Automobile engine compartment welding production line

A welding production line and automobile technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor flexibility, increased investment cost, and inability to meet high-tempo production requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

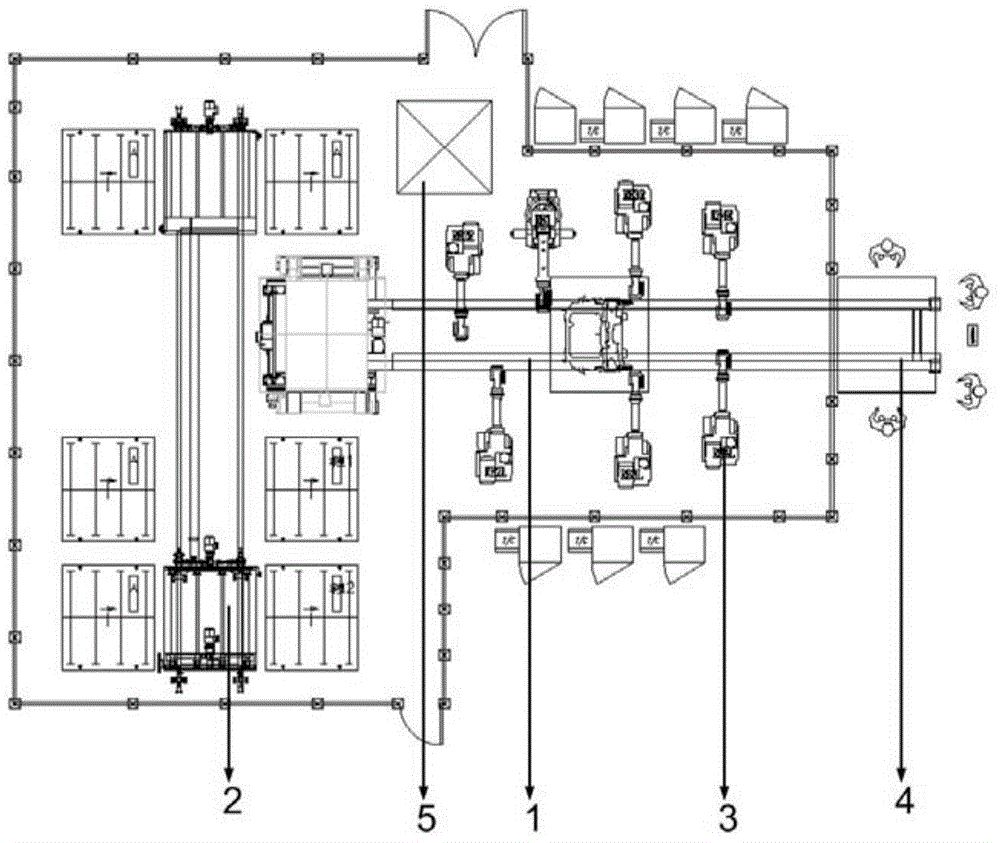

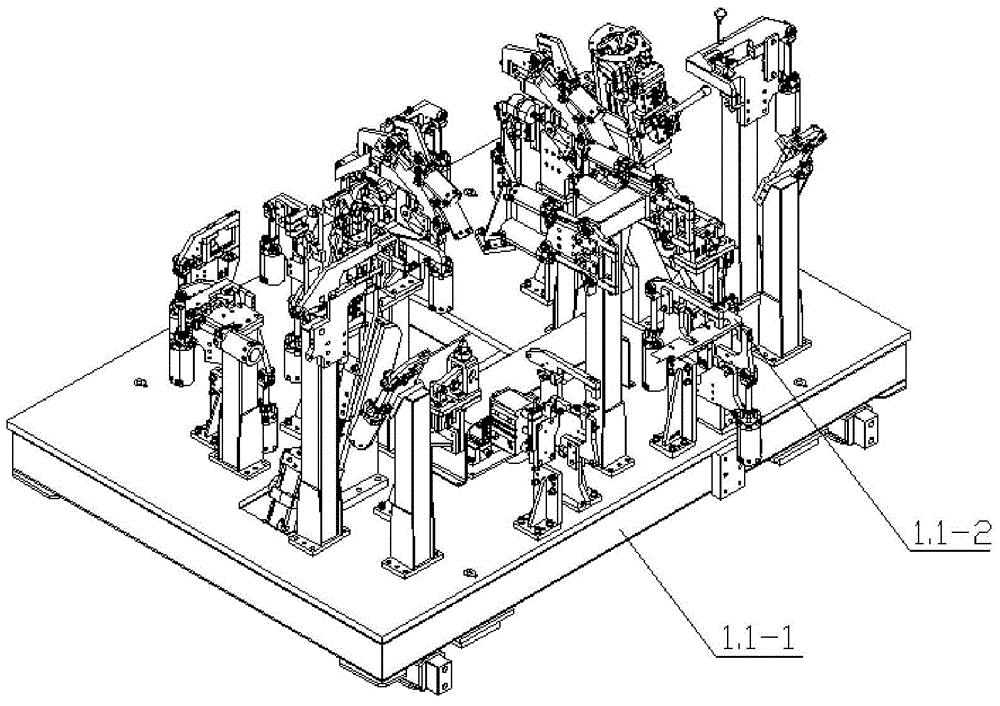

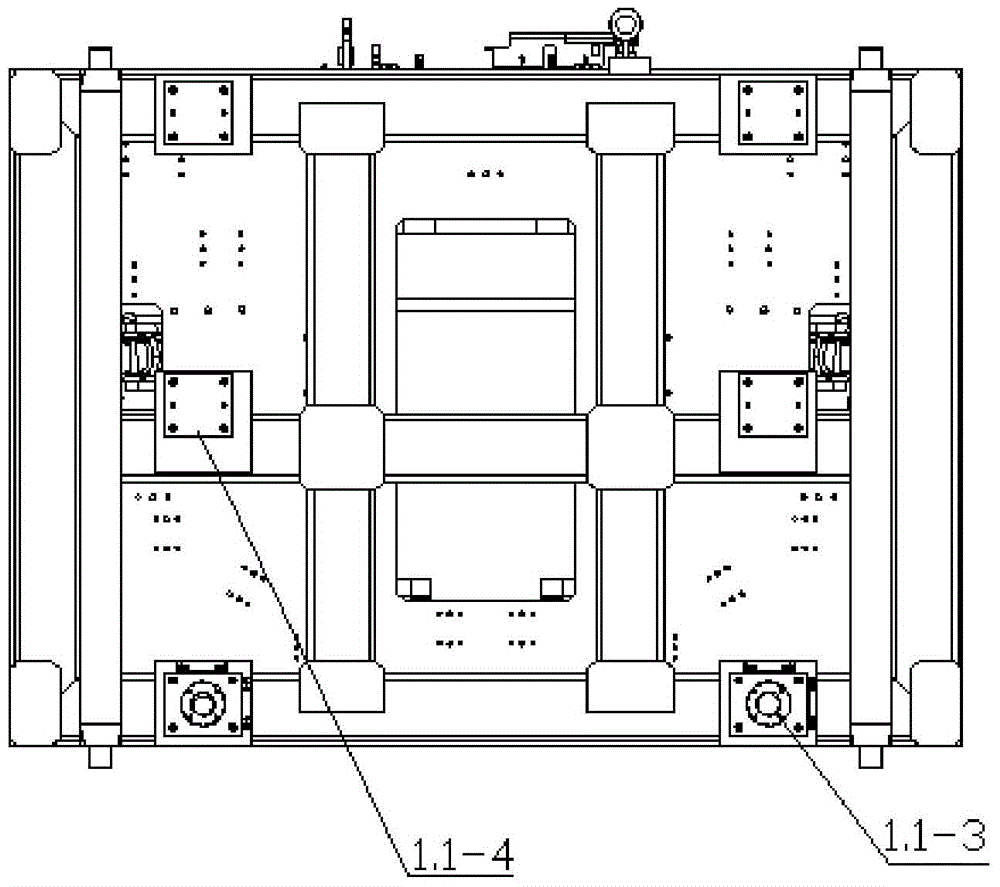

[0037] Such as Figure 1~3 As shown, the automobile hair cabin welding production line provided by the present invention includes an accompanying fixture system 1, a fixture switching area 2, a welding area 3, an upper part area 4, and a workpiece storage and conveying area 5. The accompanying fixture system 1 includes a clamp body 1.1, The clamp body 1.1 is detachably fixed on the sliding base 1.2 to facilitate the switching of clamps of different shapes. The sliding base 1.2 can slide on the track device 1.3, and the track device 1.3 guides the clamp The switching area 2, the welding area 3 and the upper part area 4 are communicated in pairs, so that the pallet system 1 can move to the station positions corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com