Adjustable press machine

A press and adjustable technology, applied in the field of presses, can solve the problems of poor versatility, inability to adjust metal parts, small application range, etc., and achieve the effects of easy operation, improved application range, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

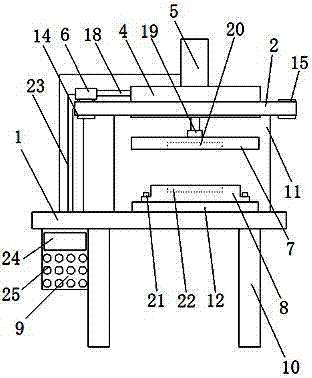

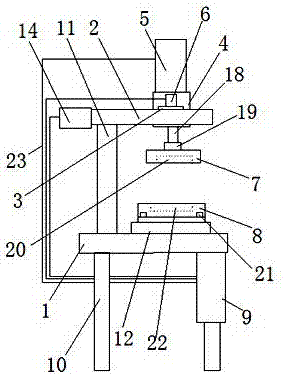

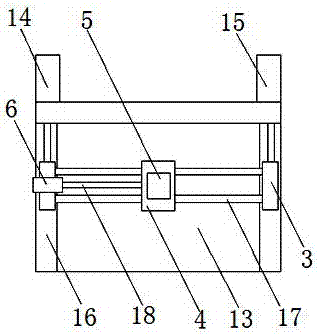

[0018] as attached Figure 1-3 As shown, an adjustable press includes an operating table 1, an adjustment frame 2, a slider 3, a fixed block 4, a cylinder one 5, a cylinder two 6, a stamping plate 7, a lower backing plate 8 and a control box 9. It is characterized in that: the operating table 1 is arranged on the bracket 10, and a fixing plate 11 and a positioning plate 12 are arranged on the operating table 1, and the adjusting frame 2 is arranged on the fixing plate 11, and is arranged on the adjusting frame 2 In the adjustment chamber 13, the third cylinder 14, the cylinder four 15, and on the two sides of the adjustment frame 2 opposite to the adjustment chamber 13 are arranged on the slideway 16, the cylinder three 14, the cylinder four 15 are respectively provided with adjustment rods 18, Connect the adjusting rods 18 on the third cylinder 14 and the cylinder four 15 to the slider 3 respectively, the slider 3 is arranged on the slideway 16, and a connecting rod is arrang...

Embodiment 2

[0020] as attached Figure 4 As shown, an adjustable press includes an operating table 1, an adjustment frame 2, a slider 3, a fixed block 4, a cylinder 1 5, a cylinder 2 6, a stamping plate 7, a lower backing plate 8, a control box 9 and a walking The wheel 27 is characterized in that: the operating table 1 is arranged on the bracket 10, and a fixing plate 11 and a positioning plate 12 are arranged on the operating table 1, and the adjusting frame 2 is arranged on the fixing plate 11. The frame 2 is arranged on the adjusting chamber 13, the third cylinder 14, and the fourth cylinder 15, and is arranged on the slideway 16 on the opposite sides of the adjusting frame 2 of the adjusting chamber 13. The three cylinders 14 and the fourth cylinder 15 are respectively provided with Adjust the rod 18, and connect the adjustment rods 18 on the cylinder three 14 and the cylinder four 15 to the slider 3 respectively. The slider 3 is arranged on the slideway 16 and between the slider 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com