Sealing device

A seal and sensor technology, applied in the field of stamping devices, can solve problems such as lack of positioning, low efficiency, and large space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

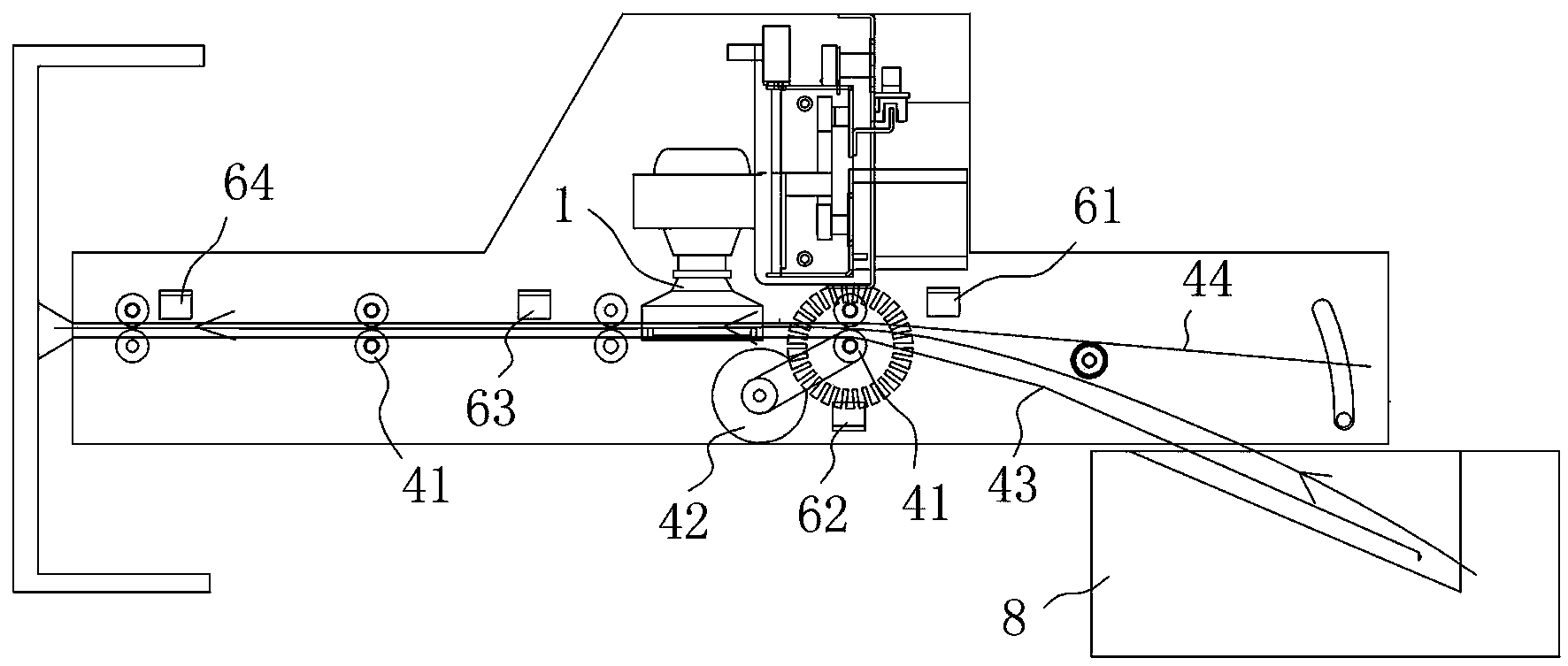

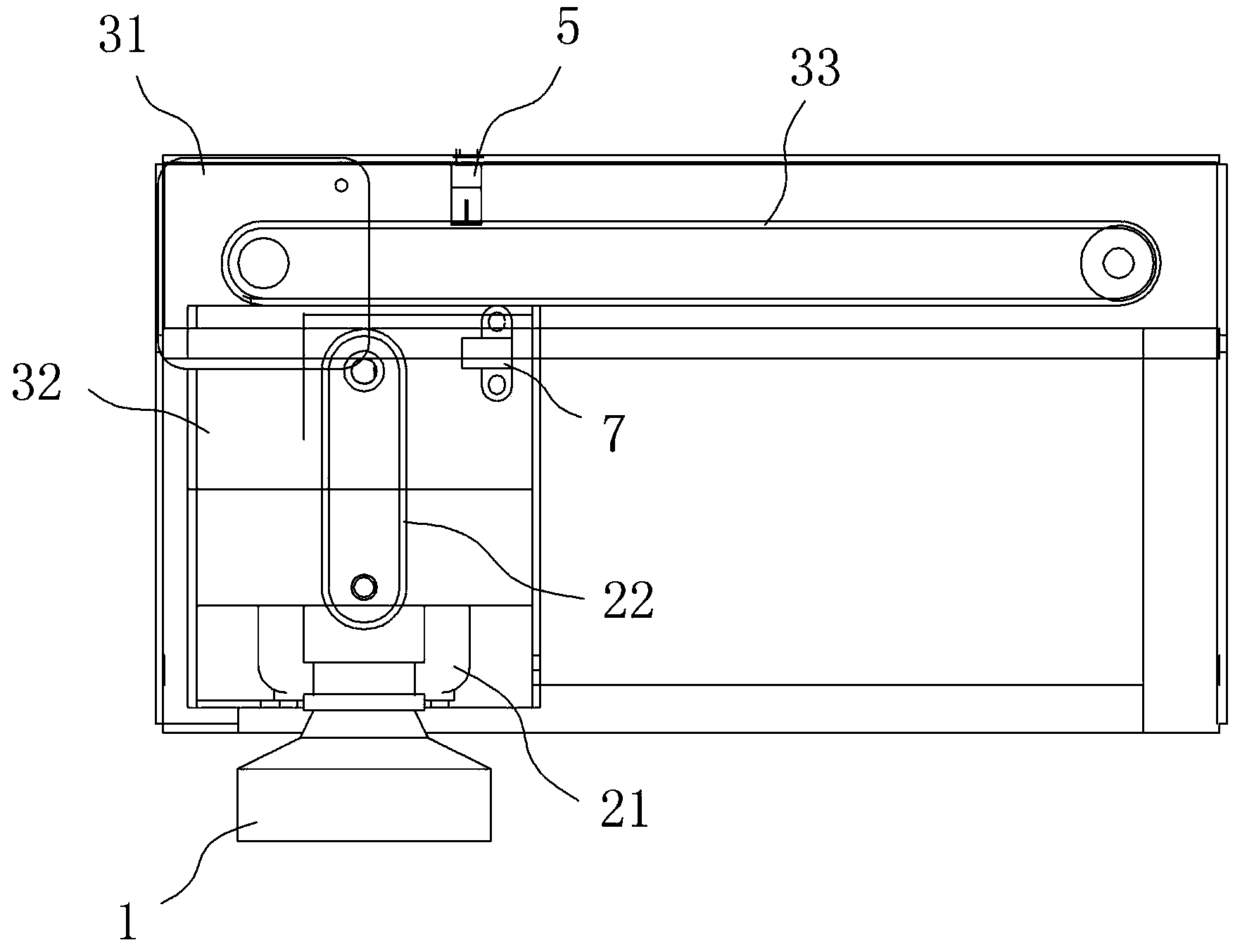

[0011] Embodiment one, such as figure 1 , 2 shown.

[0012] A stamping device, comprising a stamp 1, a lifting mechanism for driving the stamp 1 up and down, a horizontal positioning mechanism for driving the stamp 1 to move horizontally, and a paper feeding mechanism for conveying paper, as well as a stamp position sensor 5, a paper position sensor, and a stamp position sensor 5 Detect the position of the stamp 1 and send the detection signal to the horizontal positioning mechanism for positioning, the paper position sensor detects the position of the paper and send the detection signal to the paper feeding mechanism for positioning.

[0013] The lifting mechanism includes a lifting motor 21, and the lifting motor drives the stamp 1 to lift through the lifting belt 22; there is also a lifting sensor 7 that detects the rising position of the stamp 1, and the lifting sensor detects that the stamp rises to the set position and sends the detection signal to the controller, and t...

