Aluminum pipe bagging device

A bagging device and aluminum tube technology, which is applied to the field of aluminum tube bagging devices, can solve the problems of time-consuming and laborious, unsuitable for large-scale industrial production, and labor costs soaring, so as to reduce labor intensity, improve bagging efficiency and improve efficiency. Economic benefit and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

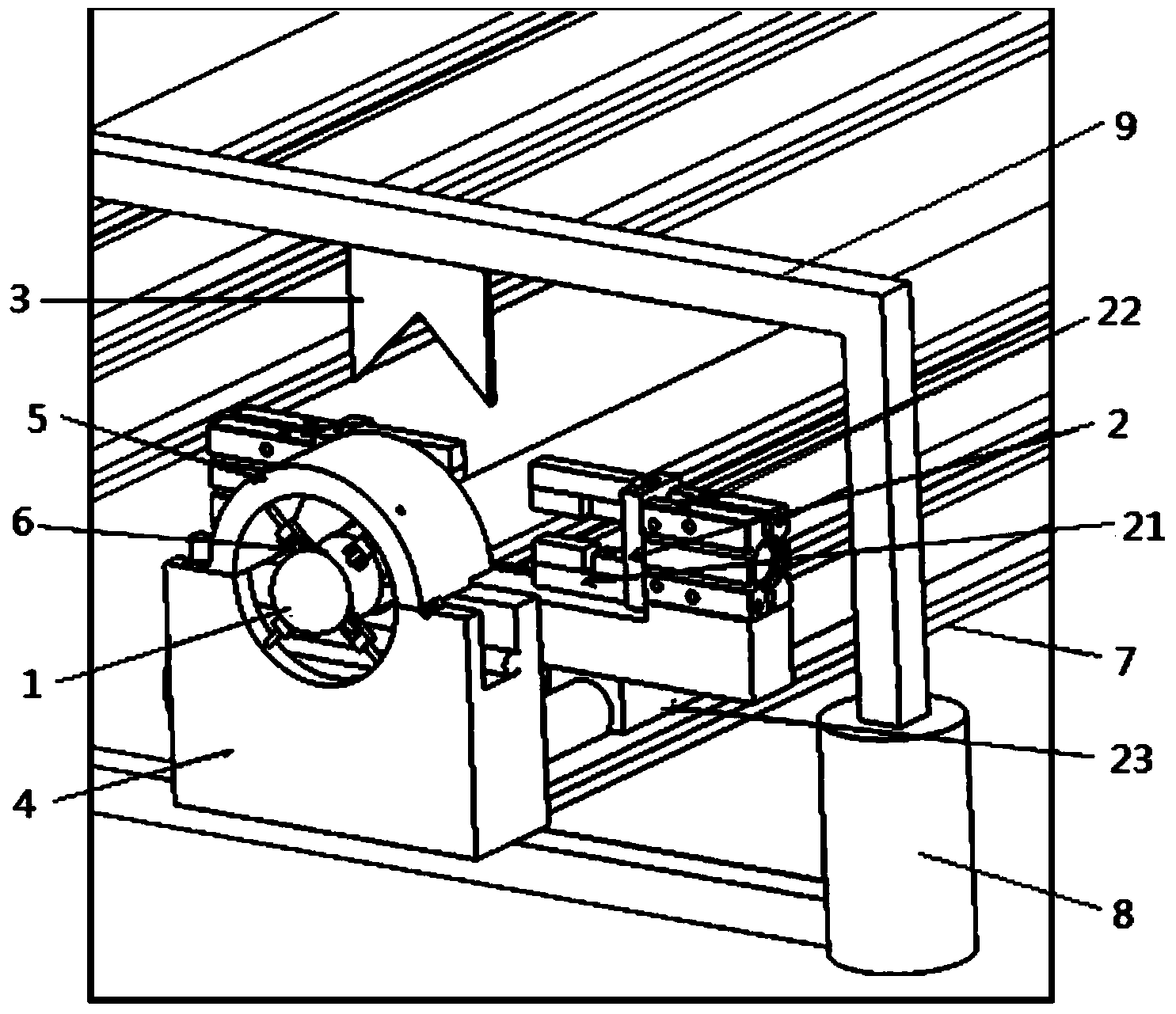

[0018] Embodiment: An aluminum tube bagging device, the front end of the aluminum tube is provided with a guide jig 1 that can stretch the bag, and the rear of the guide jig is provided with a clamp that can clamp the head end of the bag and move along the length direction of the aluminum tube The jig 2 is provided with a cutting knife 3 capable of cutting off the bag above the front end of the aluminum tube.

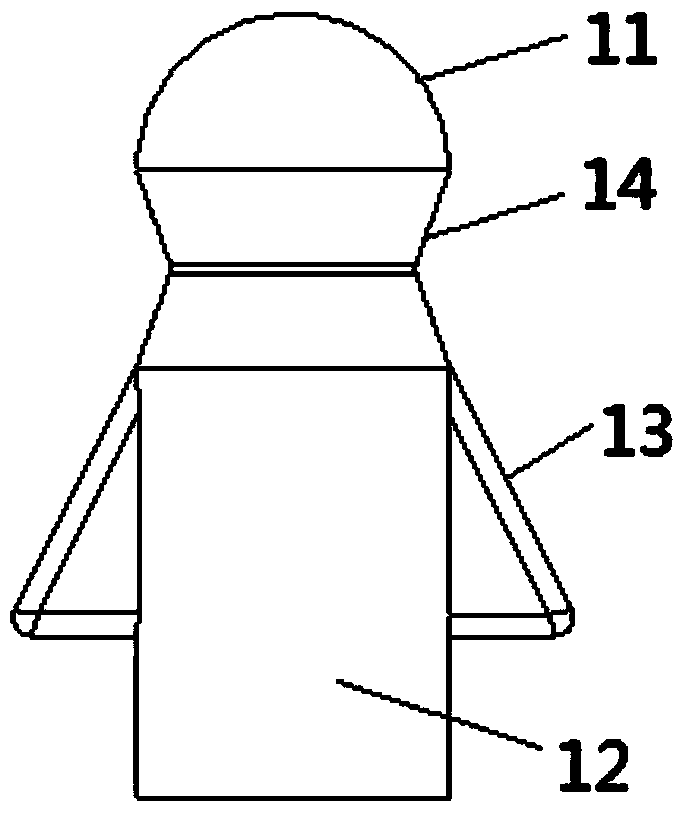

[0019] The guiding jig has a bag sleeve joint 11 and an aluminum tube socket 12, the aluminum tube socket is hollow columnar, the aluminum tube socket is sleeved on the front end of the aluminum tube, and the aluminum tube is socketed The front part of the part is provided with a number of expansion arms 13, and the expansion arms are equally distributed along the radial direction of the socket part of the aluminum tube, and each expansion wall has a radially outward opening from the front to the rear. Open the department.

[0020] The front end of the bag sleeve joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com