Full-automatic spiral edible mushroom cultivating material bagging machine

A material bagging machine and spiral technology, which is applied in the field of automatic spiral edible fungus culture material bagging machine, can solve the problems of small number of bags, high labor intensity, small amount of material, etc., and can ensure the charging speed. and quality, reduce labor intensity, easy to use and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

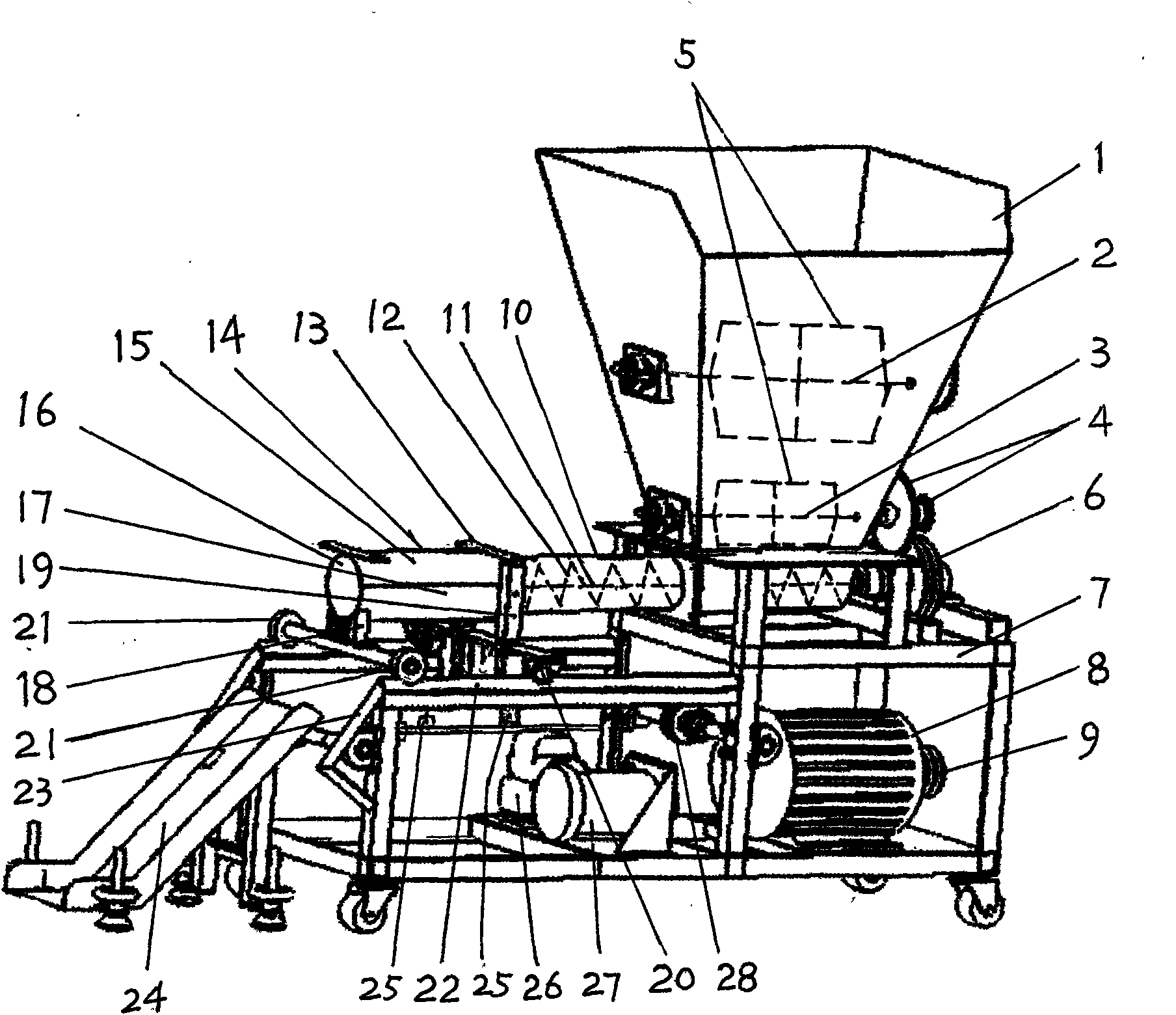

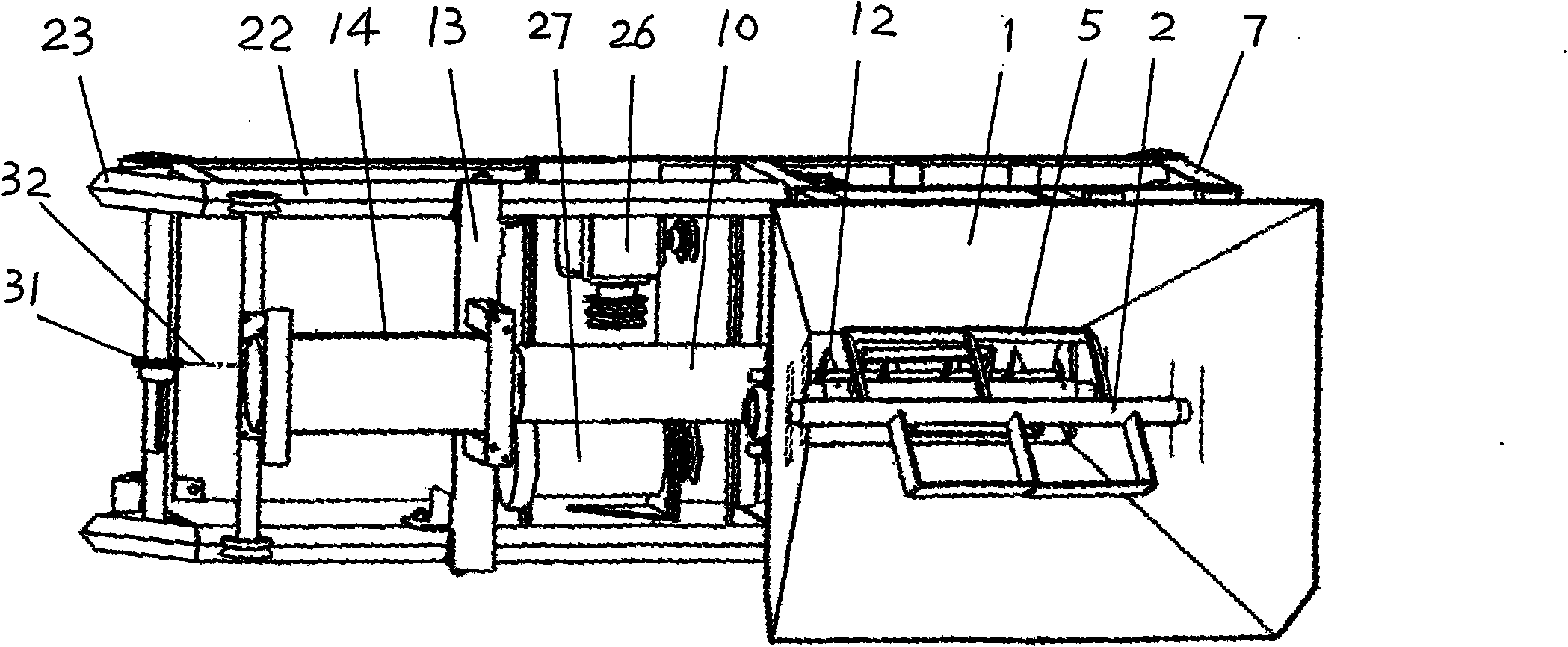

