Bagging machine

A bagging machine, packaging bag technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as troublesome bagging and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

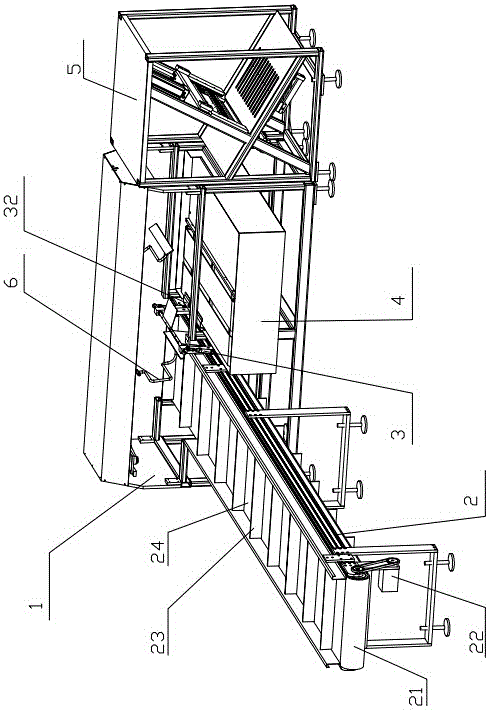

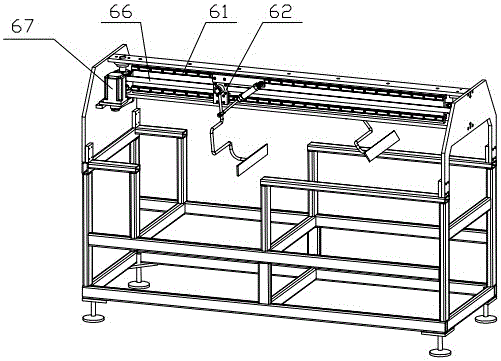

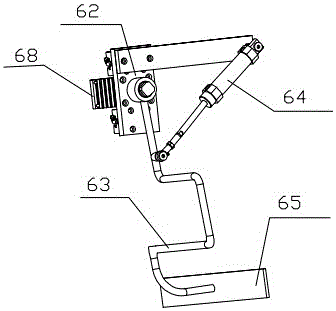

[0025] Depend on figure 1 to combine figure 2 , 3 , 4, 5, 6, 7, and 8, a bagging machine includes a frame 1, a feeding device 2, an air blowing device 3, a belt feeding device 4 for placing a packaging bag 7 and is used to pack An ironing tape device 5 for heat sealing the mouth of the bag 7, the feeding device 2 and the tape feeding device 4 are arranged in parallel, the ironing tape device 5 is arranged behind the tape feeding device 4, and the feeding device 2 It includes a conveyor belt 21 and a first driving member 22 that drives the conveyor belt 21 to move. The conveyor belt 21 is provided with a plurality of partitions 23, and a storage space for accommodating items to be packaged is formed between two adjacent partitions 23. Cavity 24, the blowing device 3 includes a blowing tube 31 for blowing open the packaging bag 7 and a limiting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com