Self-floating type clamp iron for limiting core assembly pouring device

A self-floating, core-forming technology, applied in cores, mold boxes, casting and molding equipment, etc., can solve problems such as affecting production efficiency, many consumables, and tedious operations, so as to speed up production beats, reduce operating procedures, and avoid swelling. box effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

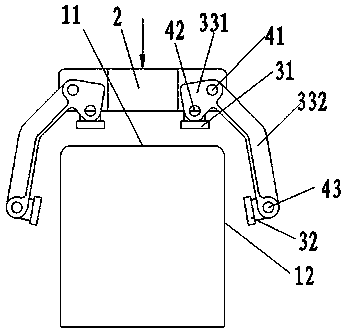

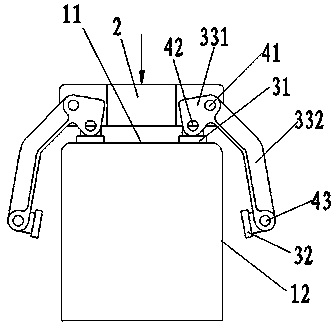

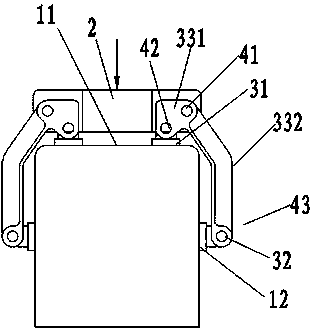

[0019] Embodiment one: see Figure 1-Figure 5 , as shown in the legend therein, a self-floating weight used for the limit core group pouring device is used to simultaneously compress the upper mold 11 of the core group and the side mold 12 of the clamped core group, including a weight Body 2 and a self-floating clamping mechanism, which includes four clamping devices symmetrically arranged front, rear, left and right, each clamping device includes an upper pressing block 31, a side pressing block 32 and a clamping lever, the clamping lever is hingedly connected to the weight body 2 through the first rotating shaft 41 and rotates in the vertical plane with the first rotating shaft 41 as a fulcrum, and one end of the clamping lever extends to the weighting body 2 The bottom of the clamping lever (between the weight body 2 and the upper type 11) forms the first lever arm 331, and the other end of the clamping lever extends to the bottom of the first lever arm 331 (outside the sid...

Embodiment 2

[0023] Embodiment 2: The rest is the same as that of Embodiment 1, the difference is that an easy-to-rotate bearing is provided between the above-mentioned clamping lever and the first rotating shaft, and a bearing is also provided between the above-mentioned first lever arm and the second rotating shaft. With the bearing that is easy to rotate, the above-mentioned second lever arm is directly fixedly connected with the side pressure block, and the adjustment of the side pressure block cannot be realized without being connected through the above-mentioned third rotating shaft.

Embodiment 3

[0024] Embodiment 3: The rest is the same as that of Embodiment 1, the difference is that the above-mentioned clamping lever can use one or more combinations of connecting rod structure or wedging structure to realize the self-weight of the weight body It is converted into side clamping force, which is a prior art, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com