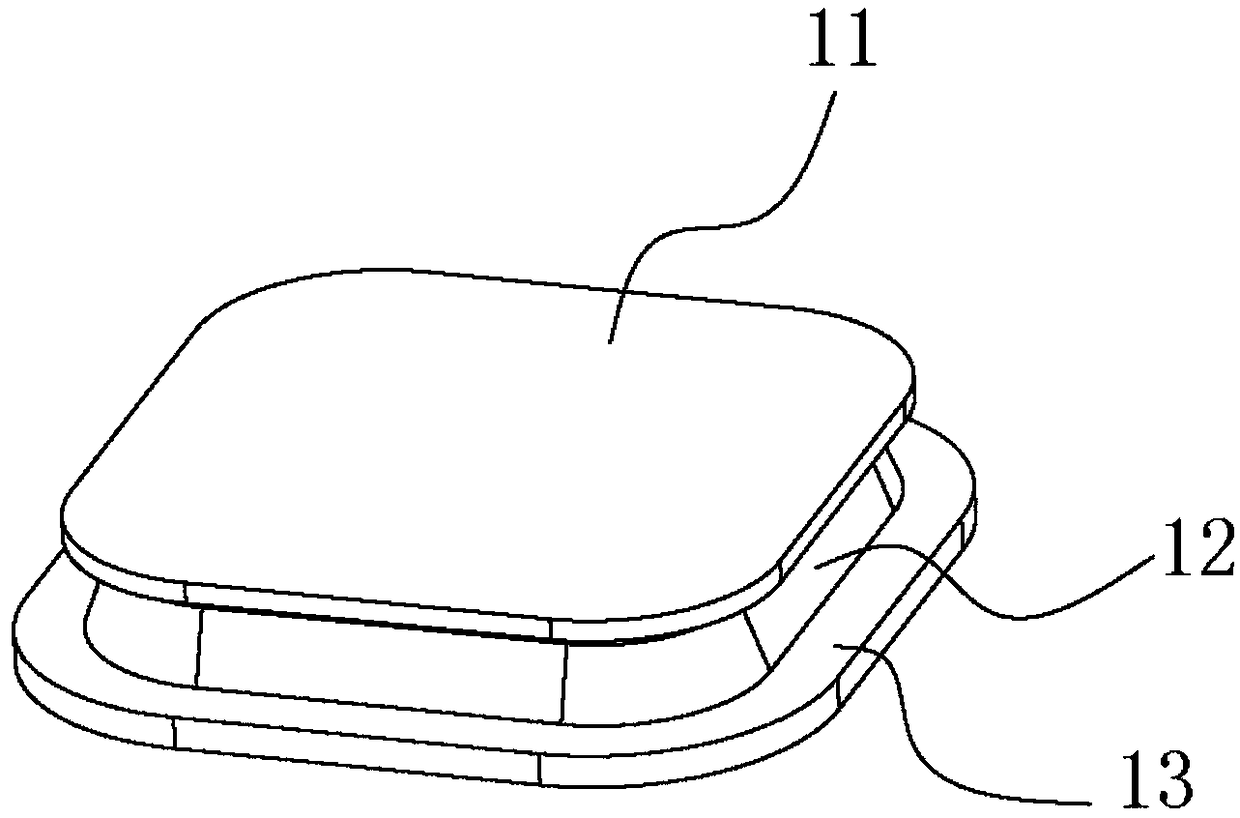

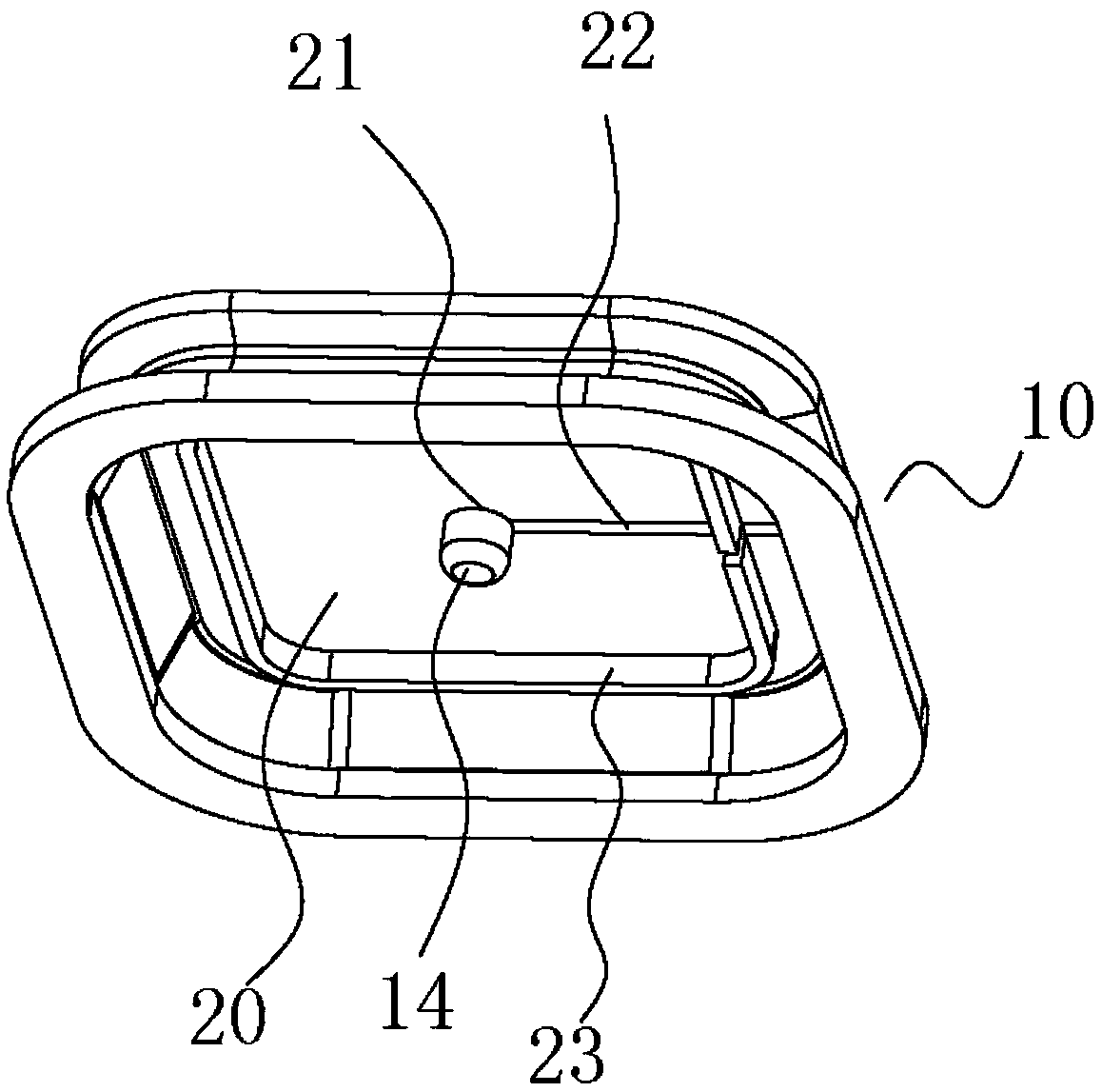

[0027] Such as Figure 1-6 As shown, a keyboard of the present invention with an "I"-shaped keycap integrally formed by injection molding includes an integrated "I"-shaped keycap 100 and a printed circuit located under the integrated "I"-shaped keycap 100. a membrane 200 and a keyboard chassis 300 supported under the printed circuit membrane 200;

[0028] The one-piece "work" shape key cap 100 is formed by integral injection molding of soft rubber 10 and several hard sheets 20, wherein each hard sheet 20 corresponds to a key unit 100a, and is located at the center of the bottom surface of each hard sheet 20. Have a concave body 21 that does not penetrate the surface of the hard sheet 20, and have a concave guide groove 22 that does not penetrate the surface of the hard sheet 20 from the edge of any side of the bottom surface of the hard sheet 20, and the concave guide groove 22 is connected to the surface of the hard sheet 20. The concave bodies 21 communicate with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com