Headlamp of vehicle

A technology for headlights and vehicles, which is applied to vehicle lighting systems, headlights, vehicle components, etc., can solve the problems of delicate control, difficulty in the shape of light distribution patterns and brightness distribution, and achieve the effect of suppressing glare.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described below with reference to the accompanying drawings.

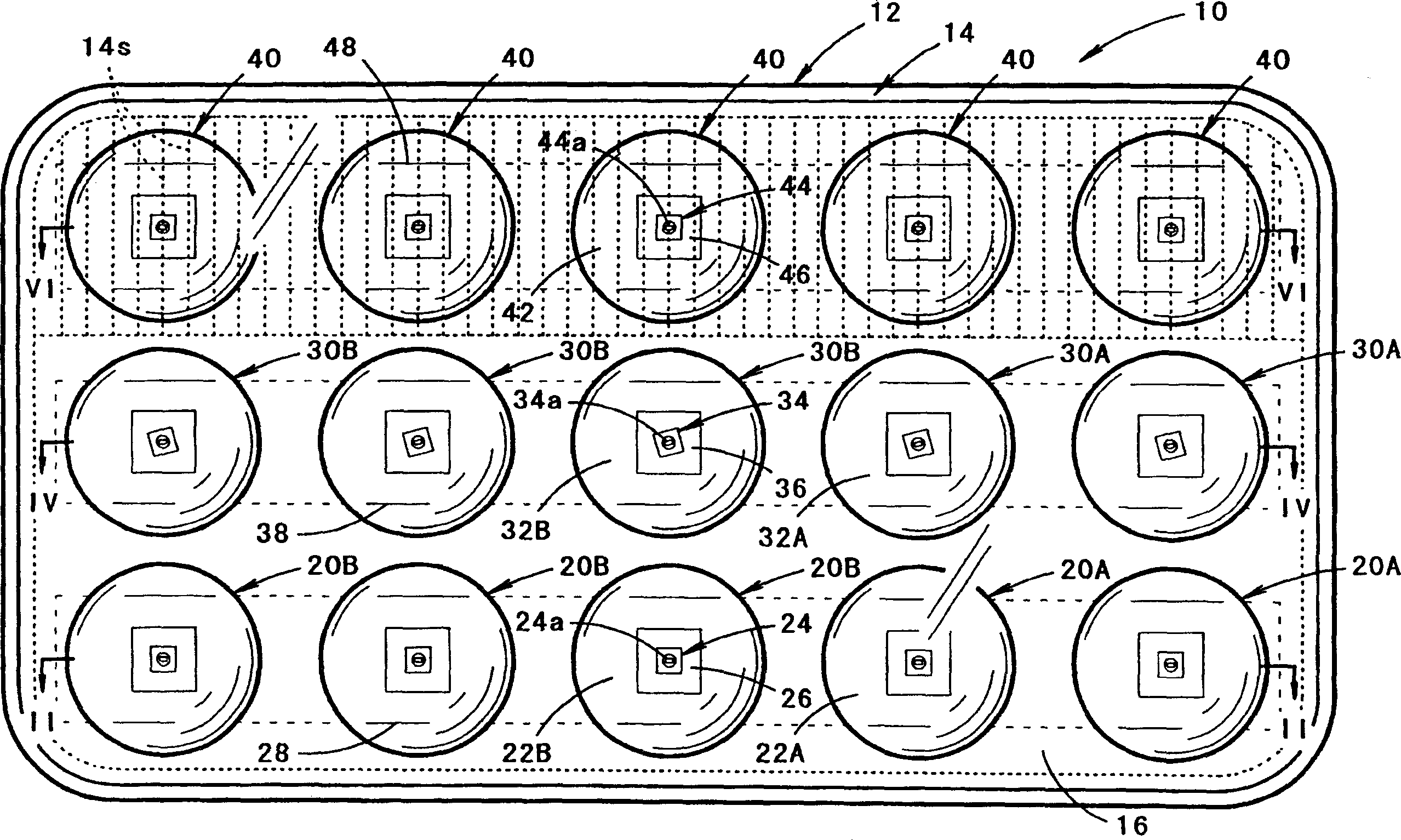

[0031] figure 1 It is a front view showing a vehicle headlamp according to an embodiment of the present invention.

