High strength and high toughness as-cast-condition QT800-5 nodular cast iron and production method thereof

A ductile iron, high-toughness technology, applied in the field of metal casting and metal materials, can solve the problem of not being able to meet industrialized mass production, etc., and achieve the effects of long production cycle, wide application range and strong thermal insulation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Ordinary clay green sand is filled into the sand box and molded on a micro-seismic compaction molding machine. The average hardness of the sand mold is controlled at about 82. The raw material is Q12 pig iron, and its composition is (mass fraction, the same below): C 3.60%~3.90%, Si 2.30%~2.8%, Mn<0.30%, P<0.04%, S≤0.02%, Cu 0.50%~1.20 %, Mo<0.30%, Sb<0.02%, and the balance is iron. The induction furnace is used for smelting, and the ingredients are analyzed and adjusted during the process to make the ingredients qualified. Finally, the temperature is raised to 1520°C and left for 5-8 minutes to remove the slag and come out of the furnace. Add 1.3% FeSiMg8Re5 spheroidizer, 0.65% 75 ferrosilicon, 0.42% 60 molybdenum and 0.8% pure copper rods in the nodulizing bag in turn, and cover each layer with perlite after compacting, and then put the iron in the furnace The liquid is washed into the spheroidizing bag, and after slag making and slag removal, the bag-inoculation tre...

Embodiment 2

[0027] The other steps and parameters of this embodiment are exactly the same as in Example 1, except that the Sb in the subcontracting inoculant is replaced by Sn, and Sn<0.03%; the amount of nodulizer added is changed: 1.4% FeSiMg8Re5 nodulizer, 0.76% 75 ferrosilicon, 0.42% 60 molybdenum iron and 0.7% pure copper rod.

[0028] The technical indicators of the cast Y-type test block produced in this example are: spheroidization grade 2, graphite size 6-7, pearlite content 65-70%; mechanical properties: tensile strength Rm814-816MPa, elongation A5 .6 ~ 6.8%.

Embodiment 3

[0030] The other steps and parameters of this embodiment are exactly the same as those in Example 1, except that: the Sb in the subcontracting inoculant is replaced by Sn, and Sn<0.03%; the addition of nodulizing agent is changed: 1.5% FeSiMg8Re5 spheroidizer, 0.95% 75 ferrosilicon, 0.42% 60 molybdenum iron, 1% pure copper rod and 1% Ni.

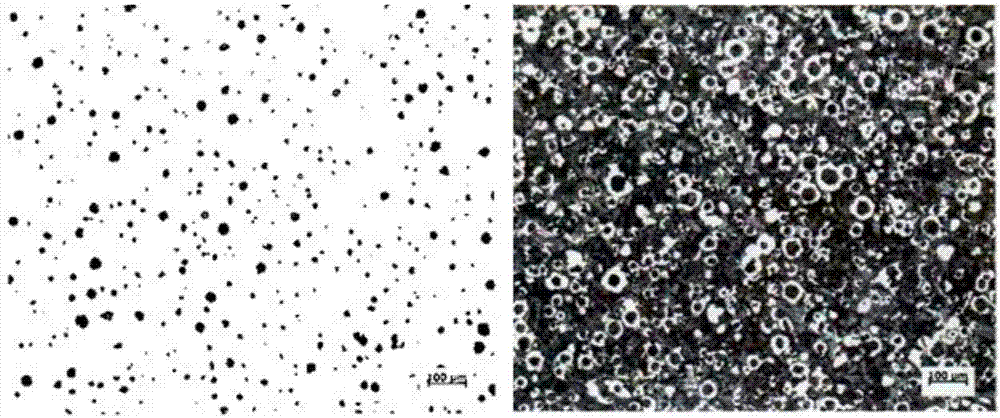

[0031] The technical indicators of the cast Y-type test block produced in this embodiment are: spheroidization grade 2, graphite size 6-7 (see attached figure 1 Right), the pearlite content is 65-70% (see attached figure 1 Left); mechanical properties: tensile strength Rm 809~829MPa, elongation A5.4~7.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com