Integrated multi-station rotary bag filler of edible fungi cylinder and packing method

An integrated, multi-station technology, applied in packaging, transportation and packaging, packaging item types, etc., can solve problems such as low work efficiency and inability to achieve eight drum cycle loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

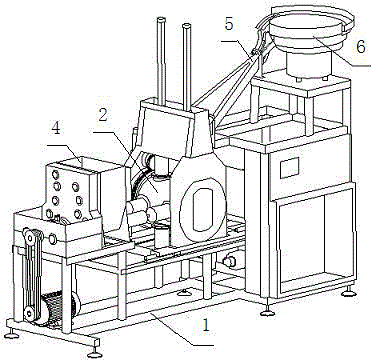

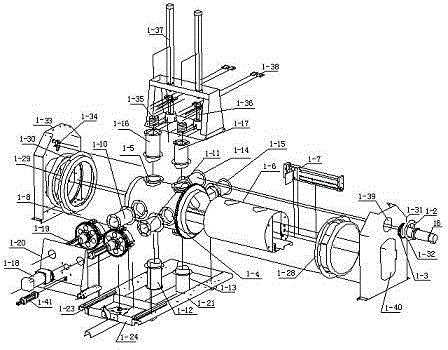

[0050] An edible fungus cylindrical integrated, multi-station, rotary packing device, which consists of: a frame 1, a rotating drum device 2, a socket device 3, and a discharge device 4, the upper part of the frame is connected to the The discharge device, the socket 3, the drum device 2, the drum device has a rotating drum 1-5, the rotating drum has a shaping drum 1-1, the The bottom of the drum device is connected to the sports car frame 1-21, the sports car frame is connected to the socket 3, the drum device is connected to the rod unscrambler 6 through the rod taking device 5, and the discharge device 4 has The screw conveying mechanism is installed in the transmission device.

Embodiment 2

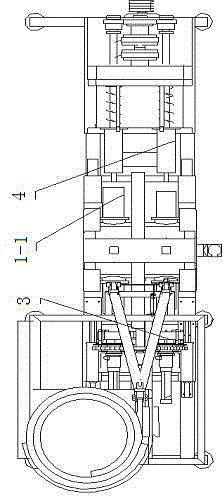

[0052] In the edible fungus cylinder integrated, multi-station, rotary packaging device described in Example 1, the drum device 2 includes a rotating drum 1-5, and the rotating drum has a shaping drum 1-1, which rotates The servo motor 16 is connected to the reduction box 1-2, the reduction box is connected to the driving gear 1-3, the driving gear meshes with the driven gear 1-4, the driven gear is connected to the rotating cylinder 1-5, and the The fixed cylinder 1-6 is inserted into the rotating cylinder, the fixed cylinder is connected to the bag-out cylinder 1-7, the rotating cylinder is connected to the socket device 3, and the socket device is connected to the insert rod cylinder 1-37 and the socket Mouth walking cylinder 1-41.

Embodiment 3

[0054] In the edible fungus cylinder integrated, multi-station, rotary packing device described in Example 2, the said shaping cylinder 1-1 includes a first front cylinder 1-10, a second front cylinder 1-11, a first Lower cylinder 1-12, second lower cylinder 1-13, first rear cylinder 1-14, second rear cylinder 1-15, first upper cylinder 1-16, second upper cylinder 1-17, the rotation The tubes are connected at intervals of 90° to the first front tube 1-10, the second front tube 1-11, the first lower tube 1-12, the second lower tube 1-13, the first rear tube 1-14, and the second rear tube 1-15, the first upper cylinder 1-16, and the second upper cylinder 1-17. That is, each group of binoculars is arranged side by side, and each group of binoculars is separated by 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com