Embodiment 2

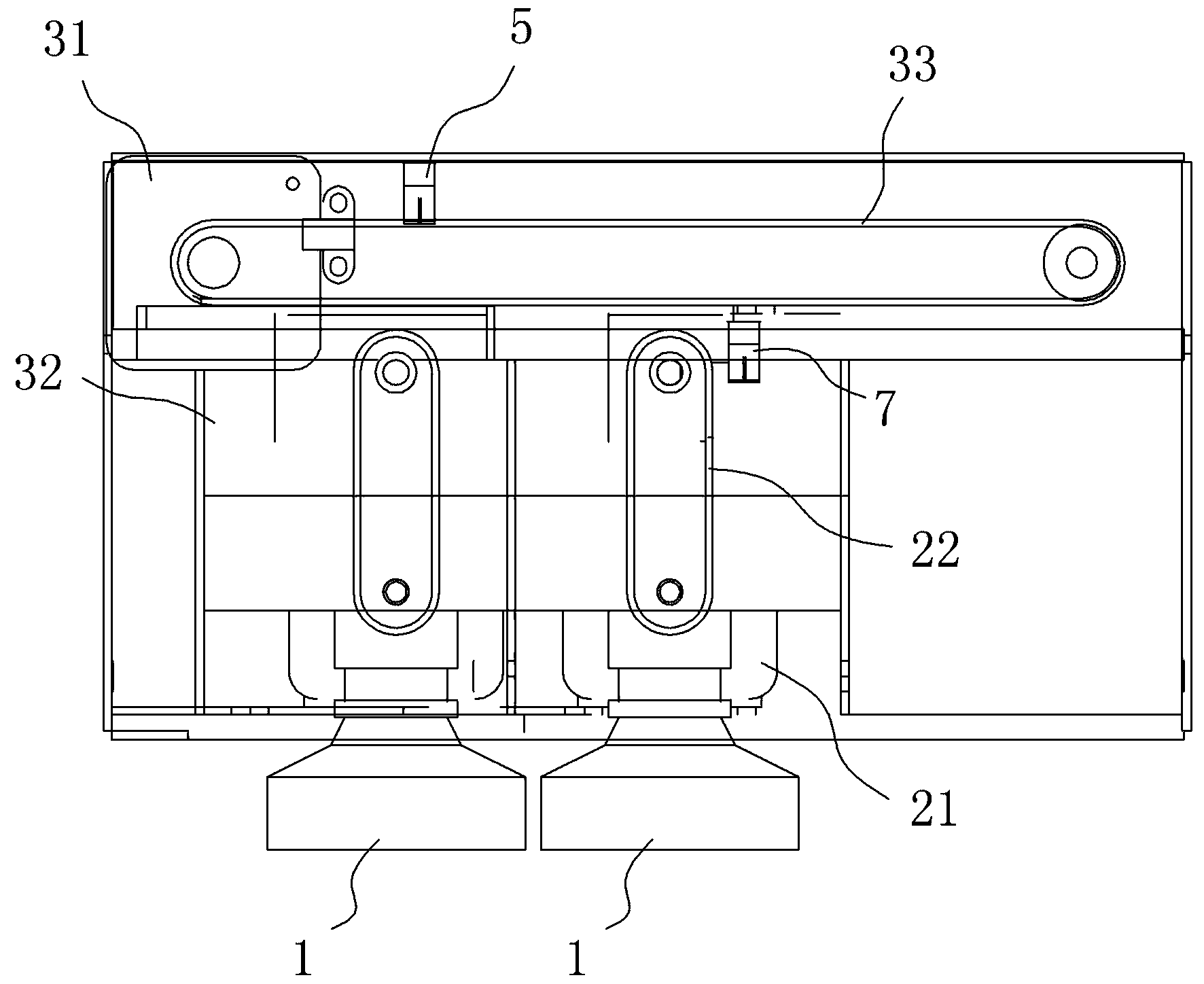

[0019] Embodiment two, such as image 3 shown.

[0020] A stamping device with multiple stamps 1 and multiple elevating mechanisms, each elevating mechanism drives a different stamp 1, and all the stamps 1 are simultaneously driven by a horizontal positioning mechanism to move and position horizontally; multiple stamps 1 are arranged in a row Setting; The rest are the same as in Embodiment 1.

Embodiment 3

[0021] Embodiment three, such as Figure 4 , 5 shown.

[0022] A stamping device has multiple stamps 1 and multiple lifting mechanisms, each lifting mechanism drives a different stamp 1, and all the stamps 1 are simultaneously driven by a horizontal positioning mechanism to move and position horizontally; multiple stamps 1 are set on On the same circumference, and drive all seals to rotate by rotating hanging plate 9; All the other are identical with embodiment one. The stamping device selects the stamp according to the program definition, and selects it through the rotation of the stamp hanging plate, which makes more effective use of space and reduces the size of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com