Automatic lubricating device for stamping die

A technology of automatic lubrication and stamping die, applied in the field of stamping die, can solve the problems of complicated operation, affecting the service life of stamping die, dissolution and accumulation of oil film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

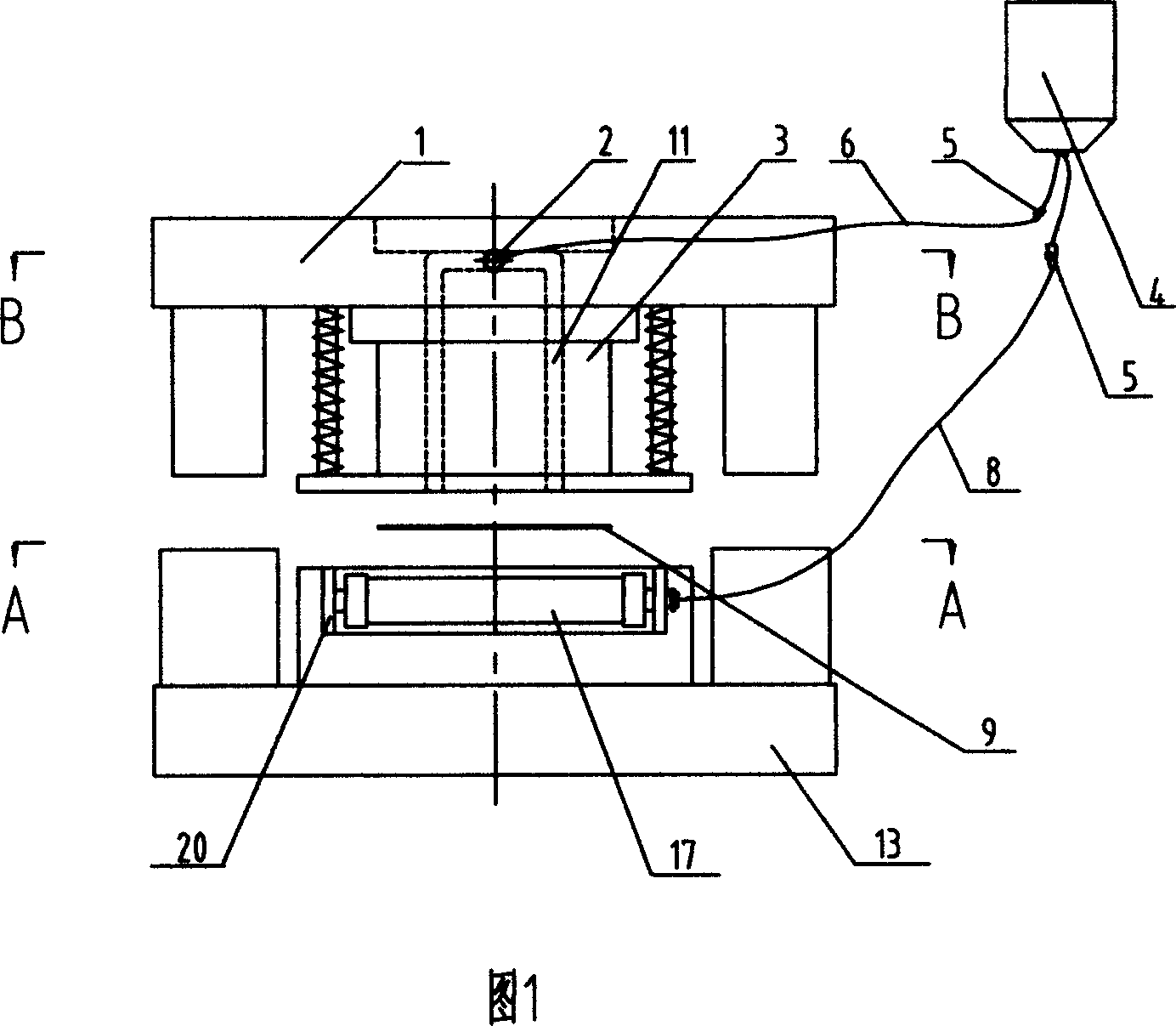

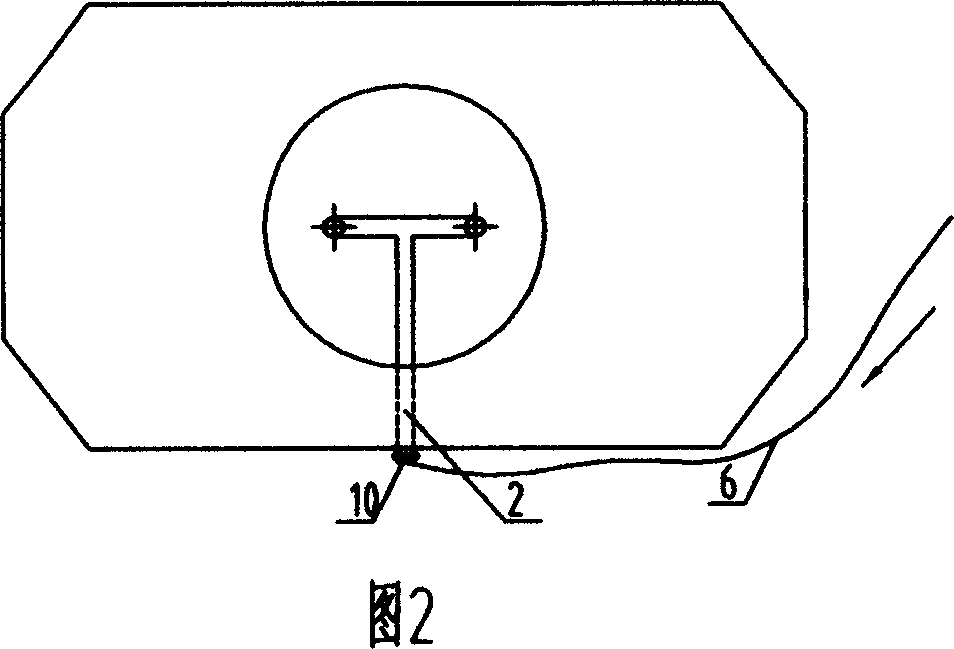

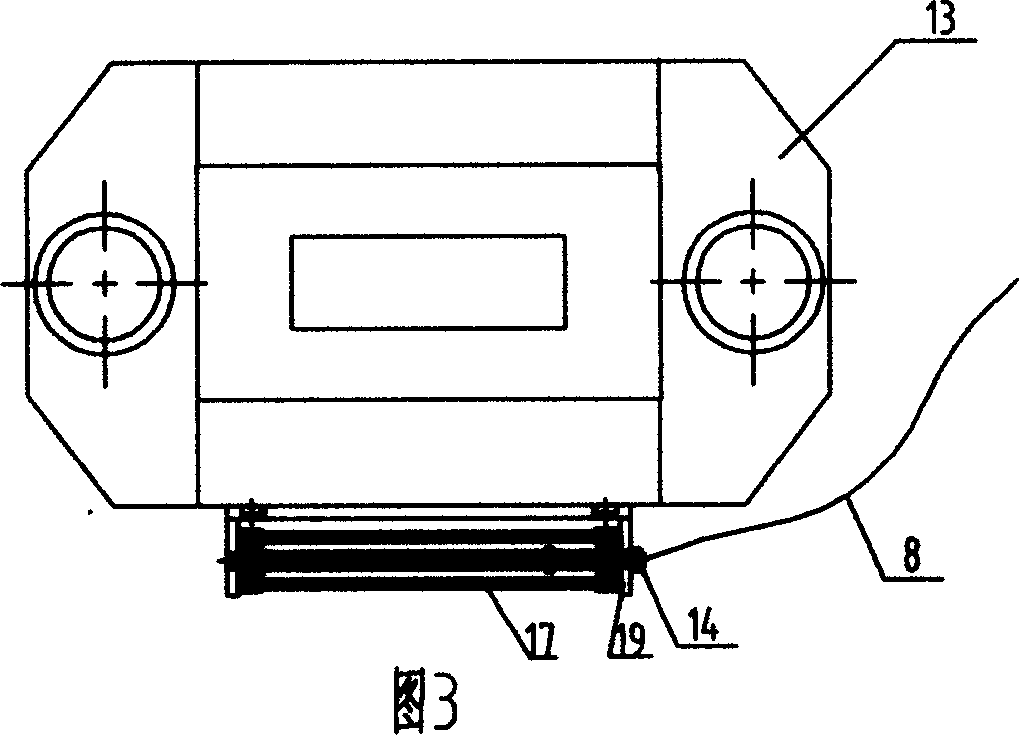

[0017] Referring to Fig. 1 and Fig. 2, the upper and lower dies of the automatic lubricating device of the stamping die are fixedly connected with the upper and lower die bases respectively by bolts, and the upper die 3 is provided with at least two or more holes passing through the upper and lower ends. Through holes 11, the number of through holes is related to the uniformity of lubrication of the plate, the more the number of through holes, and the distance between the through holes is evenly distributed, the better the uniformity of lubrication of the plate. The upper die base 1 is provided with holes equal in number and positions to the through holes 11 in the upper die, and these holes are communicated with the oil inlet hole 2 provided by the upper die base 1. The joint 10 is connected with an oil delivery pipe 6 with a flow regulating switch 5 , and the other end of the oil delivery pipe is connected with an oil reservoir 4 providing lubricating oil, and the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com