IC punching formation equipment

A technology of forming equipment and integrated circuits, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of difficult to increase the overall speed of the system, long response time of cylinder action, low stability and reliability, etc. Reduced response time, short cycle times, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

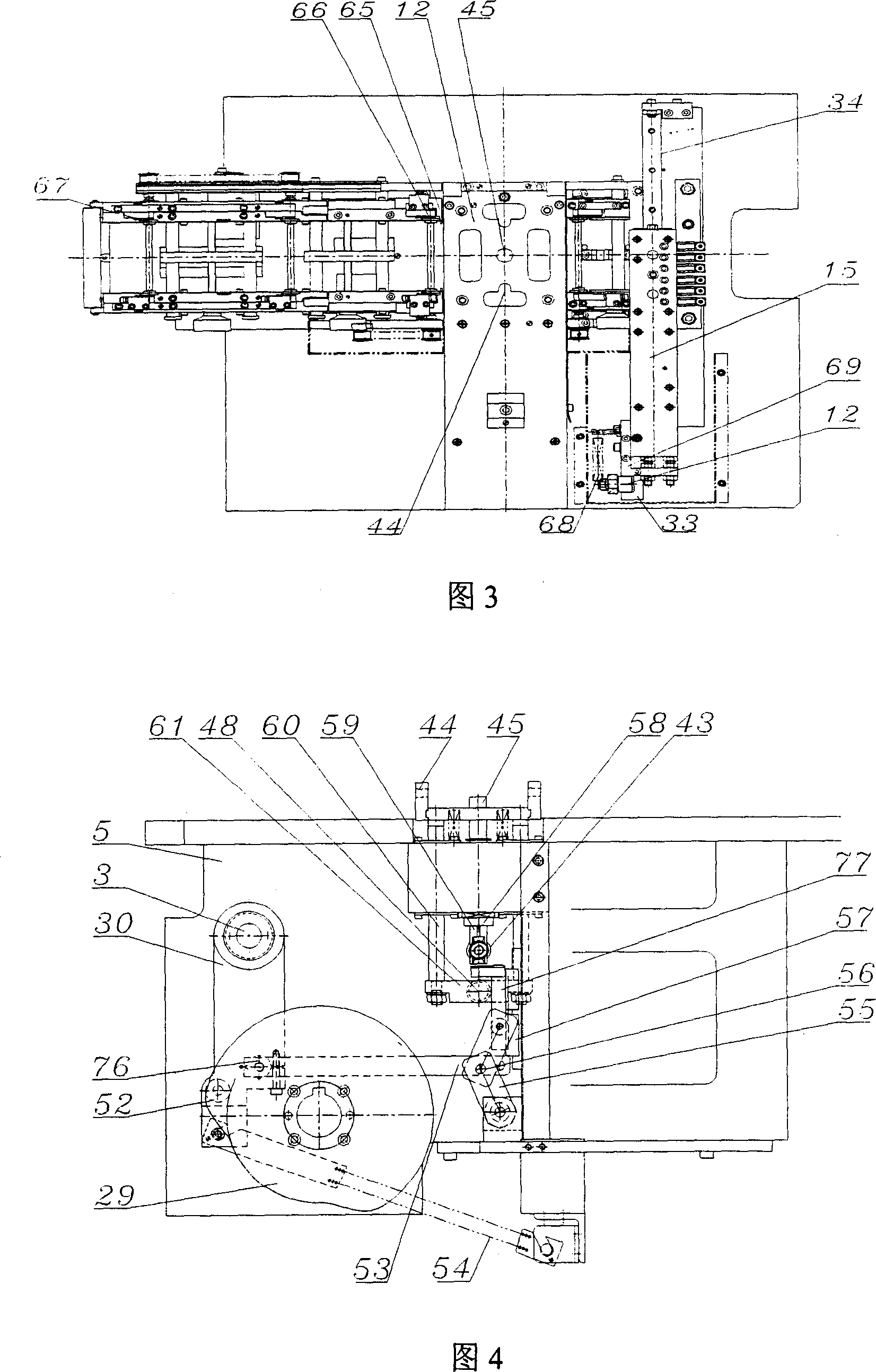

[0027] The invention includes a driving device, a feeding device, a separating device and a discharging device.

[0028] The drive device, as shown in FIG. 2 , includes a drive wheel 1 and a camshaft 2 connected to a frame 5 . The camshaft 2 is connected on the frame 5 by bearings 23 at both ends, and the transmission wheel 1 is fixedly connected to one end of the camshaft 2, and the transmission wheel 1 and the power source are connected by a synchronous belt 31 to realize transmission.

[0029] The feeding device is shown in Figure 2, which includes a feeding motor 6, a feeding roller 8, a pressing roller 67 and a pressing cylinder 7, and the pressing roller 67 and the feeding roller 8 are pressed against the lead frame under the action of the pressing cylinder 7. The feeding is driven by the feeding motor 6; the feeding detection device is composed of a detection sensor 10, a brake cylinder 11 and a brake block 65, and the detection sensor 10 is fixed on the detection plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com