Full-automatic zinc slag removing machine

A clearing machine and fully automatic technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve problems such as low efficiency, heavy workload, and dangerous operations for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

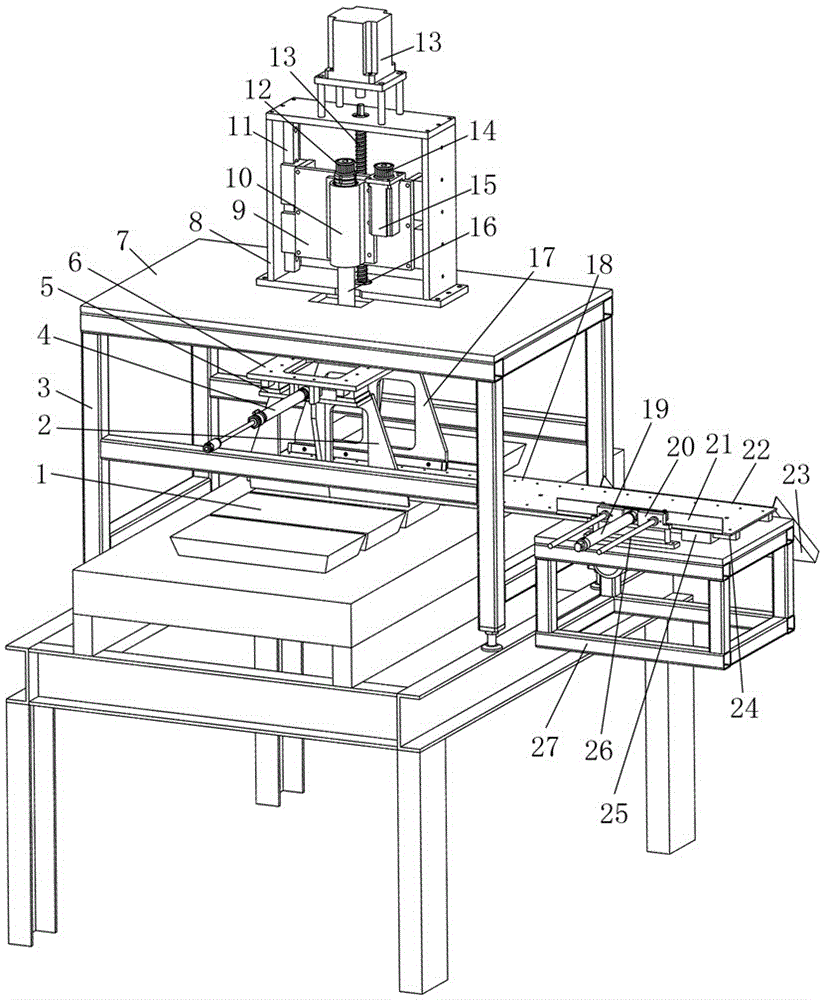

[0013] Such as figure 1 Shown, a kind of full-automatic zinc slag removing machine comprises frame 3, elevating mechanism, slag removing mechanism, unloading mechanism, and elevating mechanism is arranged on the top 7 of frame 3, and slag removing mechanism is arranged on elevating mechanism, and lower The feeding mechanism is arranged on one side of the frame 3. Lifting mechanism contains mechanism frame 8, vertical guide rail 11, lifting seat 9, motor 13, screw mandrel 13, screw mandrel nut, steering motor 15, main shaft 16, main shaft bearing block 10, and mechanism frame 8 is arranged on the top 7 of frame 3 superior. Vertical guide rail 11 is arranged on the inner both sides of mechanism frame 8, and lifting seat 9 is contained on the vertical guide rail 11, and screw nut is arranged on the lifting seat 9, and screw mandrel 13 wears on the screw mandrel nut, and the upper end of screw mandrel Form rotation connection with the top of mechanism frame 8, motor 13 links to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com