Sheet metal stamping device with heating function

A stamping device and heating device technology, which is applied in the field of mechanical processing equipment and sheet metal stamping equipment, can solve the problems of reduced production efficiency, cracks, and no detection of sheet metal, so as to improve production efficiency, reduce manufacturing costs, and improve stamping. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

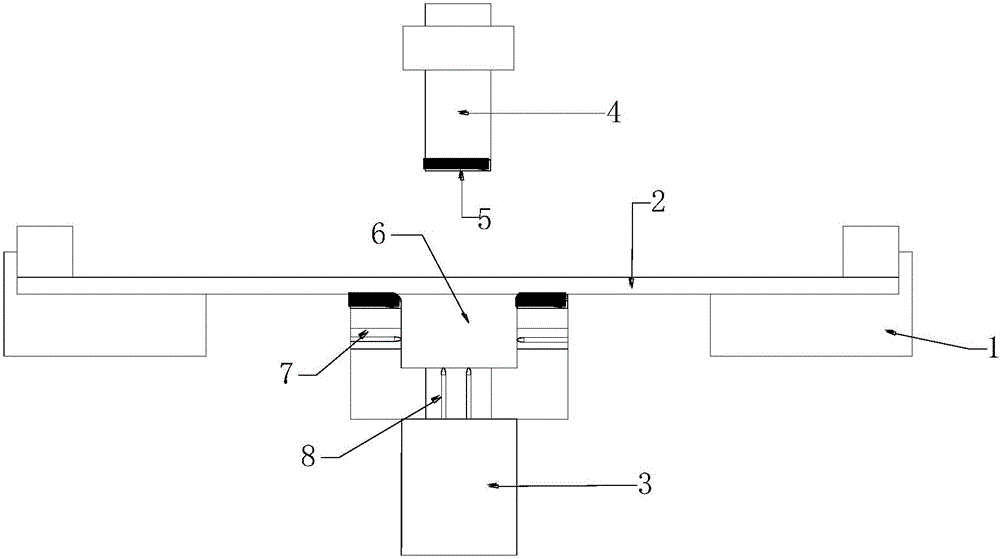

[0017] 1 is a structural schematic diagram of a sheet metal stamping device with a heating function according to the present invention. The following specific embodiments will further illustrate the present invention in conjunction with the above-mentioned drawings.

[0018] The invention relates to a sheet metal stamping device with a heating function, comprising: a sheet metal part 2 is installed horizontally on a stamping support base 1, a stamping die 3 is installed below the sheet metal part 2, and a stamping die 3 is installed above the sheet metal part 2. Head 4; a heating device 5 is installed in the die mouth of the stamping die 3; a heating device 5 is installed in the top of the stamping head 4; a stamping chamber 6 is provided at the upper end of the stamping die 3; the side of the stamping die 3 and The bottom surface is provided with a heat insulating cavity 7 communicating with the stamping cavity 6; an ultrasonic crack detection head 8 is installed in the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com