Liquid crystal display COF (chip on film) bonding semi-automatic device and pressing process thereof

A liquid crystal display, semi-automatic technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of difficulty in pressing the Gate side and the Source side at the same time, difficult to achieve, etc., to improve the accuracy, improve the pressing accuracy, and ensure the plane degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

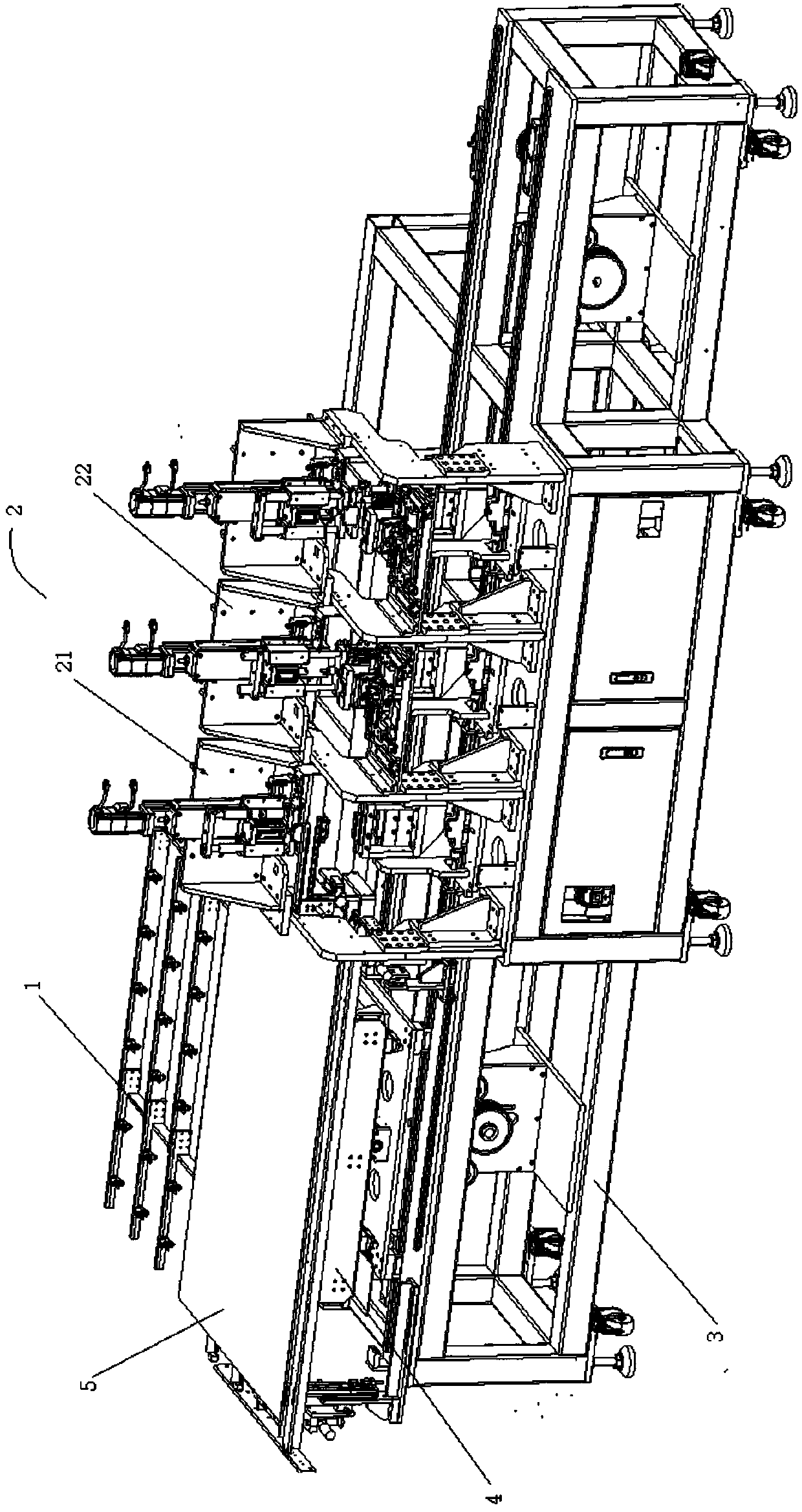

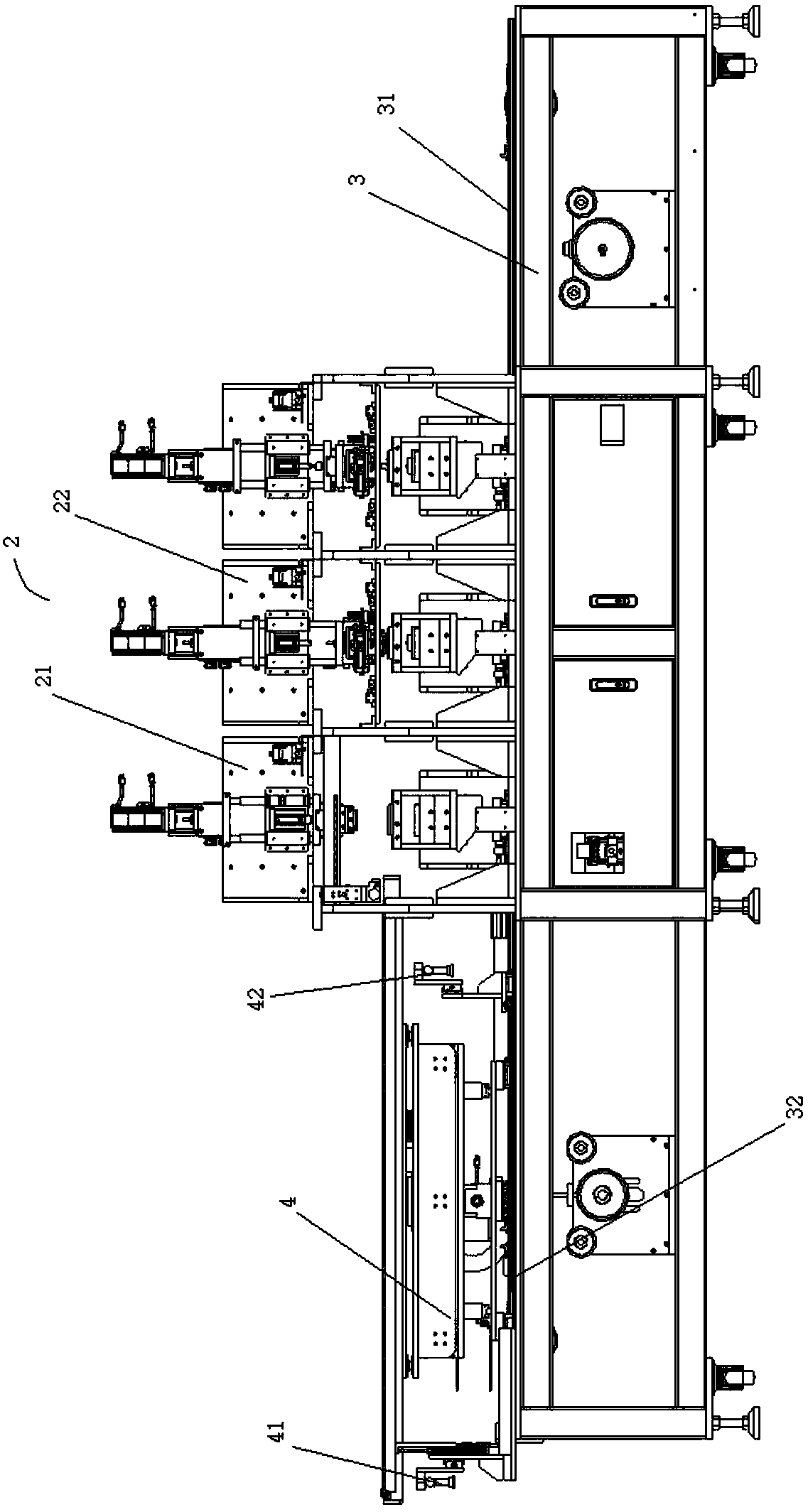

[0049] In order to solve the problems existing in the prior art that it is difficult to press the Gate side and the Source side at the same time, and it is difficult to realize the pressing of a large-size LCD screen while ensuring the flatness of the LCD screen, and it is difficult to manually adjust the position of the LCD screen. The problem of ensuring positional accuracy. The invention provides a semi-automatic device for liquid crystal display COF pressure.

[0050] The device includes a vacuum adsorption mechanism 1 for adsorbing a liquid crystal display 5, and the size of the liquid crystal display is not greater than 75 inches.

[0051] Preferably, the vacuum adsorption mechanism 1 includes a plurality of vacuum adsorption regions for adsorbing liquid crystal display screens 5 of different sizes, specifically, each vacuum adsorption region is composed of a plurality of vacuum adsorption plates 16 .

[0052] Preferably, in this embodiment, there are 5 vacuum adsorptio...

