Automatic liner bottom plate forming production line

An automatic forming and production line technology, applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve the problems that the production line cannot meet the production demand, the product quality is unstable, the deviation of the sheet metal, etc. The effect of inaccurate positioning, reduced free flow space, and fast conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with more specific embodiments, but it should be pointed out that the liner bottom plate automatic forming production line of the present invention is not limited to this specific structure. Those skilled in the art can obviously understand that the following explanations can be directly applied to other similar structures not specified here even without any adjustment or modification.

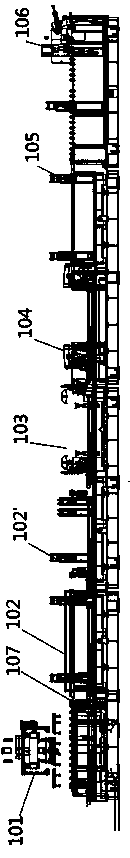

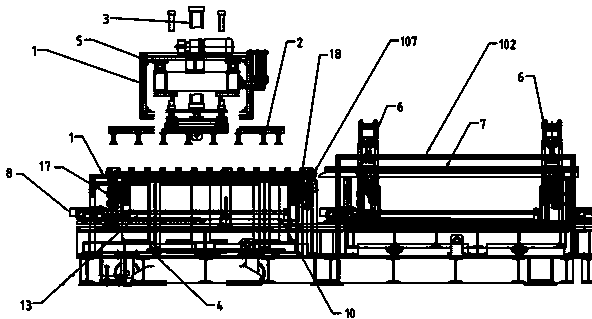

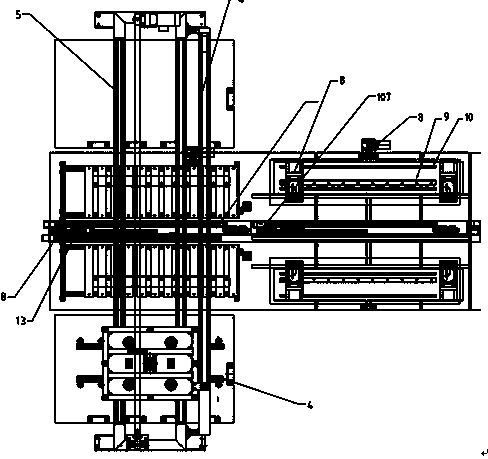

[0030] Such as figure 1 As shown, the material pieces of the liner bottom plate automatic forming production line of the present invention run from left to right, and the production line includes an electric control cabinet (not shown in the figure), five-connected servo conveying manipulator 107 and automatic upper Material machine 101, punching machine 102, punching machine 102', long-side bending machine 103, short-side bending machine 104, four-corner forming machine 105 and Z-shaped bending machine 106 stations, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com