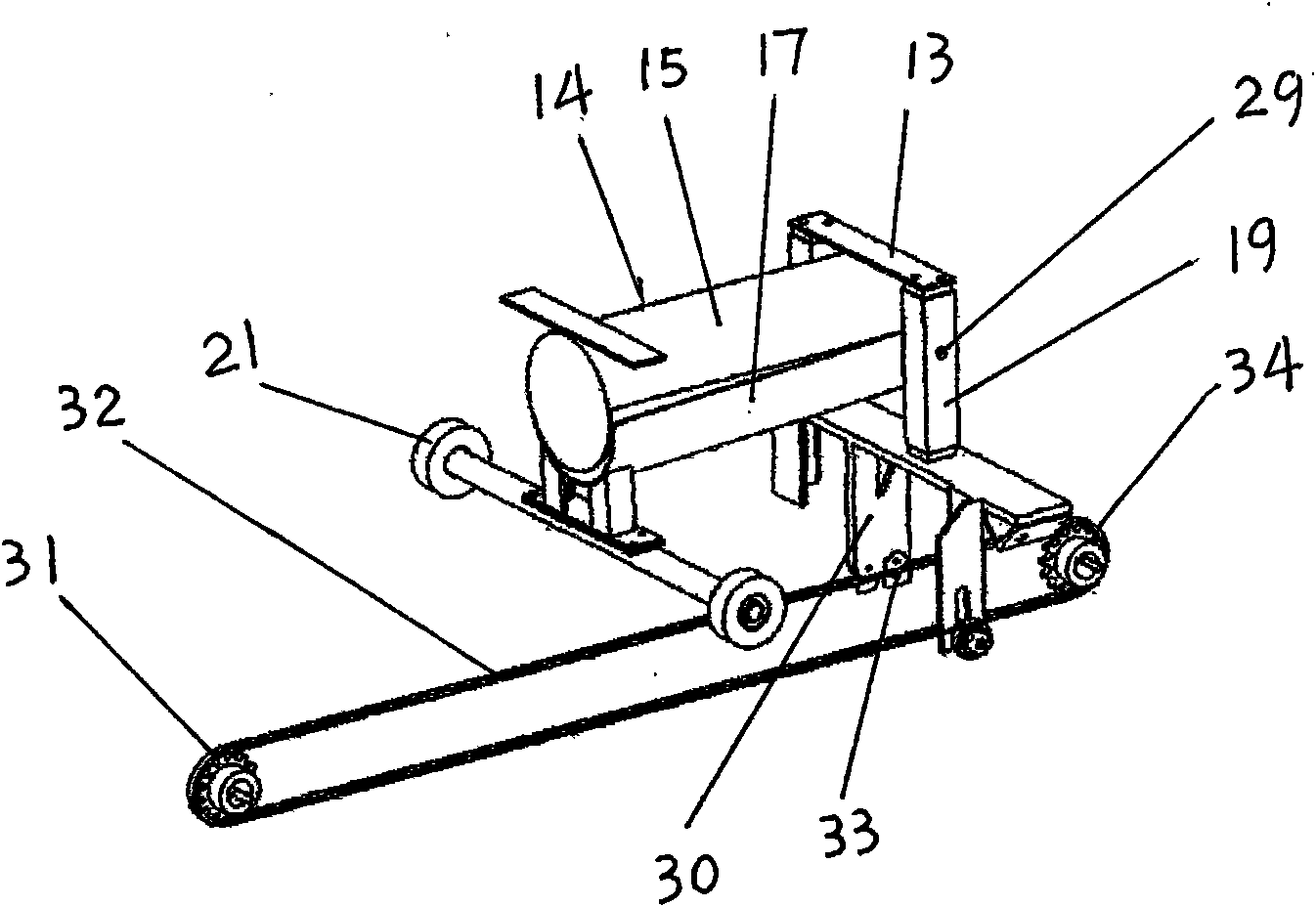

[0024] With reference to the accompanying drawings, it can be seen that the specific parts that make up the bagging machine for edible fungus culture material of the present invention include: 1~feeding hopper, 2~first-level arch breaking stirring shaft, 3~secondary arch breaking stirring shaft, 4~installed on the second The sprocket on the arch-breaking stirring shaft, 5~trapezoidal stirring rod, 6~belt pulley, 7~rack, 8~charging motor for auger, 9~pulley of output shaft of charging motor, 10~discharging Cylinder, 11~ auger shaft, 12~ auger (that is, spiral blade), 13~ sliding trolley, 14~ material bag mold barrel, 15 upper semicircular groove formwork (also known as upper splint), 16~ installed on upper semicircle The stop end cover at the tail end of the trough template, 17~the lower semicircular trough template (also known as the lower splint), 18~the rear frame of the sliding trolley, 19~the front frame of the sliding trolley, 20~set on the front carriage of the sliding tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com