Embodiment 2

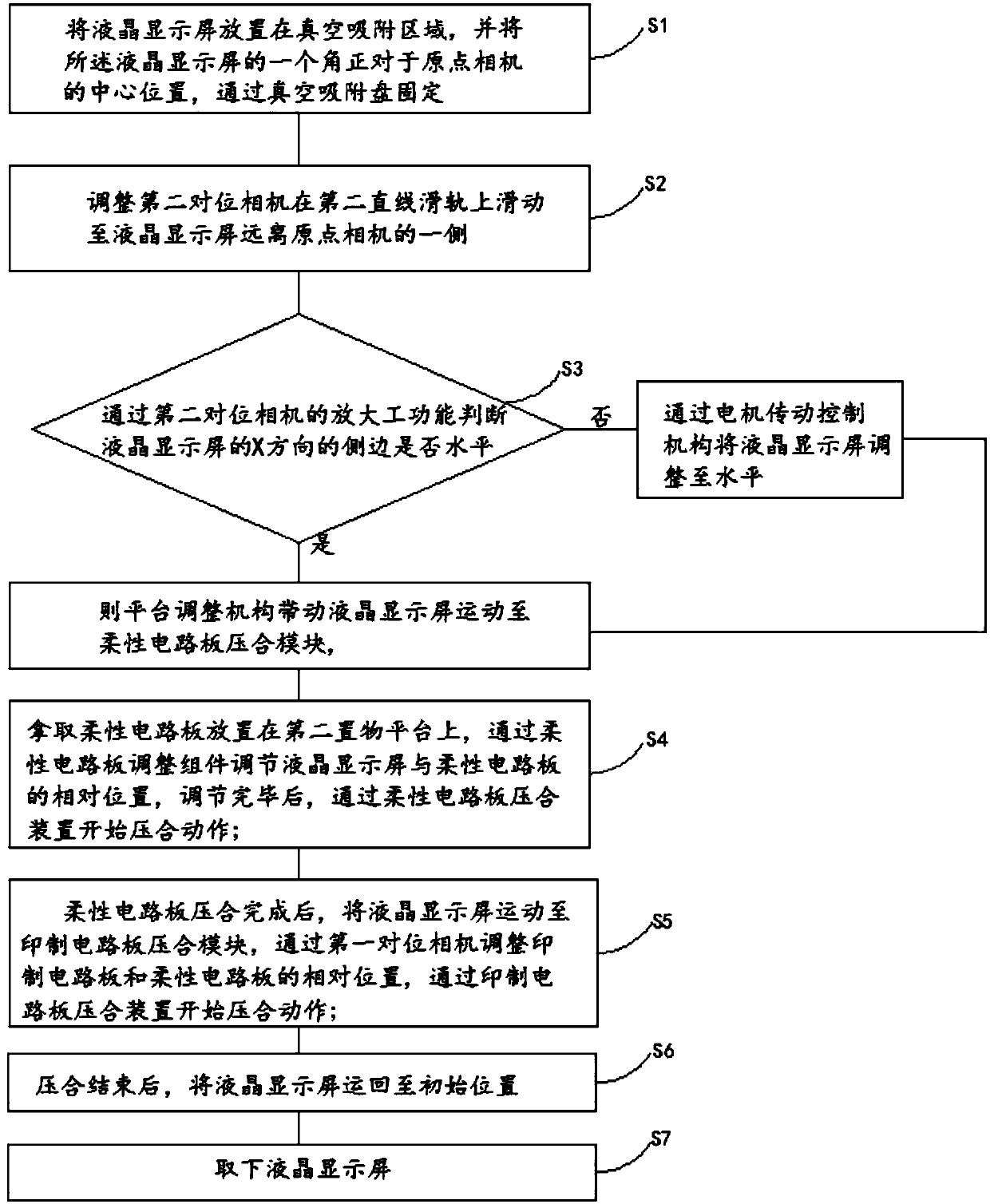

[0065] The present invention also provides a pressing process based on the equipment described in Embodiment 1. Specifically, the operation steps are as follows:

[0066] S1. Place the liquid crystal display 5 in the vacuum suction area, and fix one corner of the liquid crystal display 5 to the center of the origin camera 41 through the vacuum suction plate 16;

[0067]As preferably, in this embodiment, the liquid crystal display screen 5 is placed on the first gas circuit 11, and the control button of the first gas circuit 11 on the touch screen is turned on, and the first gas circuit 11 is connected to complete the process. Describe the adsorption of liquid crystal display screen 5.

[0068] S2. Adjust the second alignment camera 42 to slide on the second linear slide rail 32 to the side of the liquid crystal display 5 away from the origin camera 41;

[0069] S3, judge whether the side of the X direction of the liquid crystal display 5 is horizontal through the magnificatio...

Embodiment 3

[0078] The difference between this embodiment and Embodiment 1 is that in this embodiment, there are three vacuum adsorption regions, forming three gas paths, including the sixth gas path, the seventh gas path and the eighth gas path, and this embodiment Including a flexible circuit board pressing module 22.

[0079] It can be understood that in the above-mentioned embodiments, the number of flexible circuit board pressing modules 22 is at least one, and more than one can be set as required, and one of the flexible circuit board pressing modules can be selected according to the different sizes of the flexible circuit board 11 22 Complete the lamination of the flexible circuit board 11 and the liquid crystal display 5 . As preferably, the number of the printed circuit board pressing modules 21 can also be multiple, and one of the printed circuit board pressing modules 21 is selected according to the size of the required printed circuit board 12 to complete the flexible Pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com