Press-robot synchronous movement coordination method

A technology of synchronous movement and coordination method, applied in the field of automation, can solve the problems affecting the production beat of the whole line and long cycle period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

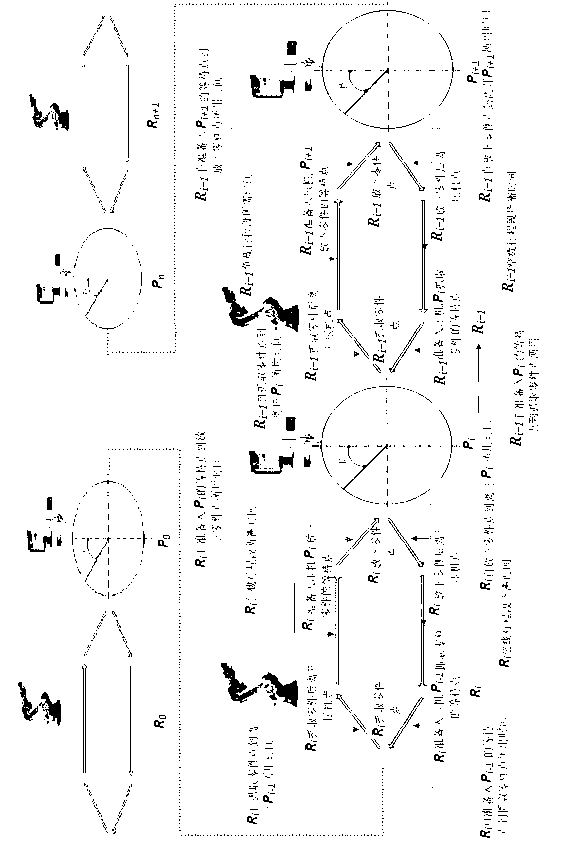

[0037] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 The principle of the basic logic flow diagram for press-robot synchronization is explained: in the current robotic stamping automation line, the speed of the press usually does not change, the press is too slow to keep up with the speed of the robot, and the flexibility of the robot's movement speed adjustment Very large, so the press line uses synchronous motion control technology to adjust the robot speed to reduce the waiting time.

[0038] In a press cell, with robot R i Arrive at press P i The moment when the part is put down is taken as the starting point, and the press P is calculated i start moment. Robot R i Run until the parts are put down and leave the press, press P i start; calculate P i Run to beta angle clock time T (i.e. allow R i+1 Enter the press P i moment); the simultaneous computation allows the robot R i Ready again for press P i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com