Semitrailer integral axle tube extrusion moulding equipment and method

An extrusion forming and equipment technology, which is applied in metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problems of small bearing capacity and weak fatigue resistance, and achieve improved bearing capacity and low production cost. , the effect of speeding up the production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

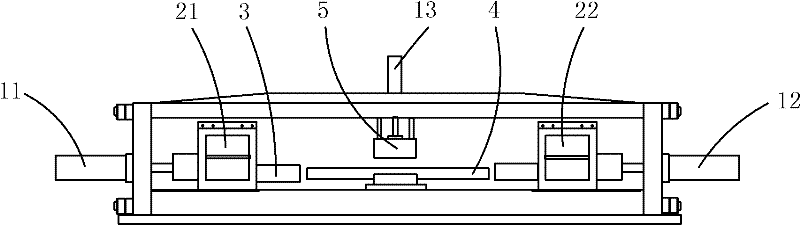

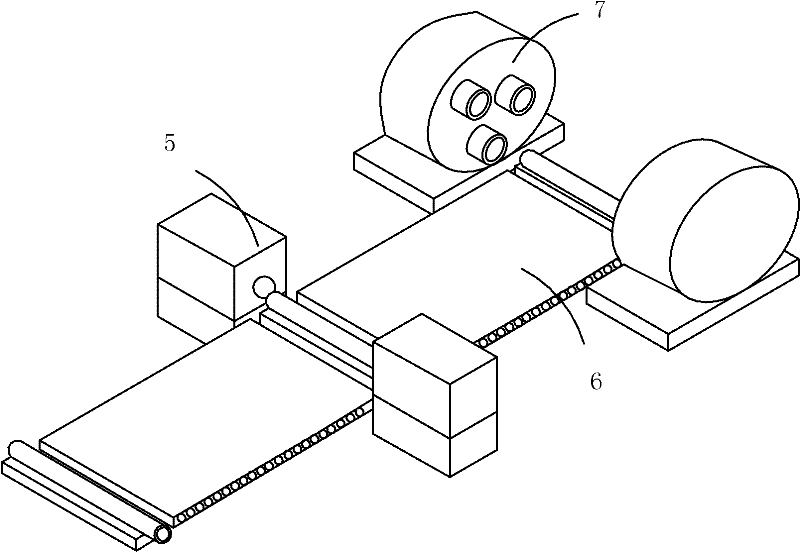

[0030] The parts represented by each label in the accompanying drawings are as follows:

[0031] The first cylinder 11 The second cylinder 12 The third cylinder 13 The first slide 21

[0032] Second sliding seat 22 Die change wheel 3 Shaft tube 4 Clamp block 5

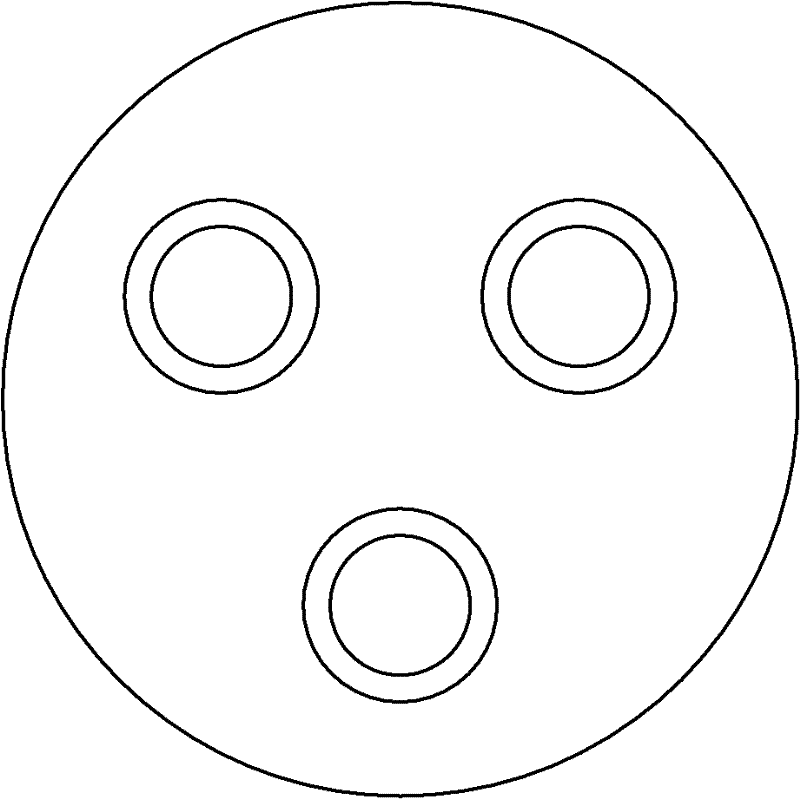

[0033] Stepping and traversing device 6 Intermediate frequency heating furnace 7

[0034] A semi-trailer axle tube extrusion forming equipment is composed of a hydraulic press, an intermediate frequency heating furnace, a first sliding seat, a second sliding seat, and a clamping device for the axle tube, which realizes continuous processing on the same production line and improves production efficiency. The entire production process is controlled by a PLC program, which effectively controls the input and output of the production process, heating temperature control and other i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com