Method and device for automatic loading and unloading of bottle baskets for edible fungus production

An edible fungus and shelf device technology, applied in storage devices, transportation and packaging, etc., can solve the problems of low level of mechanization, high work intensity, and large labor costs, achieve improved level and efficiency, avoid operation hazards, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

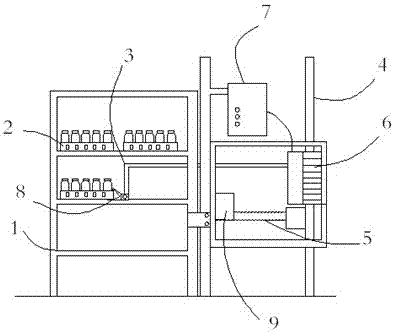

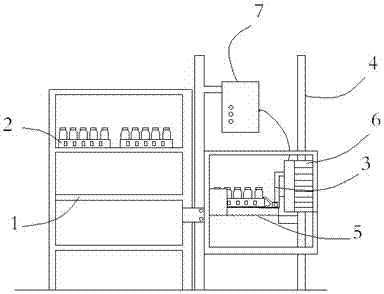

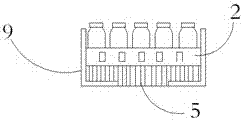

[0021] look first figure 1 and figure 2 , figure 1 and figure 2 It shows the working state of the bottle basket automatic transmission and the loading and unloading device of the present invention when it is off the shelf. It can be seen from the figure that the device of the present invention includes a bed frame 1 for storing bottle baskets 2, and the bed frame 1 is equipped with multiple Layered storage grids, bottle baskets 2 are neatly stacked in rows on the storage grids. In the present invention, a transmission frame 4 is arranged on the side of the bed frame 1, and a transmission device for transmitting the bottle basket 2 is arranged on the transmission frame 4. The transmission device includes a lifting conveyor belt 6 and a front and rear telescopic conveyor belt 5, and the lifting conveyor belt 6 is above the front and rear te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com