Transmission mechanism of fruitlet bagging machine

A technology of transmission mechanism and bagging machine, which is applied to plant protective covers, botany equipment and methods, gardening, etc., can solve the problems of low degree of automation, slow bagging, and low efficiency, so as to improve bagging efficiency and reduce bagging efficiency. Bag Effort and Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

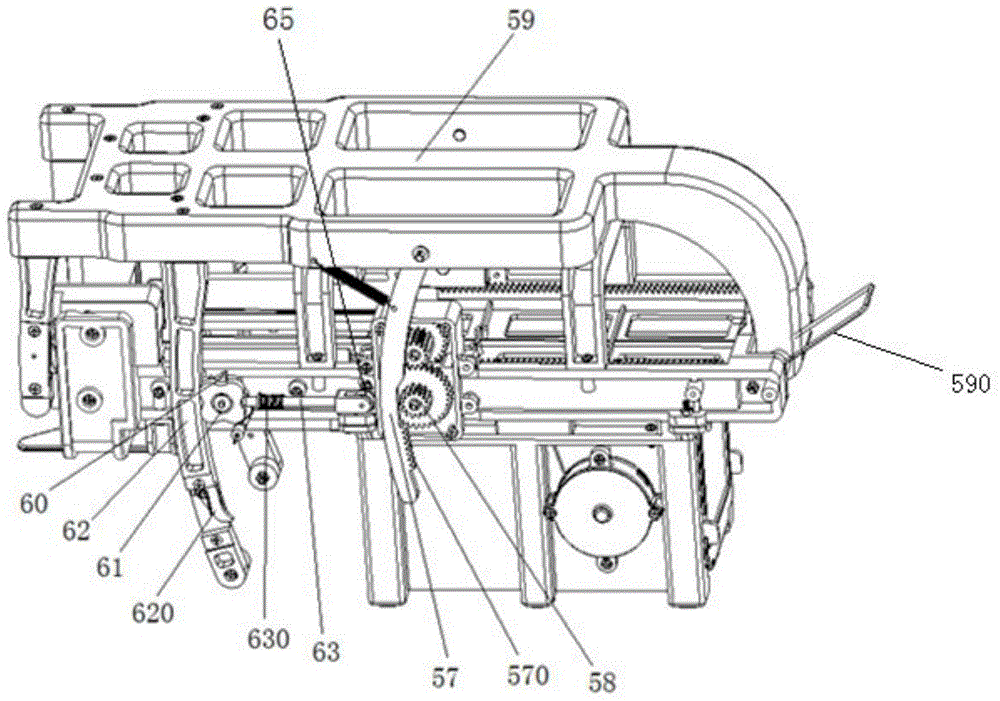

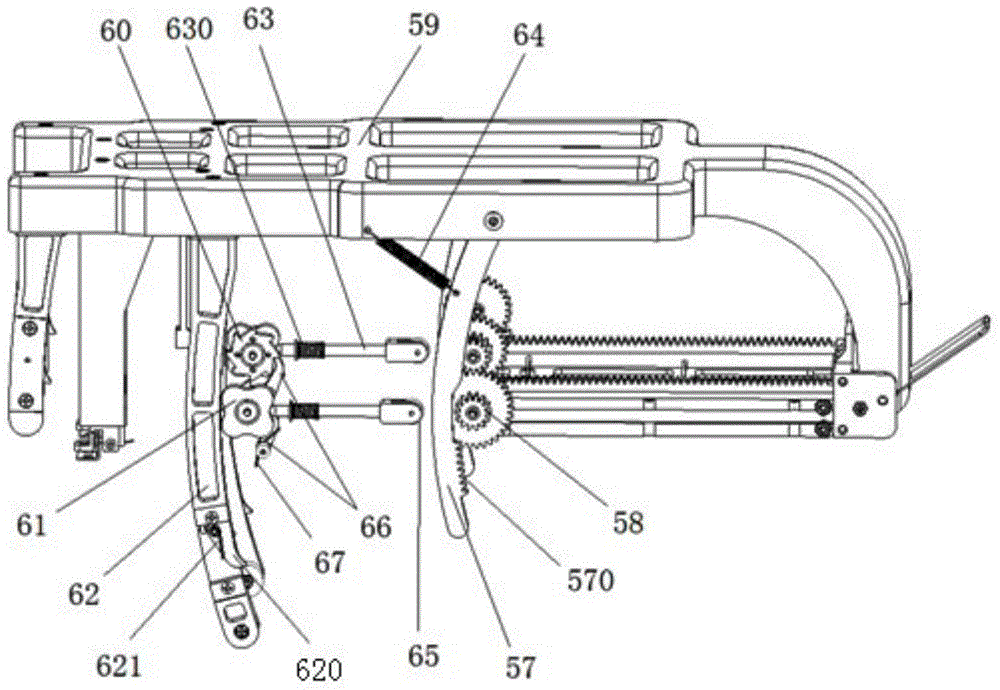

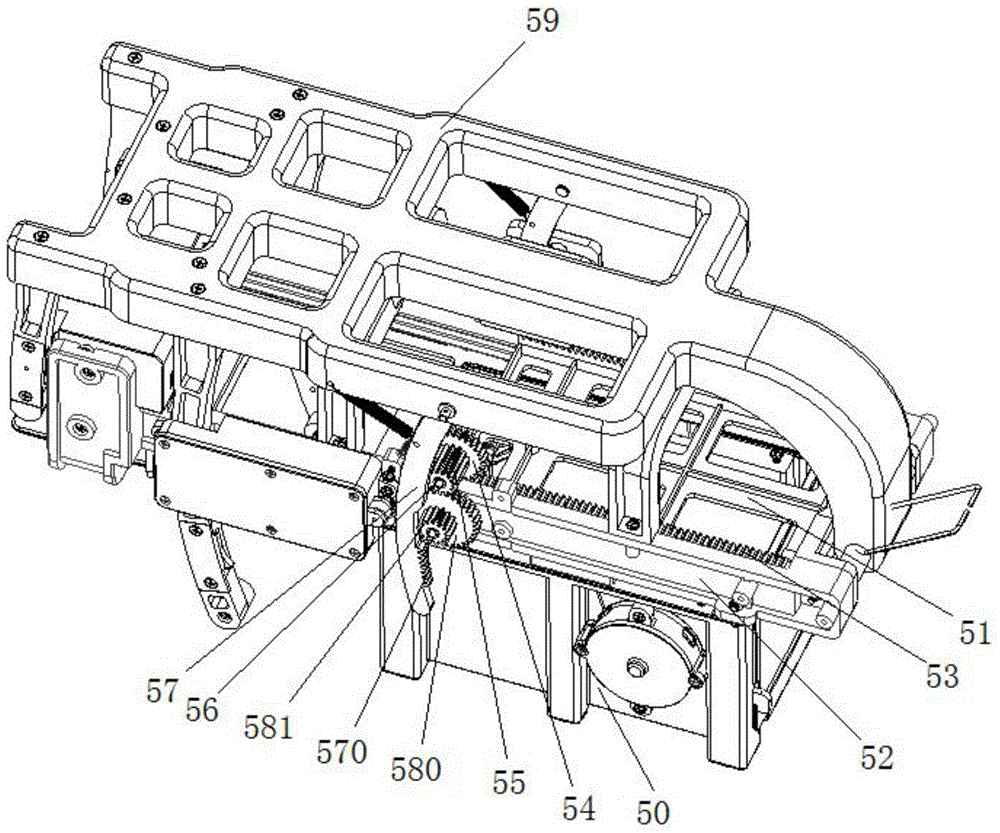

[0033] see Figure 1-7, a young fruit bagging machine transmission mechanism, which includes an upper arm 59 whose end is hinged on the bagging machine, the hinge shaft of the upper arm 59 is provided with a device that drives the upper arm 59 away from the upper side of the bagging machine Rotating second torsion spring 590, on the upper arm 59 from the hinge shaft to the end of the upper arm 59, the push arm 57 for driving the bag feeding mechanism and the intermittent push rod 62 for driving the intermittent mechanism to rotate are arranged in sequence, The intermittent mechanism is used to switch the actions of the bag feeding mechanism and the bag opening device. The bag opening device includes an adsorption pull rod 40 and a collision mechanism. A magnet 401 is arranged below the adsorption pull rod 40. The magnet 401 absorbs the iron wire 403 arranged on the front of the bag 402 to make the folded sleeve The front and back of the bag 402 approach or separate, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com