Coal mine underground grooving machine

A technology of slotting machine and coal mine, applied in cutting machinery, slitting machinery, propulsion, etc., can solve problems such as hidden safety hazards and low construction efficiency, and achieve the effects of improving efficiency, high operating efficiency, and increasing mechanization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

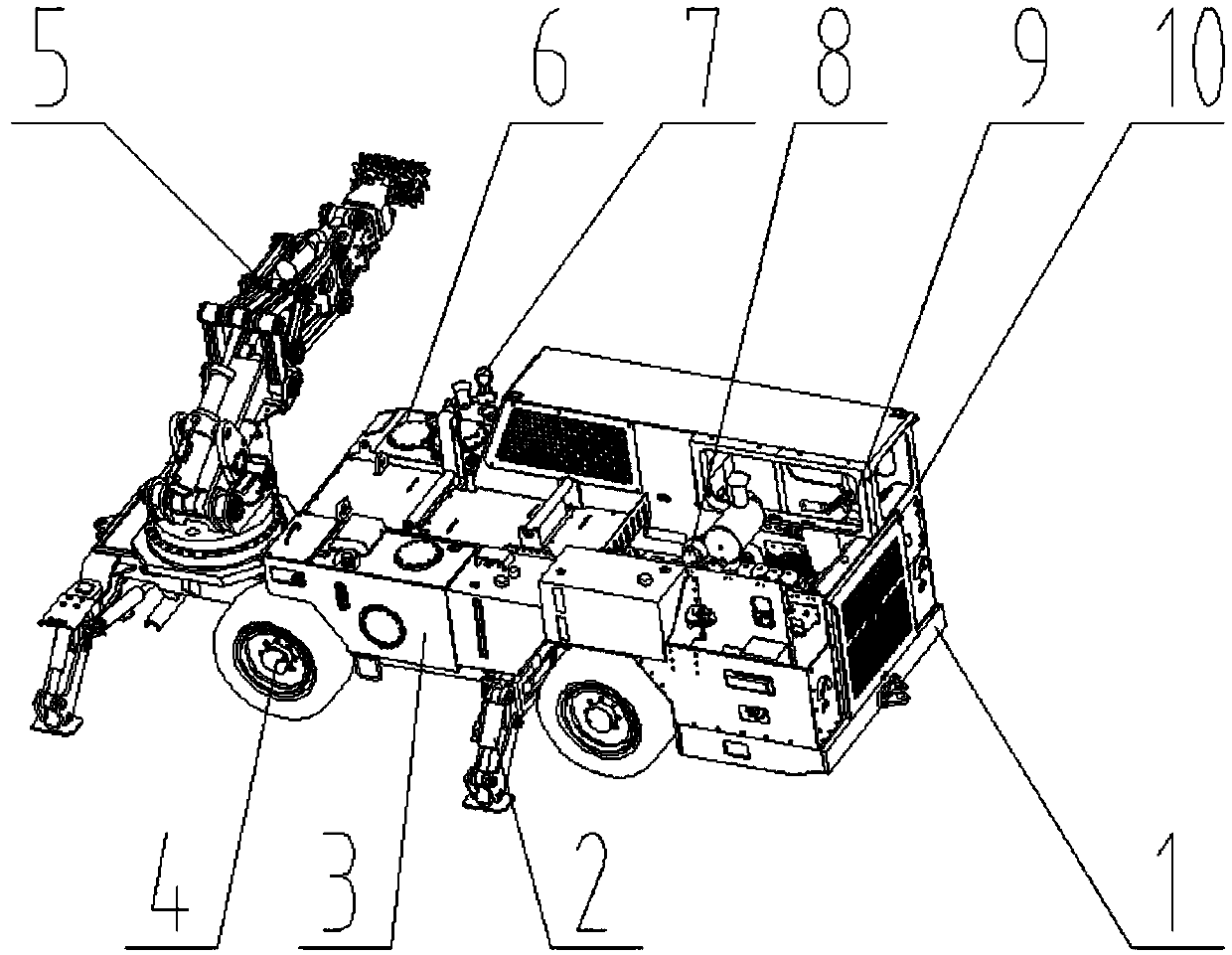

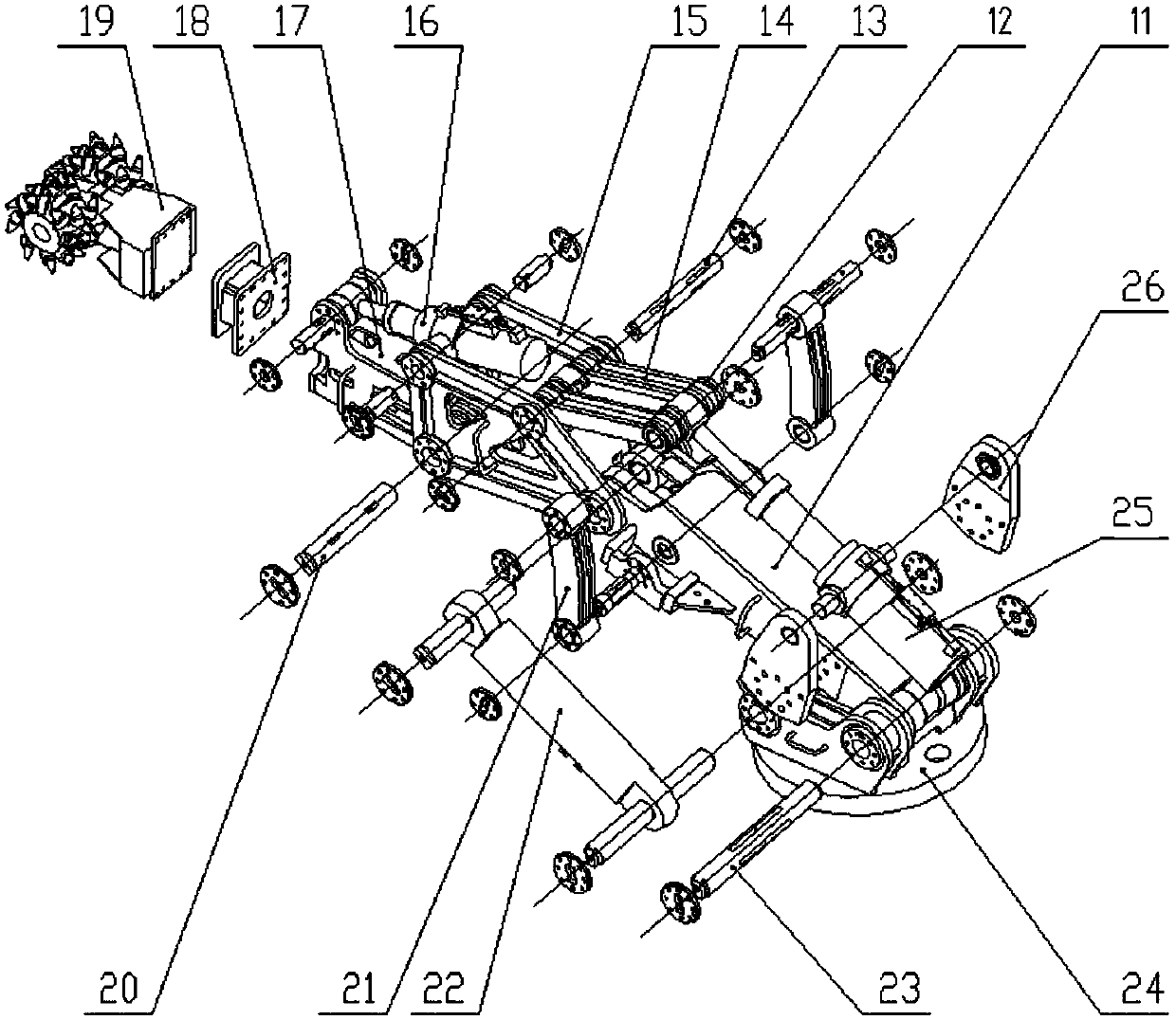

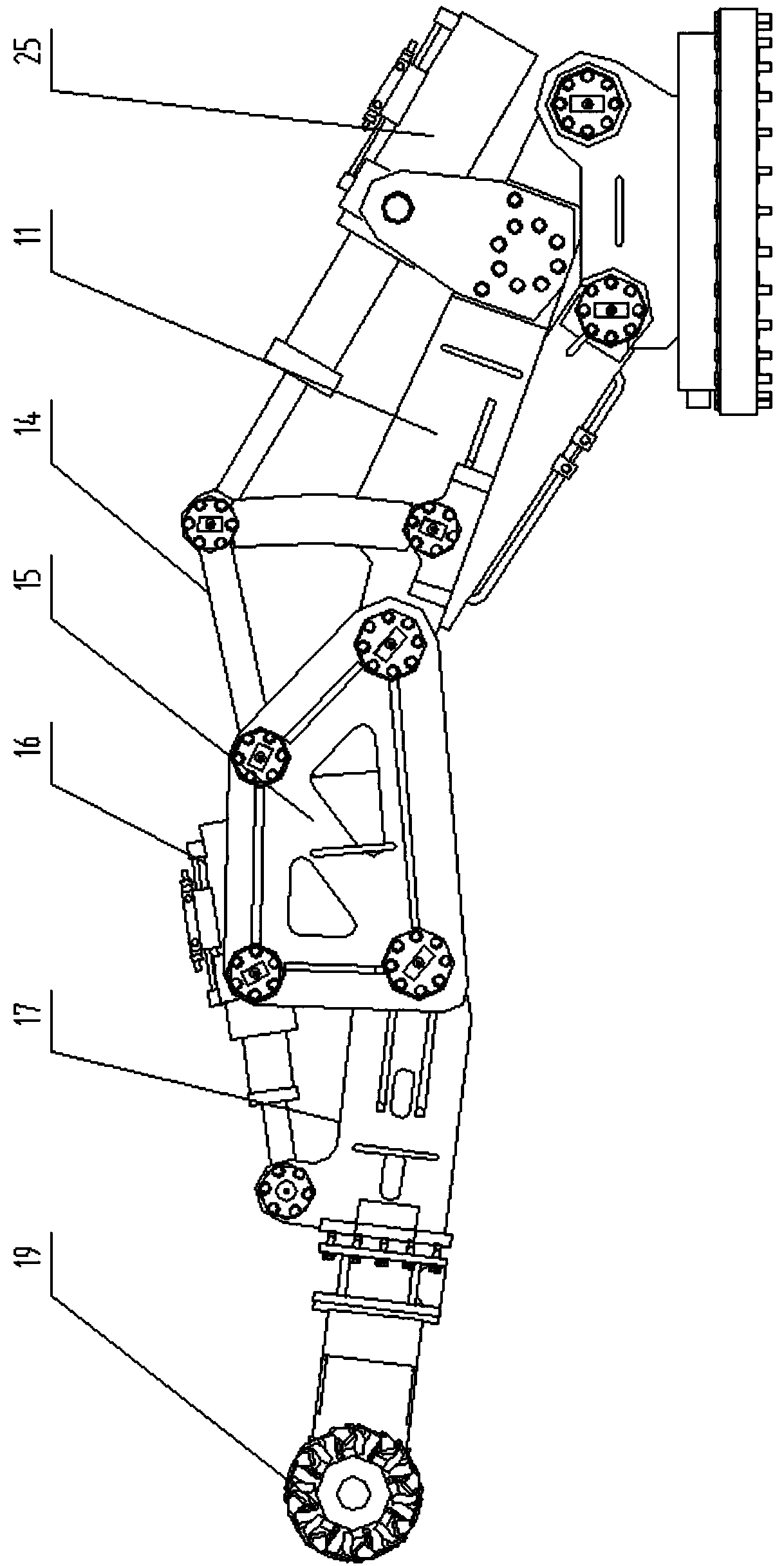

[0017] An underground slotting machine for coal mines, comprising a frame 1 on which a traveling mechanism 4, a hydraulic oil tank 3, a cab assembly 10, a hydraulic system, an electrical system 7, a pneumatic system 9, a dust removal system 6, and a power Device 8 and slotting device 5, said slotting device 5 is arranged on the rear end of vehicle frame 1, and slotting device 5 comprises cutting head 19 for slotting of underground roadway and base 24 installed on vehicle frame 1 through slewing bearing , the boom 11 is hinged on the base 24 through the hinge shaft I23 arranged horizontally, and the boom drive oil cylinder 22 for driving the boom to swing up and down is arranged between the boom 11 and the base 24; the front end of the boom is passed through the hinge shaft II is hinged with a middle arm 15, and the hinge axis II is set parallel to the hinge axis I; swing arms 21 are respectively installed on the left and right sides of the front part of the boom, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com