Ink automatic bagging mechanism

An ink, automatic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as resource waste and environmental pollution, and achieve the effect of reducing investment costs, simplifying equipment structure, and reducing residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

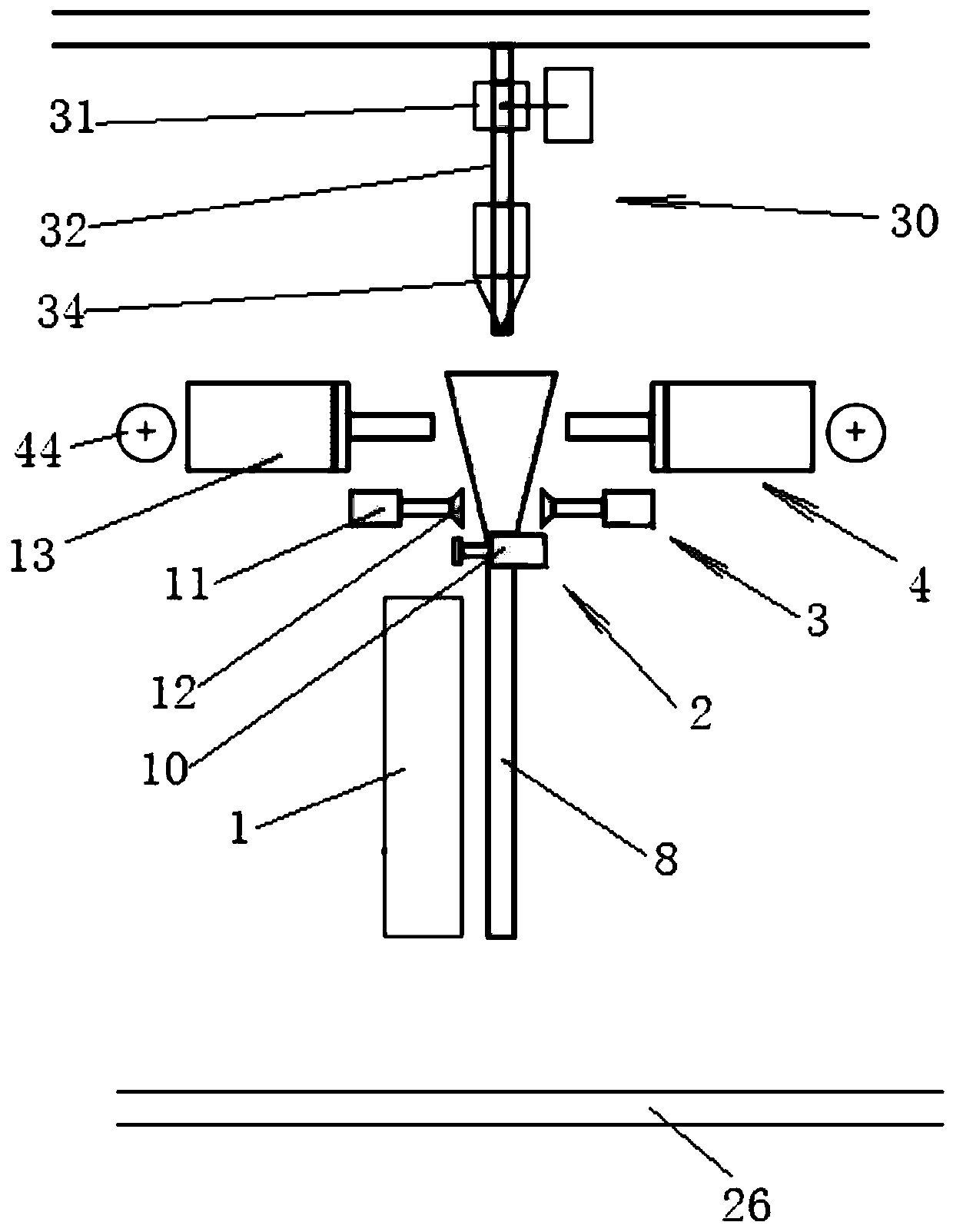

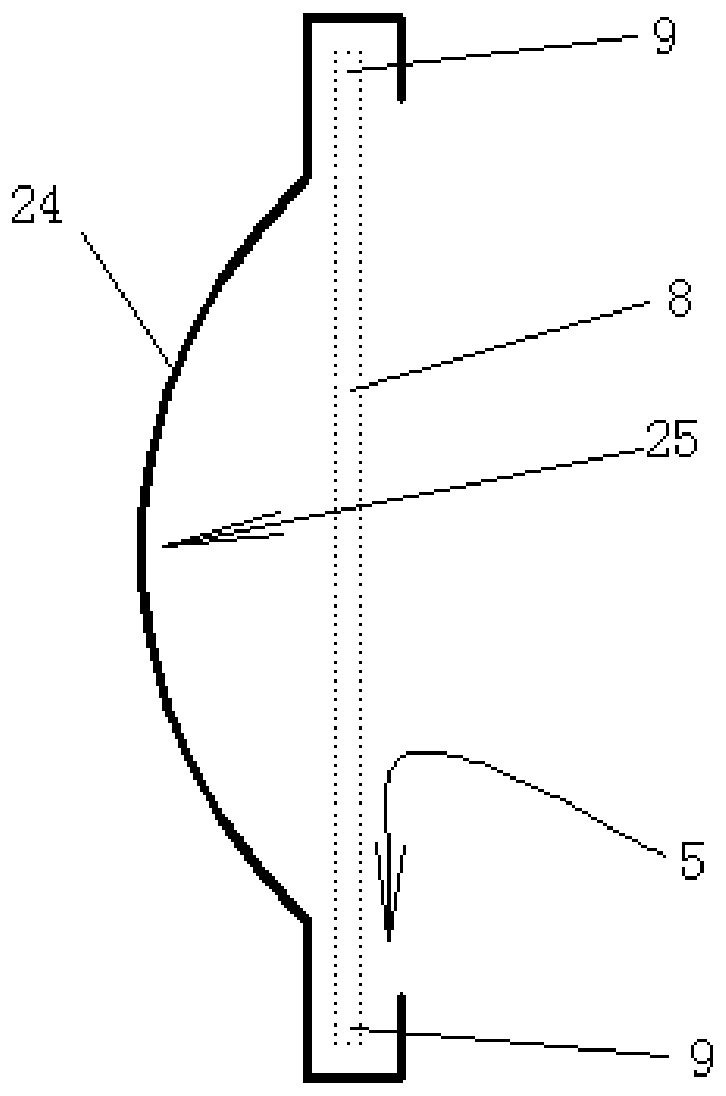

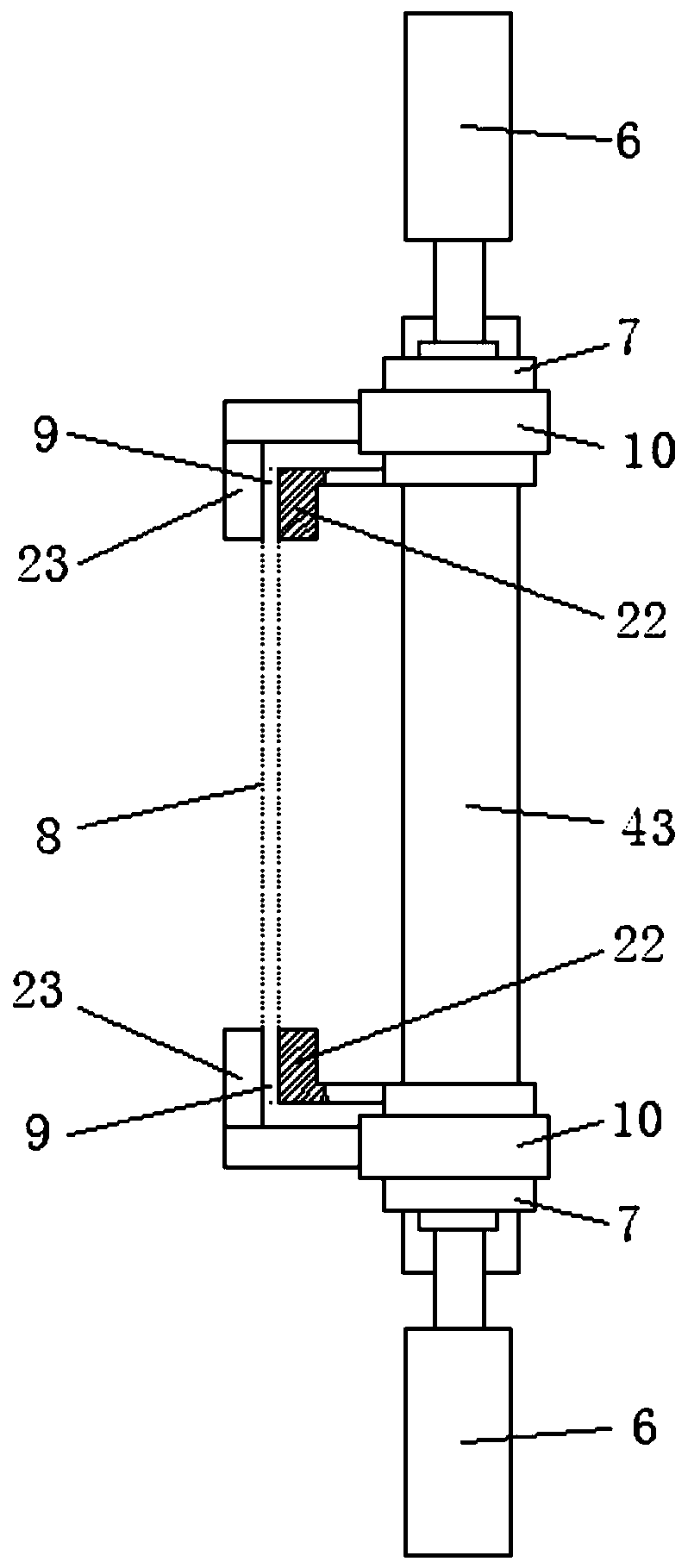

[0049] Such as Figures 1 to 8 Shown is an embodiment of an automatic ink bagging mechanism of the present invention, including a bag feeding guide seat 1, a bag clamping assembly 2, a bag opening assembly 3, a bag sealing assembly 4, and an ink filling and feeding device arranged in sequence from bottom to top 30; wherein, the bag feeding guide seat 1 is provided with a guide groove 5 for guiding the accurate placement of the bag 8, and the guide groove 5 is set upright; wherein, the bag clip assembly 2 includes a pair of pockets that are closed and closed A pair of movable bases 7 driven by the tight cylinder 6 to realize mutual approach and distance, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com