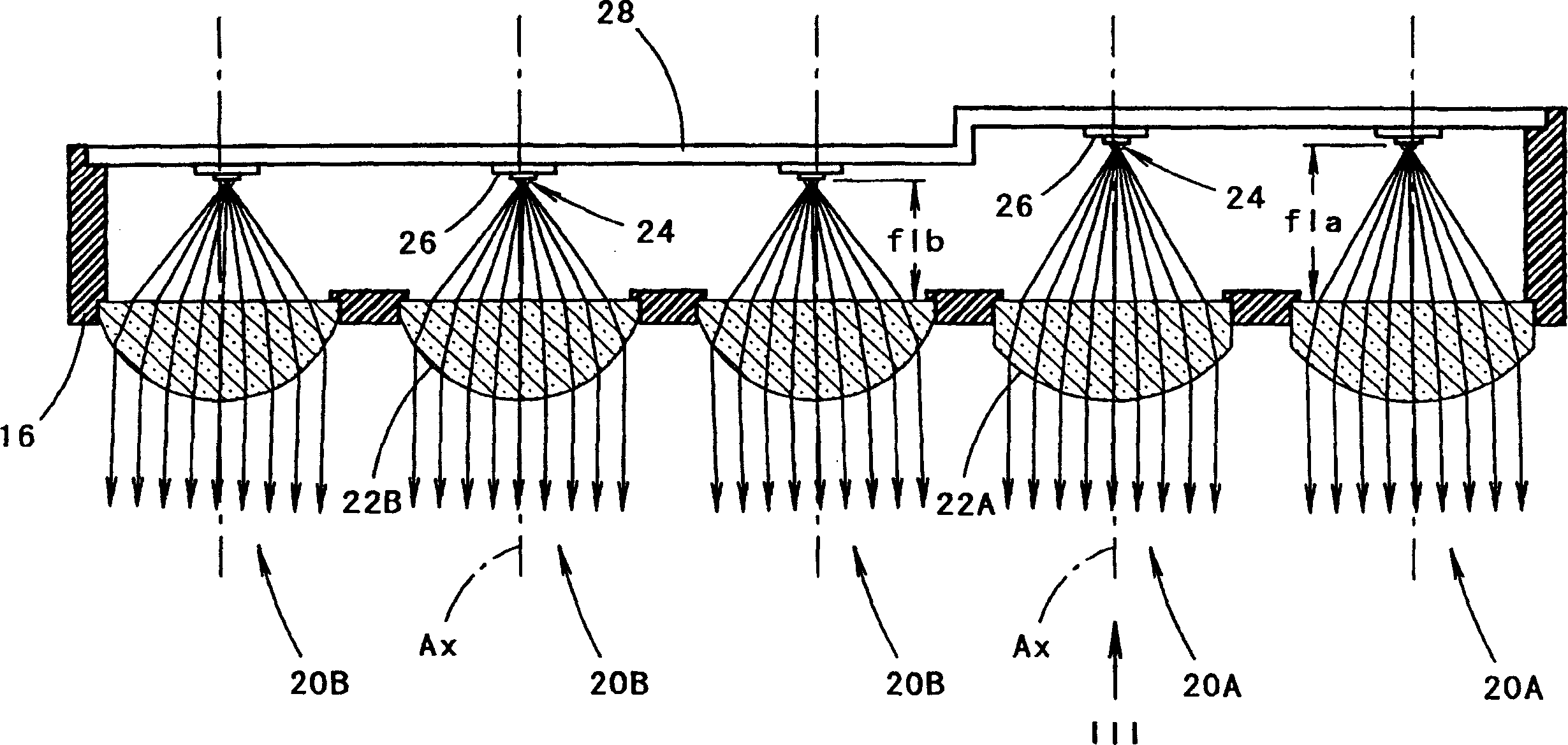

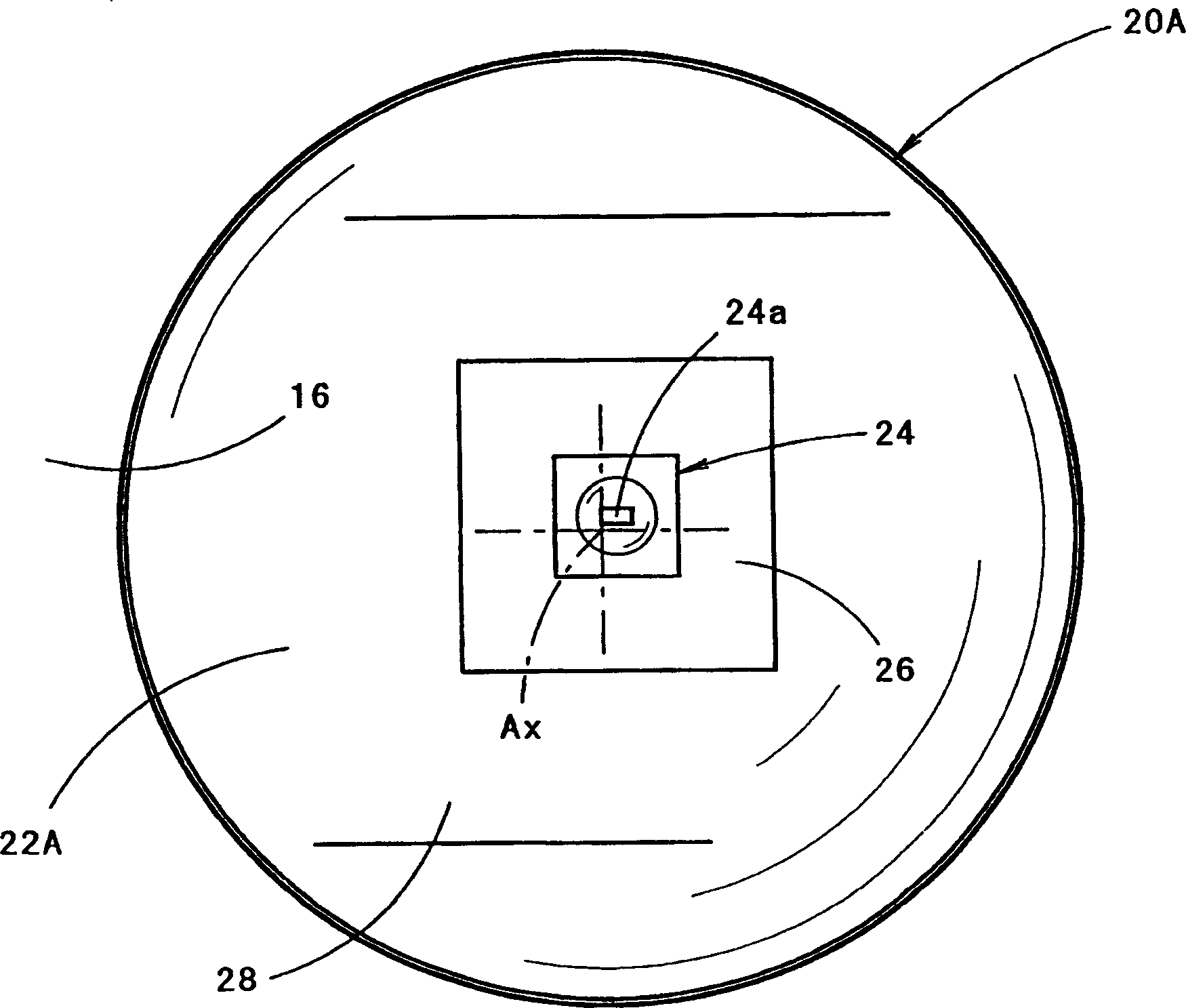

[0032] As shown in the figure, the vehicle headlamp 10 of the present embodiment accommodates 15 lamp units in three upper and lower layers in the lamp chamber formed by the lamp body 12 and the translucent cover 14 attached to the opening at the front end thereof. structure. That is, five first lamp units 20A, 20B are arranged on the lower floor, five second lamp units 30A, 30B are arranged on the middle floor, and five third lamp units 40 are arranged on the upper floor.

[0033] Most of the translucent cover 14 is transparent, and the upper area is formed into vertical stripes by a plurality of diffusion lens elements 14s, which are used to diffuse the illumination light from the five third lamp units 40 located on the upper floor to the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com