Processing method for rolling casting device

A processing method and a technology of processing steps, which are applied in the field of sand casting, can solve problems such as poor feeding rate of molten steel, temperature difference, easy occurrence of shrinkage porosity, shrinkage cavity, etc., and achieve reduced pouring deformation, fast feeding rate, and reduced box closing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

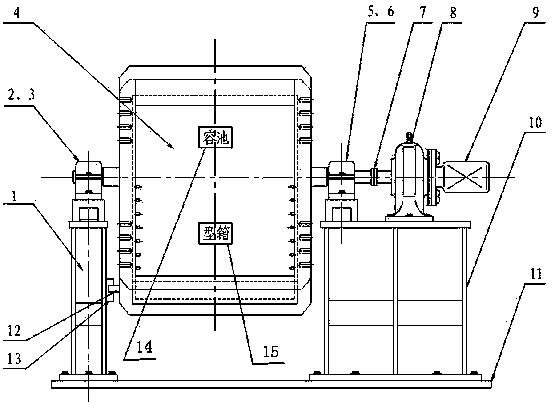

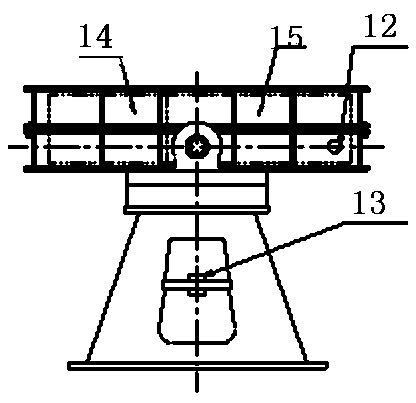

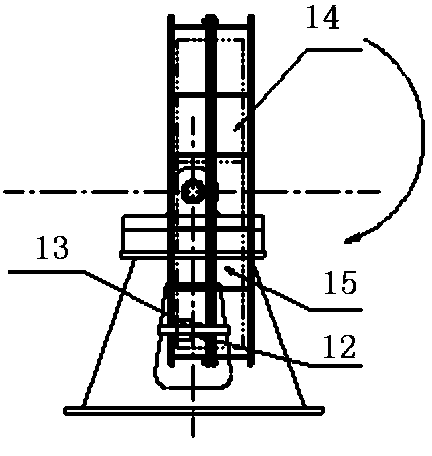

[0036] Below in conjunction with accompanying drawing, the present invention will be further described;

[0037] A processing method for a tumbling casting device, characterized in that: the processing steps are as follows;

[0038] (1) Shape:

[0039] 1). Prepare cold iron, positioning pin, insulation riser, core bone, sand box and paint;

[0040] 2). Check and confirm the mold, clean the surface of the mold and apply a release agent;

[0041] 3). Modeling on the upper box, adjust the sand box and put it away, place the hanging sand bars and start modeling,

[0042] Make several sand-filled holes at the head of the mud core, and then fill the sand to cover the mold; pay attention to using a sand pound to pound the sand tightly. After the molding sand is solidified, tap the mold to complete demoulding.

[0043] 4) The lower box is shaped, and the sprue is arranged according to the process requirements. All the joints of the porcelain tubes should be wrapped and glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com